25

Notions on refrigerant piping connection

6 NOTIONS ON REFRIGERANT PIPING CONNECTION

The length of the refrigerant pipes aects performance and energy eciency of the unit. The nominal eciency is tested

on units whose pipes are 5 meters long.

For tropical areas, the maximum length of the coolant pipe must not exceed 10 metres. Refer to the following table for

specifications on maximum pipe length and height dierence

27M 35M 53M 70M

Max equivalent length m 25 25 30 50

Max. height dierence Outdoor unit / Indoor unit m ±10 ±10 ±20 ±25

6.1 Refrigerant piping connections

6.1.1 Cut the pipes

When preparing the coolant pipes, take great care to

cut and flare them correctly. This will ensure ecient

operation and reduce the need for further maintenance.

For units with R32 refrigerant, the pipe connection

points must be outside the room.

1 Measure the distance between the indoor and

outdoor unit.

2 Using a pipe cutter, cut the pipe to a measurement

slightly longer than the measured distance.

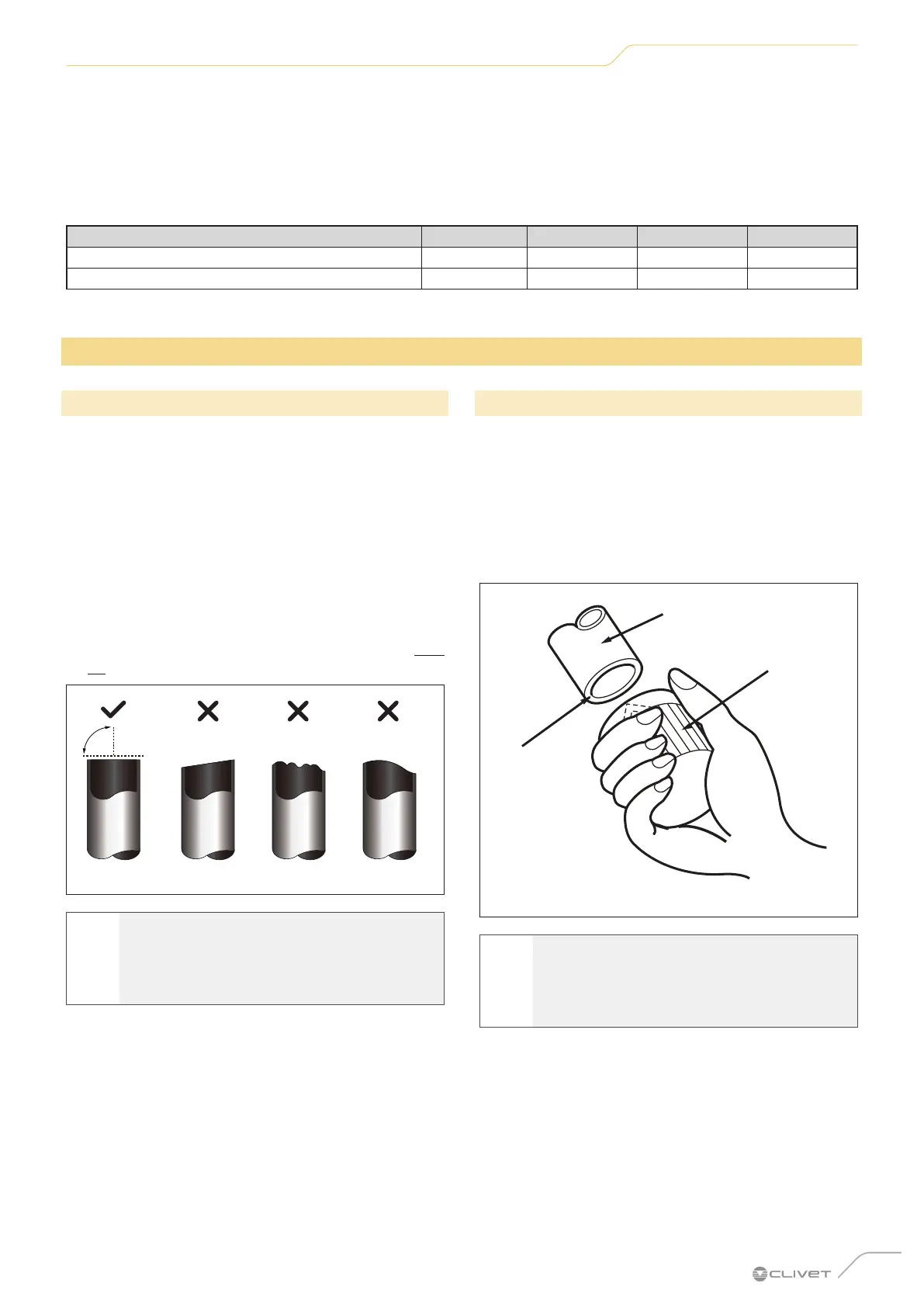

3 Check that the pipe is cut at an exact 90° angle. Refer

to the examples of incorrect cutting contained in “Fig.

