14

Water connections

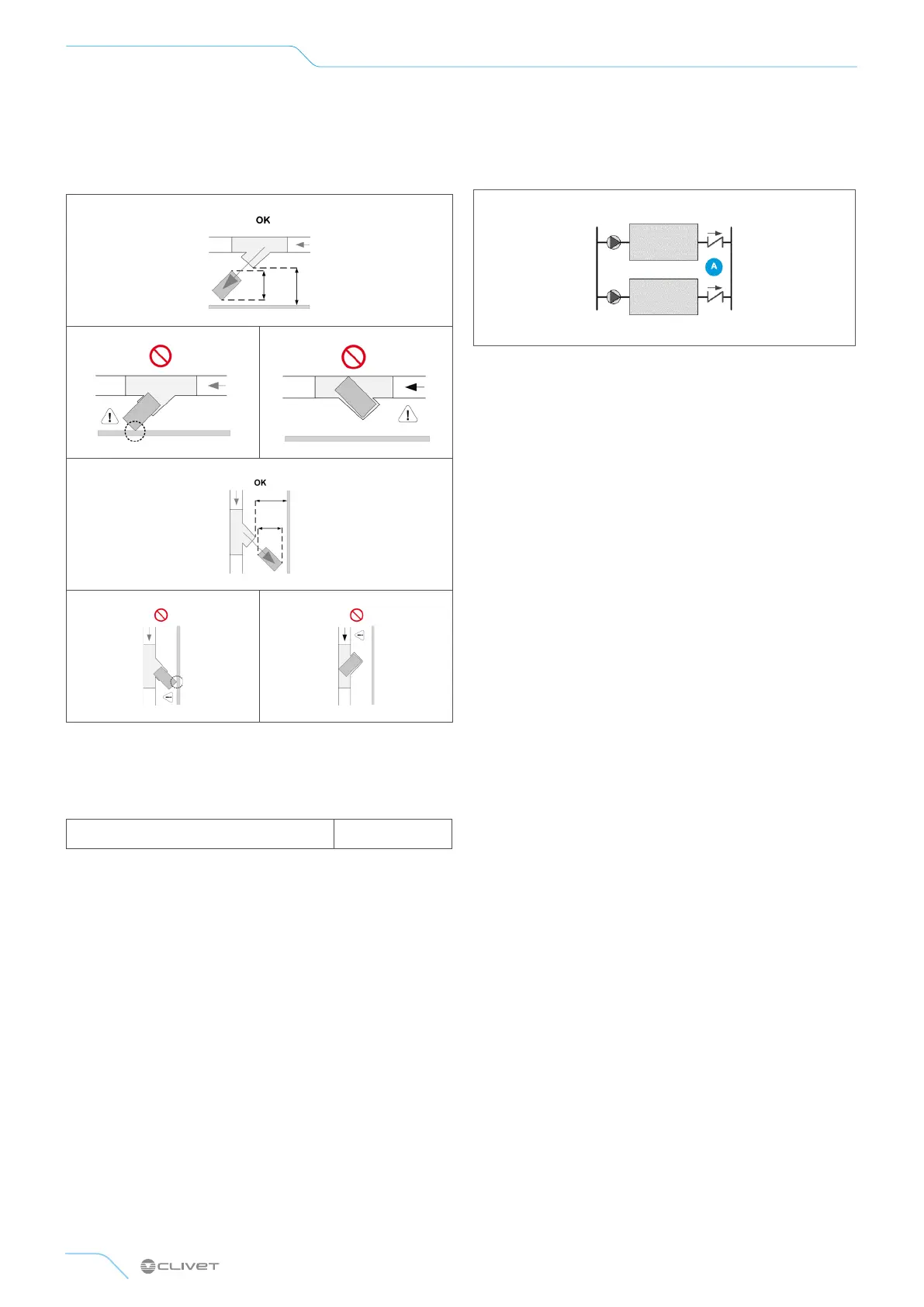

6.11 Water filter

Must be installed immediately in the water input of the

unit, in a position that is easily accessible for cleaning.

The filter must have an adequate mesh to prevent the

entry of particles grater that:

plate exchanger (mm) 1,6

ATTENTION

⊲ The filter never should be removed, this operation

invalidates the guaranty.

