22

Electrical connections

Refer to the tables below for power cable specifications.

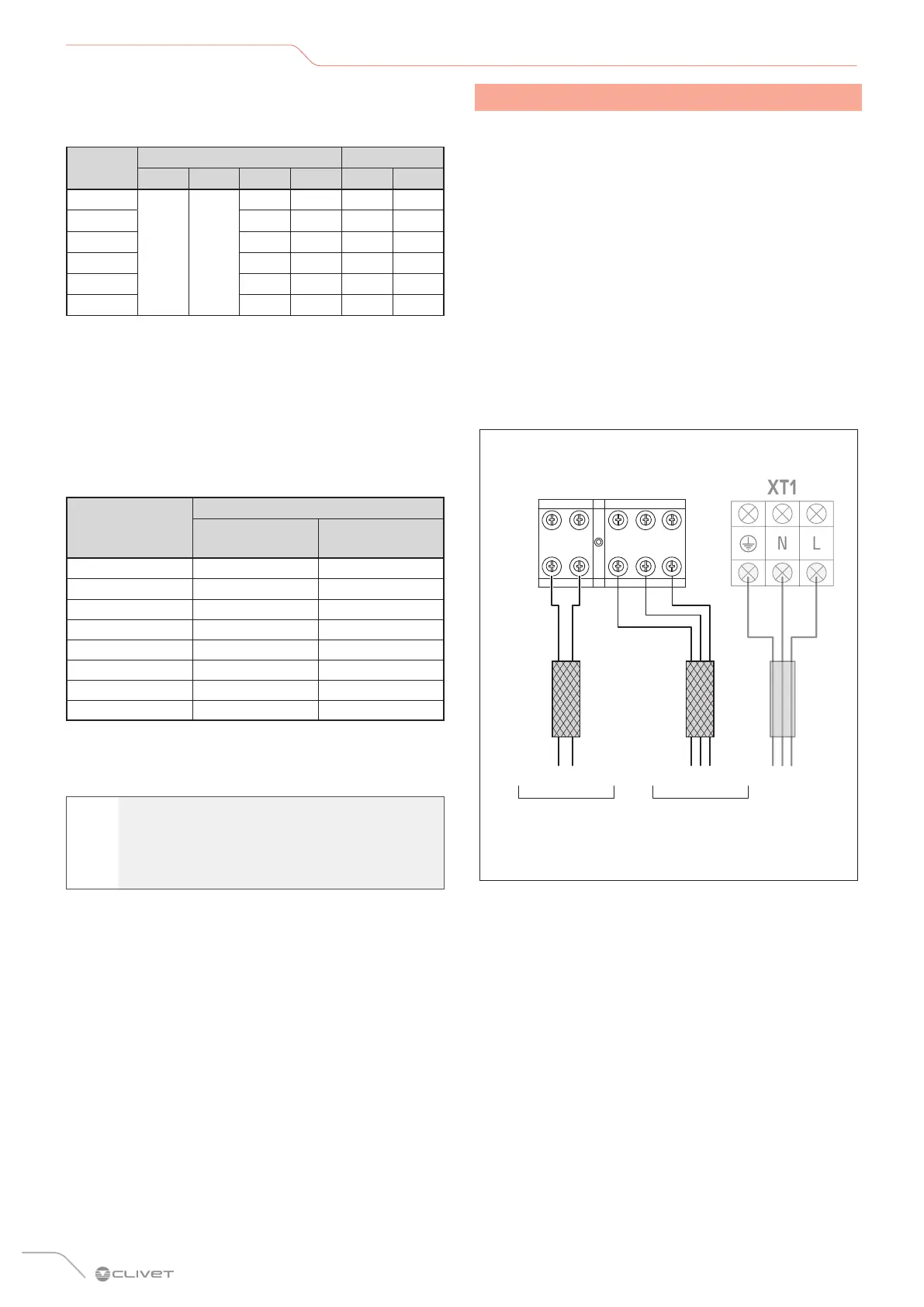

Electrical characteristics of indoor units

Capacity

Power supply IFM

Hz Volts MCA MFA kW FLA

1.7 kW

50

50/60

220-

240

0.42 15 0.37 0.344

2.2kW 0.43 15 0.37 0.344

2.8kW 0.43 15 0.37 0.344

3.6kW 0.48 15 0.37 0.344

4.5kW 0.48 15 0.37 0.344

5.2KW 0.60 15 0.37 0.344

Abbreviations:

MCA: Minimum circuit Amps

MFA: Maximum fuse Amps

IFM: Indoor unit fan motor

kW: Motor rated power

FLA: Full load Amps

1 Select the individual cable diameters (minimum value)

for each unit based on the table below:

Rated current

of the appliance

(A)

Nominal section area (mm

2

)

Flexible cables

Fixed wiring

cable

≤ 3 0.5< ... ≥0.75 1< ... ≥2.5

3< ... ≥6 0.75< ... ≥1 1< ... ≥2.5

6< ... ≥10 1< ... ≥1.5 1< ... ≥2.5

10< ... ≥16 1.5< ... ≥2.5 1.5< ... ≥4

16< ... ≥25 2.5< ... ≥4 2.5< ... ≥6

25< ... ≥32 4< ... ≥6 4< ... ≥10

32< ... ≥50 6< ... ≥10 6< ... ≥16

50< ... ≥63 10< ... ≥16 10< ... ≥25

2 The maximum permissible variation of the voltage

range between phases is 2%.

l

WARNING

Choose the power cable and wiring with reference

to the laws and regulations in force. Assign a

professional to choose and install the wiring.

