M03I40M7-03 15/11/07 page 17

SYSTEM MEASURES ON SOURCE SIDE

FILTER

It is very important for the water to be free of impurities. If it

is not, the efficiency of thermal exchange is diminished. In

the worst cases, the exchanger can be irreparably

damaged. The filter, if not present on-board the machine,

must be installed immediately upstream from the unit, in a

position that is easily accessible for cleaning

FLOW SWITCH

Since it is a system component, it must always be included,

in order to ensure unit shutdown in the event of failure of

water circulation. It is to be installed in a straight section of

the pipes, and not near curves which generate harmful

turbulence.

ANTI-FREEZE SOLUTIONS

For use of the unit with ambient temperatures near 0°C,

use antifreeze solutions such as ethylene glycol to prevent

the formation of ice. Its use is also required when

geothermal probes are used.

SYSTEM WASHING

Before connecting the unit, carefully wash the system by

filling it and emptying it several times with clean water.

CONTROL OF FLOW RATE

This makes it possible to limit water consumption, increase

energy efficiency and extend the unit's operating limits.

It can be modified by using

1. Modulating motorized valve

2. Cut-off valve

3. Pressure switch valve

CUT-OFF VALVE

This allows cut-off of water on the source side whenever

the compressor is not running.

It is therefore advisable for systems with disposable water,

if there is no modulating valve

8

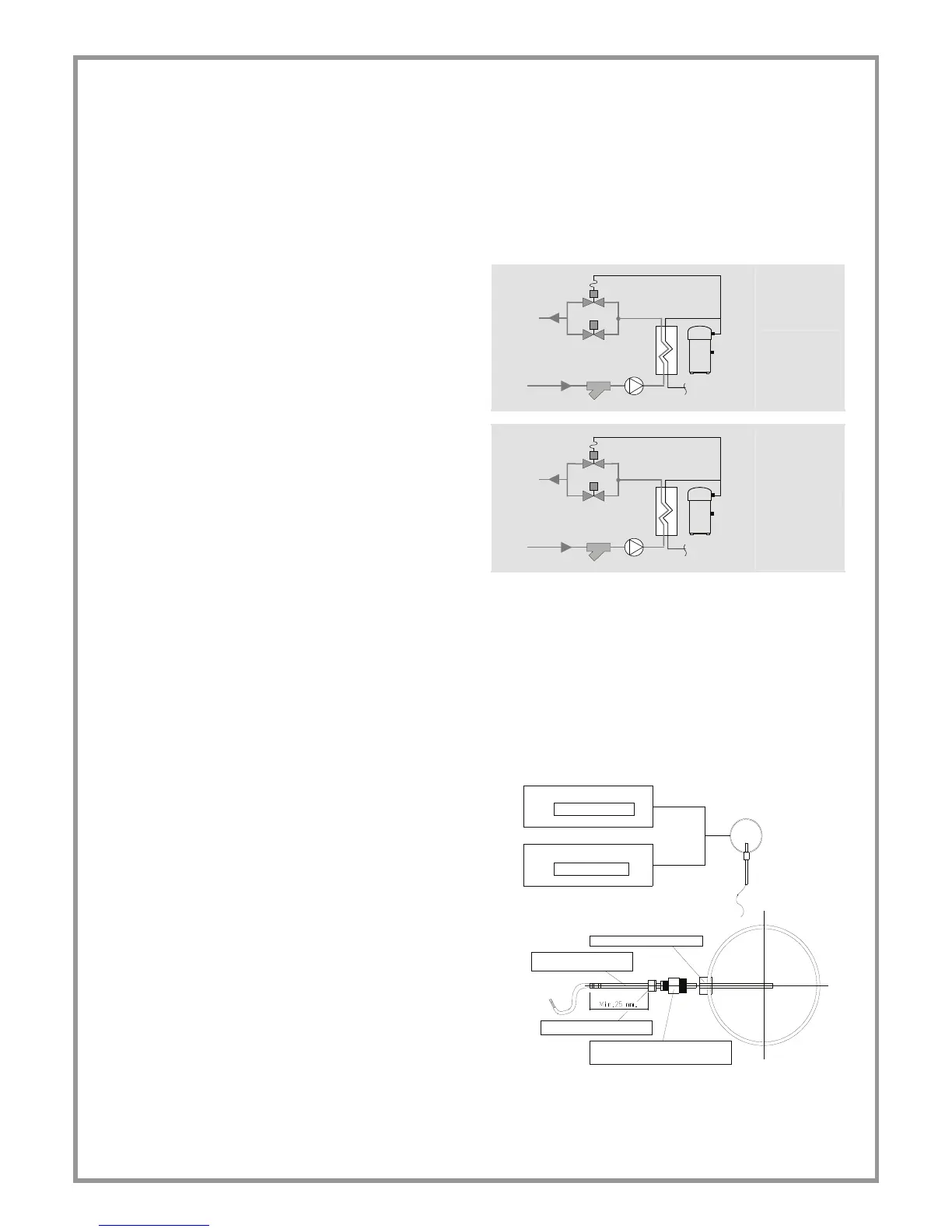

BY

PR

C1

8

BY

PR

C2

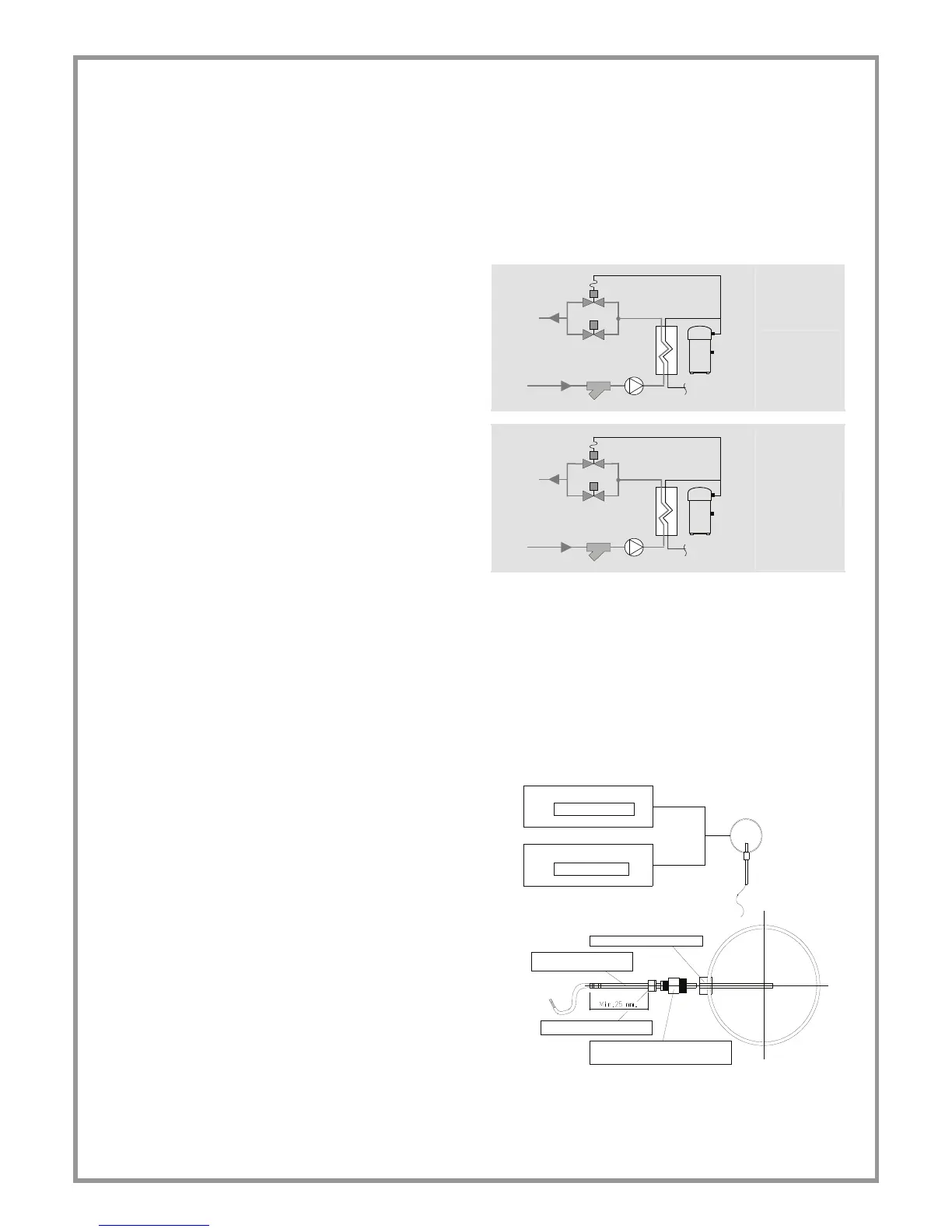

BT3-BT4 TEMPERATURE PROBES OF WDHH UNIT

These probes, with respective connection, are supplied with

the unit and they must be fitted as specified in the drawing.

CIRC 1 CONDENS.

CIRC 2 CONDENS.

SLEEVE 1/2” (not supplied)

NTC TEMPERATURE PROBE

OF IP67 TIN

PROBE FIXATION NUT

Scrolling CONNECTION 6mm 1/2” in brass

and sealed O-RING

Loading...

Loading...