14”.

90°

Oblique Irregular Corrugated

Fig. 14

m

CAUTION

Do not damage, tighten or deform the pipe

during cutting. This would greatly reduce the

heating eciency of the unit.

6.1.2 Eliminate smudges

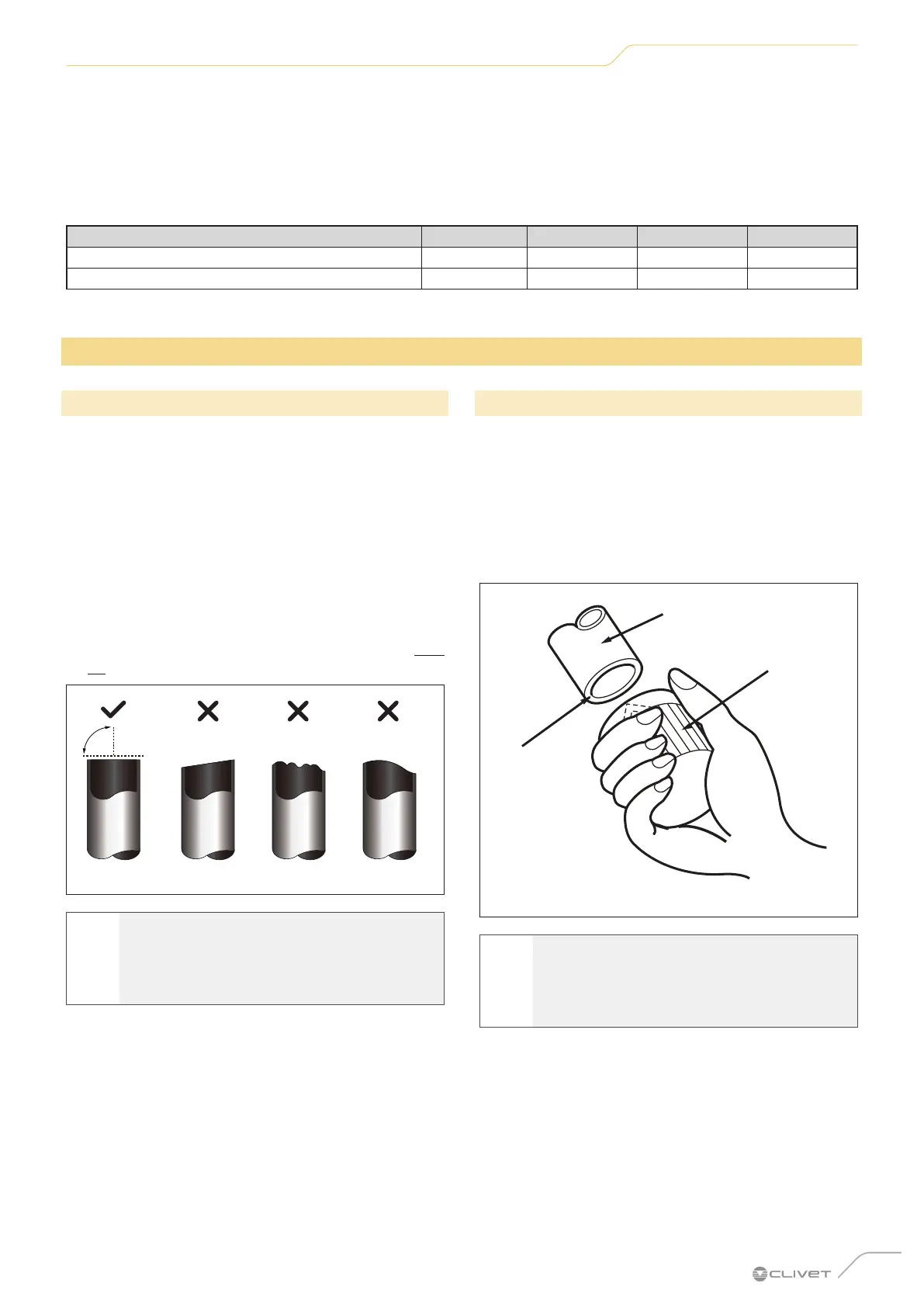

Deburring can make the refrigerant piping connection

seal less eective. For this reason, they must be

eliminated completely.

1 Keep the pipe tilted downwards to prevent debris

residue from falling into the pipe.

2 Using a reamer or similar tool, remove all burrs from

the cut section of the pipe.

Pipe

Reamer

Tilt downward

Fig. 15

m

CAUTION

Do not damage, tighten or deform the pipe

during cutting. This would greatly reduce the

heating eciency of the unit.

Loading...

Loading...