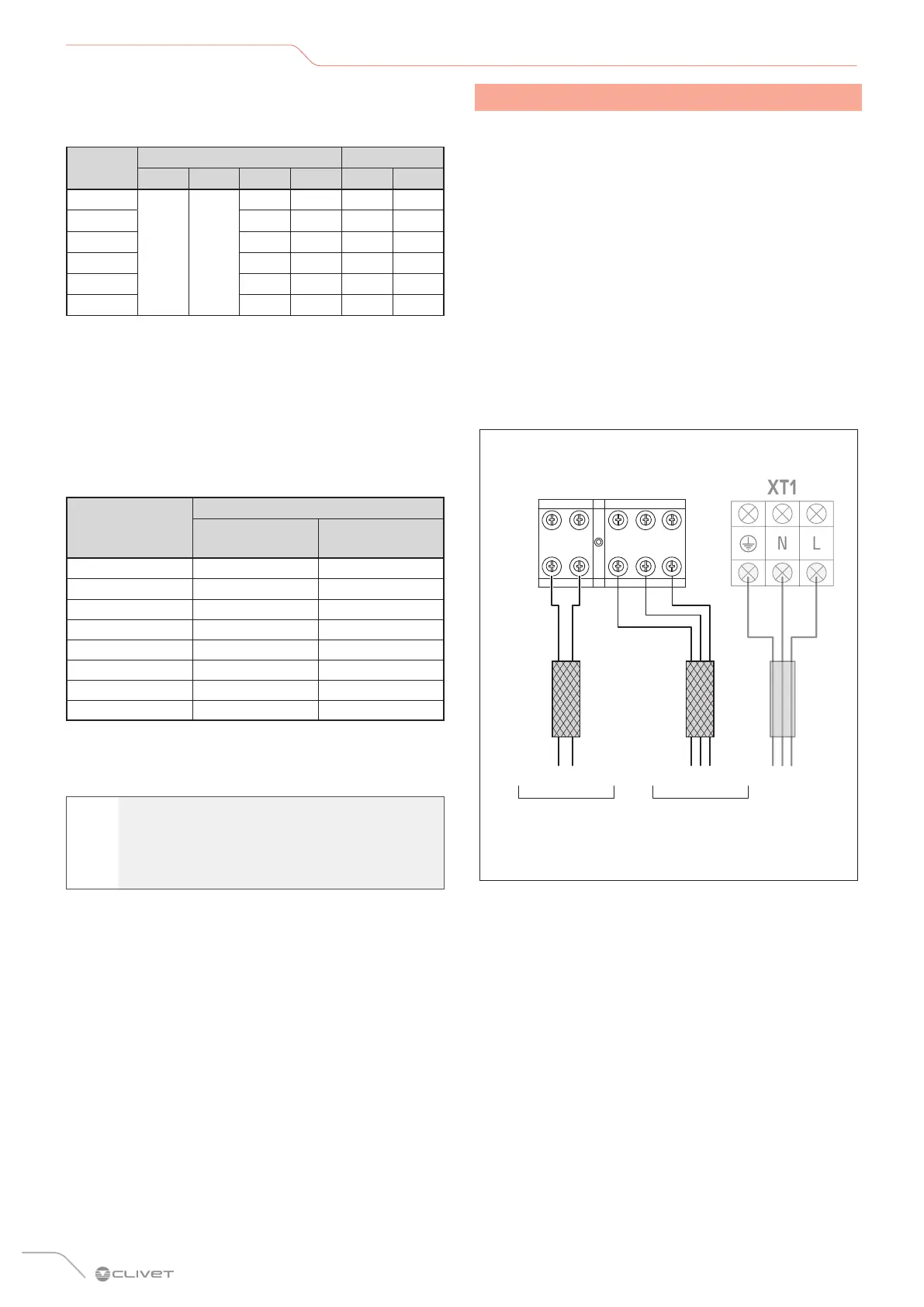

3.3 Communication wiring

– Only use shielded cables for communication wiring.

Any other type of cable can produce interference

between signals, causing the units to malfunction.

– Do not carry out electrical work such as welding

with the equipment switched on.

– All shielded wiring in the network is interconnected,

and possibly earthed at the same point.

– Do not tie refrigerant pipes, power cables and

communication cables together. If the power

cable and communication wiring are parallel, the

distance between the two lines must be 300 mm

or more to prevent signal source interference.

– The communication wiring must not form a closed

circuit.

X2

X1

E

Q P

INDOOR unit terminal blocks

Signal (BUS) Signal (BUS)

to the wired

controller’s terminal

block

from the unit’s

terminal blocks

Fig. 25

Loading...

Loading...