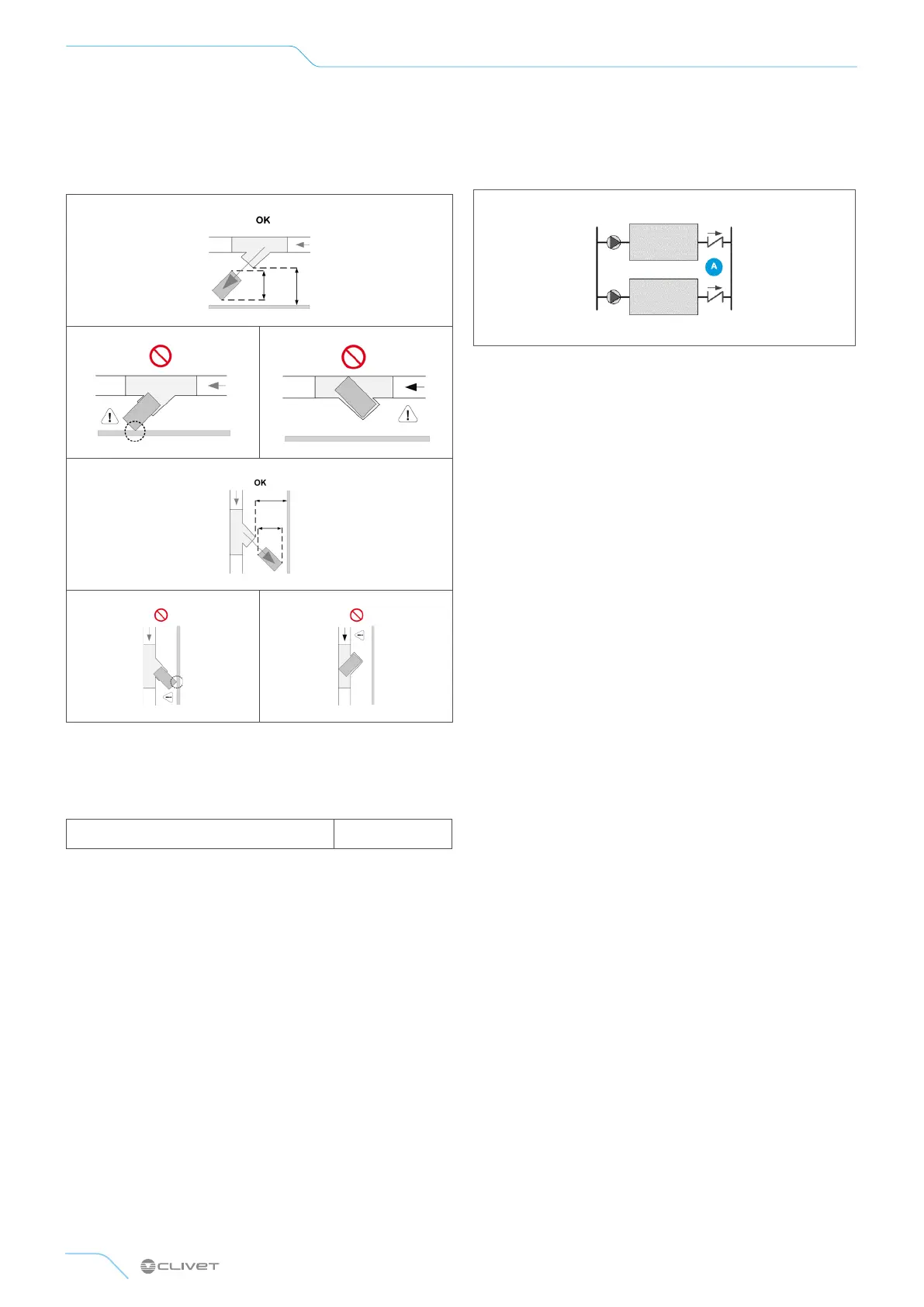

6.12 Non-return valve

Provide for the installation of non-return valves (A) in the

case of several units connected in parallel.

6.13 Operation sequence

Before starting the unit pump:

1 Close all vent valves in the high points of the unit

hydraulic circuit

2 Close all drain shut-o valves in the low points of

the unit’s water circuit

exchangers

pumps

collectors

storage tanks

3 Carefully wash the system with clean water: fill and

drain the system several times.

4 use the bypass to exclude the exchanger from the

flow (diagram on the previous page)

5 fill and empty the system multiple times.

6 Apply additives to prevent corrosion, fouling,

formation of mud and algae.

7 Fill the plant

8 do not use the unit pump.

9 Execute leakage test.

10 Isolate the pipes to avoid heat dispersions and

formation of condensate.

Leave various service points free (wells, vents, etc).

ATTENTION

⊲ Neglecting the washing will lead to several filter

cleaning interventions and at worst cases can cause

damages to the exchangers and the other parts.

6.14 Hydronic units and connection diagrams

recommended

The installer must define:

• type of components

• position in the system

See diagrams on the next pages.

Loading...

Loading...