HRAT E - HRAT/HRAN

7English 09/02

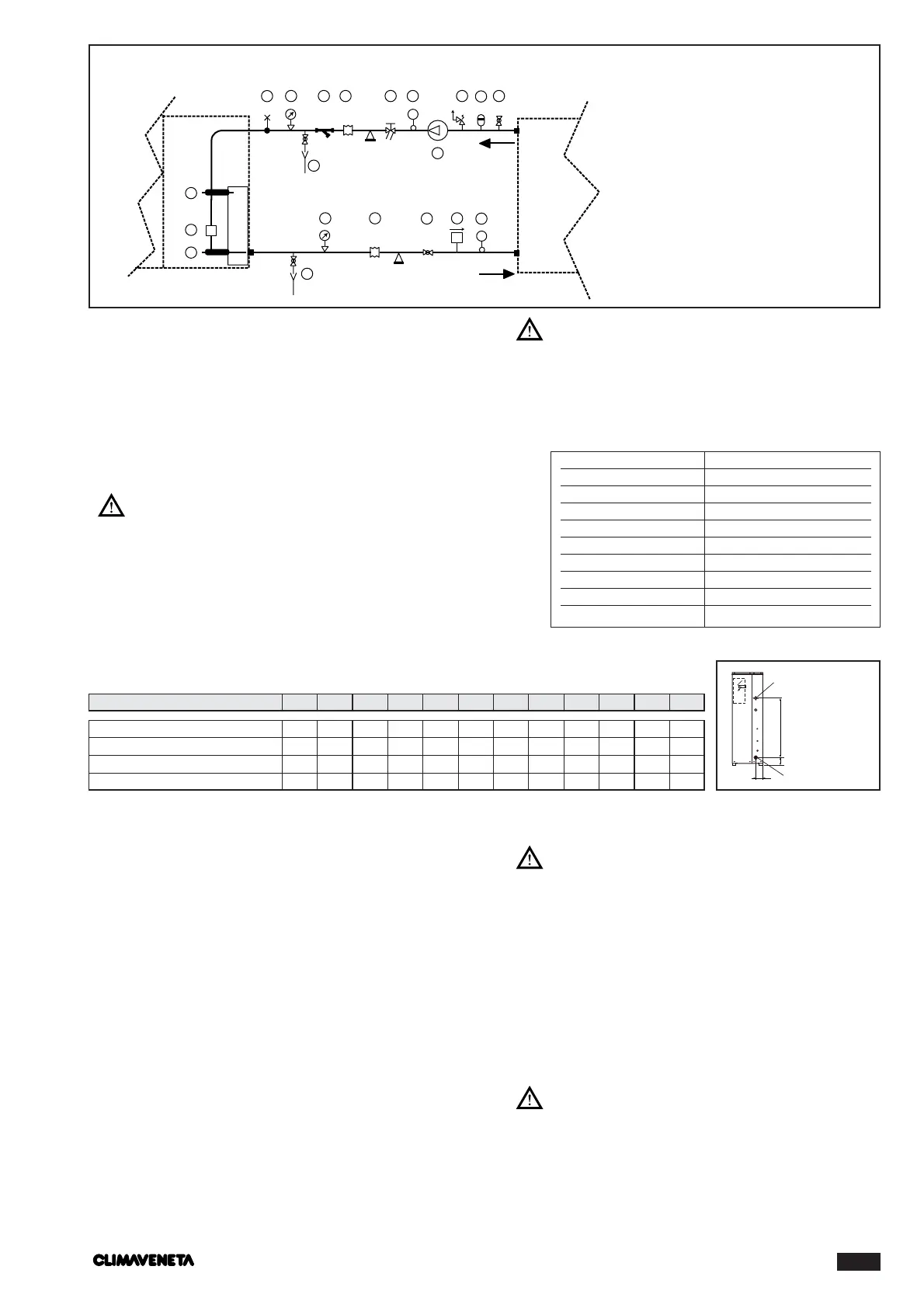

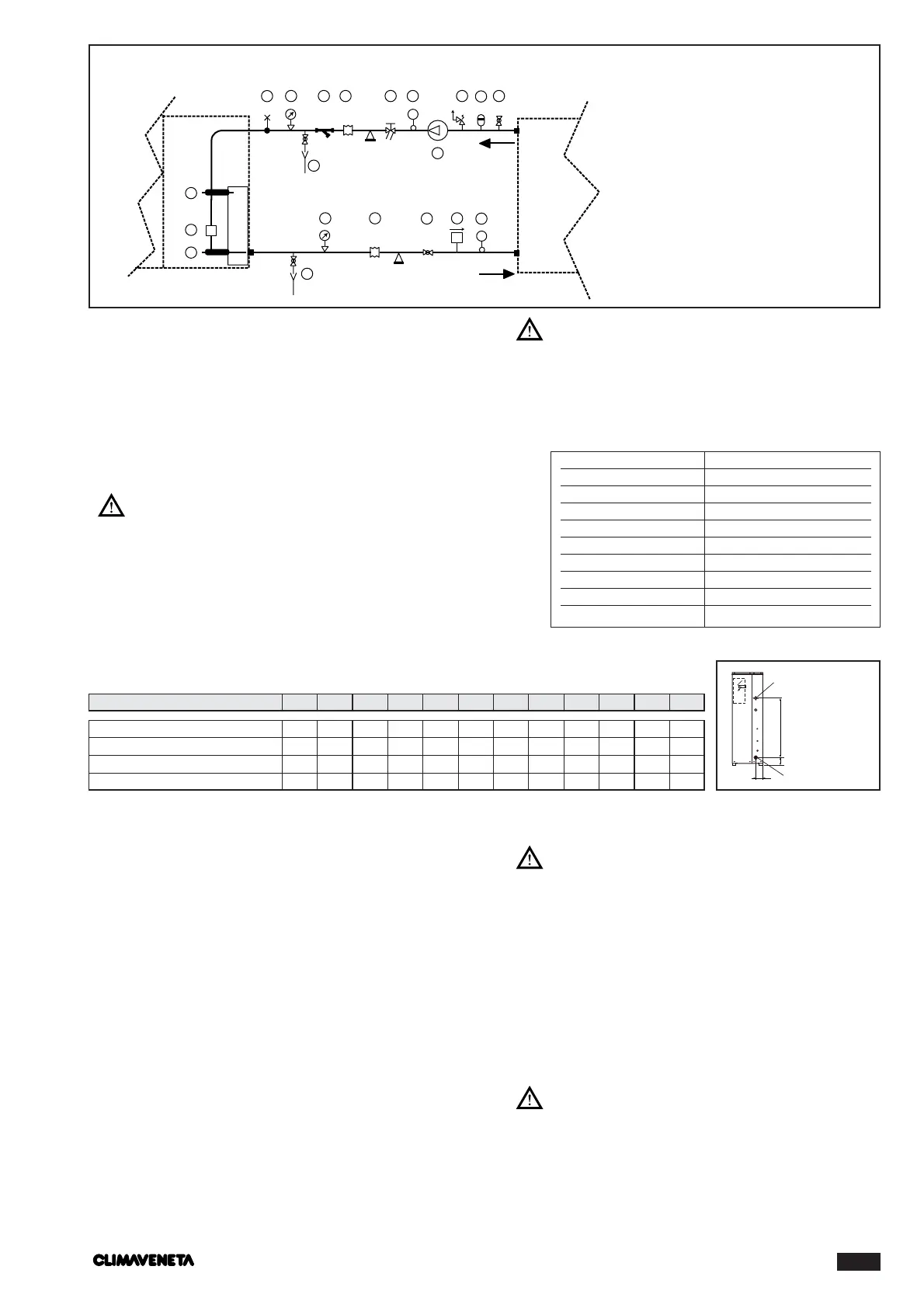

SIZE AND LOCATION OF CONNECTIONS

Model

0011 0021 0025 0031 0041 0051 0061 0071 0091 0101 0121 0151

If the installation requires a useful head higher than that

obtained by installing a pump assembly and storage tank,

it is recommended that an additional pump is installed

on the unit.

The pump can be easily installed on the unit by removing

the special pipe stub provided. Connect to terminal 4, 5

on the electrical panel.

The chillers must be provided with a filling/top-up

system connected to the return line and a drain cock

in the lowest part of the installation. Installations con-

taining anti-freeze or covered by specific legislation

must be fitted with hydraulic disconnectors.

The manufacturer is not liable for obstruction,

breakage or noise resulting from the failure to

install filters or vibration dampers.

Particular types of water used for filling or top-

ping up must be treated with appropriate treatment

systems. For reference values, see the table.

FILLING THE INSTALLATION

- Before filling, check that the installation drain cock is

closed.

- Open all installation and terminal air vents.

-Open the gate valves.

- Begin filling, slowly opening the water filling cock outside

the unit.

-When water begins to leak out of the air vent valves of

the terminals, close them and continue filling until the

pressure gauge indicates a pressure of 1.5 bars.

The installation must be filled to a pressure of

between 1 and 2 bars.

It is recommended that this operation be repeat-

ed after the unit has been operating for a number

of hours.The pressure of the installation should be

checked regularly and if it drops below 1 bar, the

water content should be topped-up.

Check hydraulic connections for tightness.

PH 6-8

Electrical conductivity less than 200 mV/cm (25°C)

Chlorine ions less than 50 ppm

Sulphuric acid ions less than 50 ppm

To tal iron less than 0,3 ppm

Alkalinity M less than 50 ppm

Total hardness less than 50 ppm

Sulphur ions nil

Ammonia ions nil

Silicon ions less than 30 ppm

EMPTYING THE INSTALLATION

- Before emptying, place the general installation switch in

the “off” position.

- Make sure the installation fill/top-up water cock is

closed.

-Open the drain cock outside the unit and all the installa-

tion and terminal air vent valves.

If the fluid in the circuit contains anti-freeze,

it should be not be allowed to drain freely as it is

pollutant. It should be collected for possible reuse.

Loading...

Loading...