M02R40C8-00 29/07/08 page 22

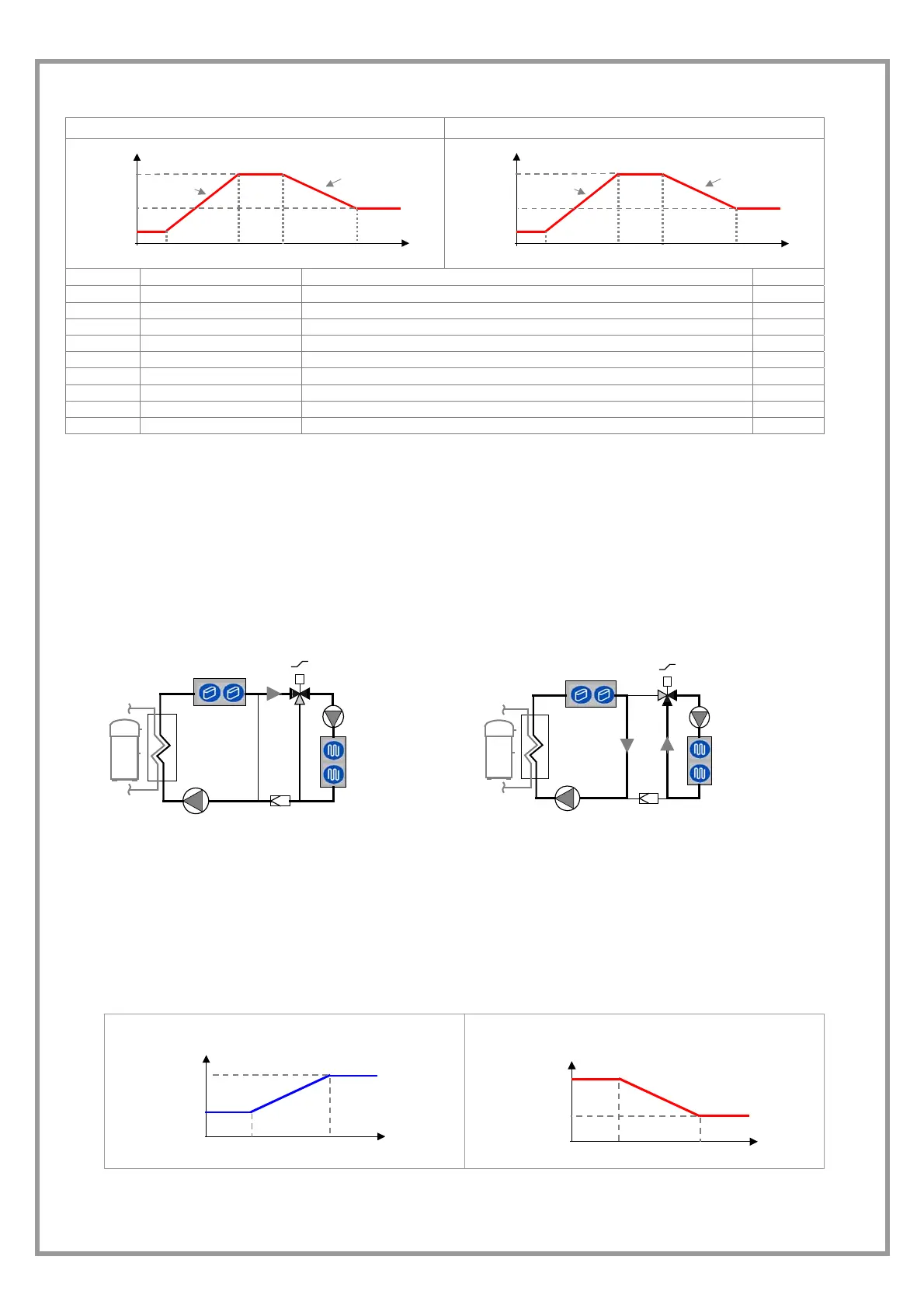

PARAMETERS INDICATIVE VALUES

T EXT

P 12

P 13

SET POINT

40 °C

37 °C

P 175

P 74 P 160

A

B

T EXT

15°C

7 °C

SET POINT

40 °C

37 °C

35 °C

-2 °C-15 °C

A

B

par Description Meaning value

12 CextMaxH Ext. Temp. max. winter correction 15

13 CextMinH Ext. Temp. min. winter correction 0

73 EnLimiteTExtH Enable corr. SP Heat for external air limit 0

74 TlimiteMaxH Outside temperature for max SP Heat -5

115 CompExtH2OS Enable comp. for External Temp. of the domestic hot water set point 0

116 MaxCompH2OS Maximum outside T correction for domestic hot water set point 10

152 TextEn EXT. Air probe presence 1=YES, 0=NO

160 TlimiteMinH Outside temperature for min SP Heat -15

175 MinSetLimiteH Minimum value that can be set for SP Heat 35

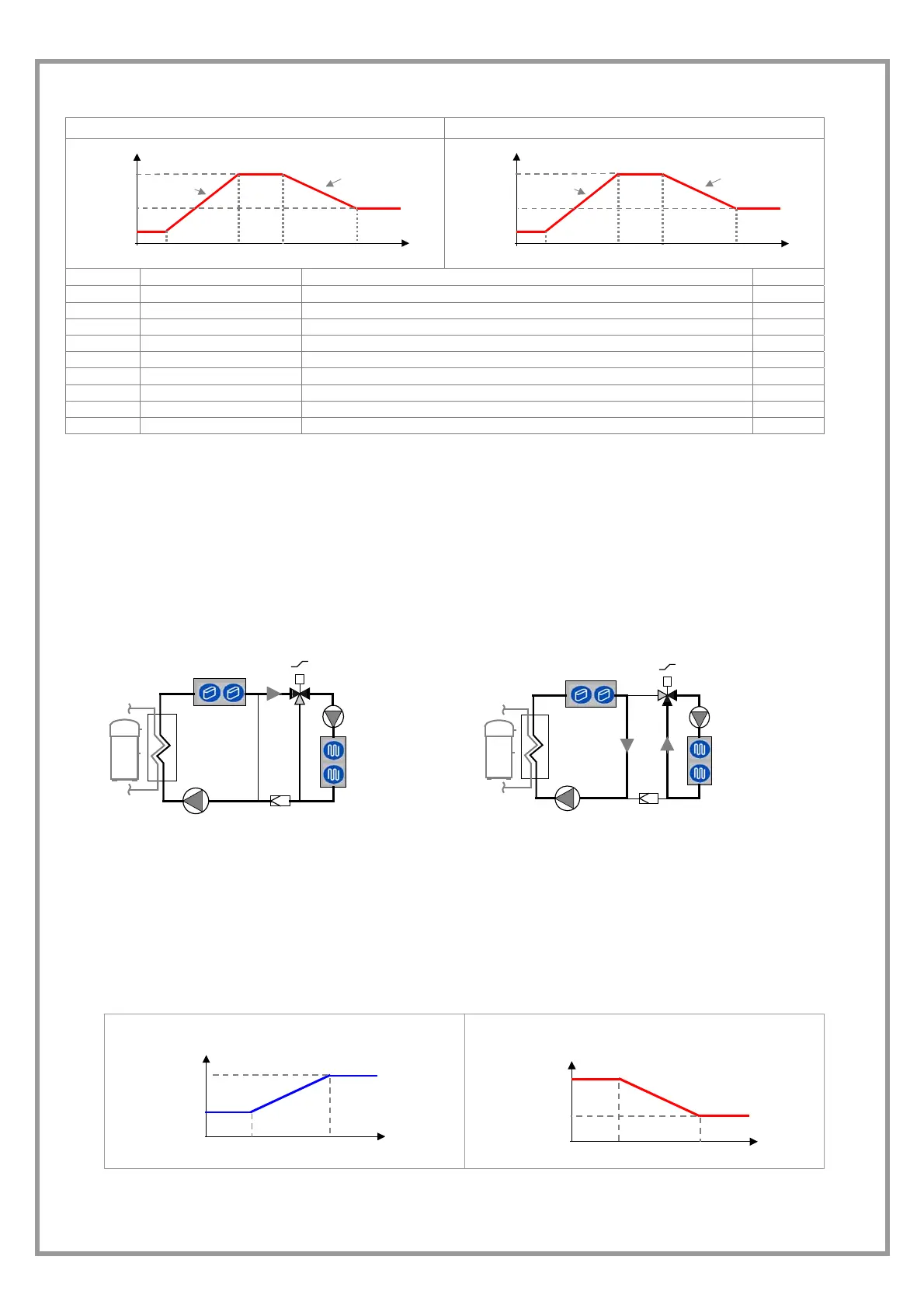

9. DUAL CONTROLS FOR TEMPERATURE – RADIANT PANELS

It is necessary the expansion plug-in module that must be fitted by the client (r refer to the kit instructions) and enabled by

parameter 140 = 1.

With the optional kit, the mixed elements can be controlled: fan coils + radiant panels:

• Radiant panel circulator

• Mixing valve (0-10 volt or ON-OFF)

• Delivery probe (NTC type, 10 Kohm at 25°C)

• External control: COOLING/HEATING LIMIT (avoids dew / overheating).

ATTENTION: to prevent dew in summer or superheating in winter, it is very important to fit an external device and interface it

with the unit that in case of signalling will force the recycling valve on the radiant panels

BLEEDING BY CHILLER RADIANTS IN RECYCLING

8

7°

12°

18°

23°

8

7°

12°

18°

23°

Output status on the optional plug-in module

valv 0-10 10 volt valv 0-10 0 volt

out 22-23 = ON out 22-23 = OFF

3-point valve

out 22-25 = OFF

3-point

valve

out 22-25 = ON

The water set point at the radiant panels can be managed in three ways:

1. the valve is managed to maintain the outlet temperature at par 192 value, independently of the unit operating mode

(COOLING or HEATING).

2. calculated automatically in function of the external air temperature; two set are calculated (HEAT. / COOL.) that

become actives on the basis of the unit operating mode. This configuration is obtained setting par 190=1

COOLING HEATING

P 197

P 196

ET P

INT

T EXT

P 195

P 194

T EXT

P 201

P 200

SET POINT

P 199

P 198

Loading...

Loading...