6 • Important: Always read and follow the operating instructions.

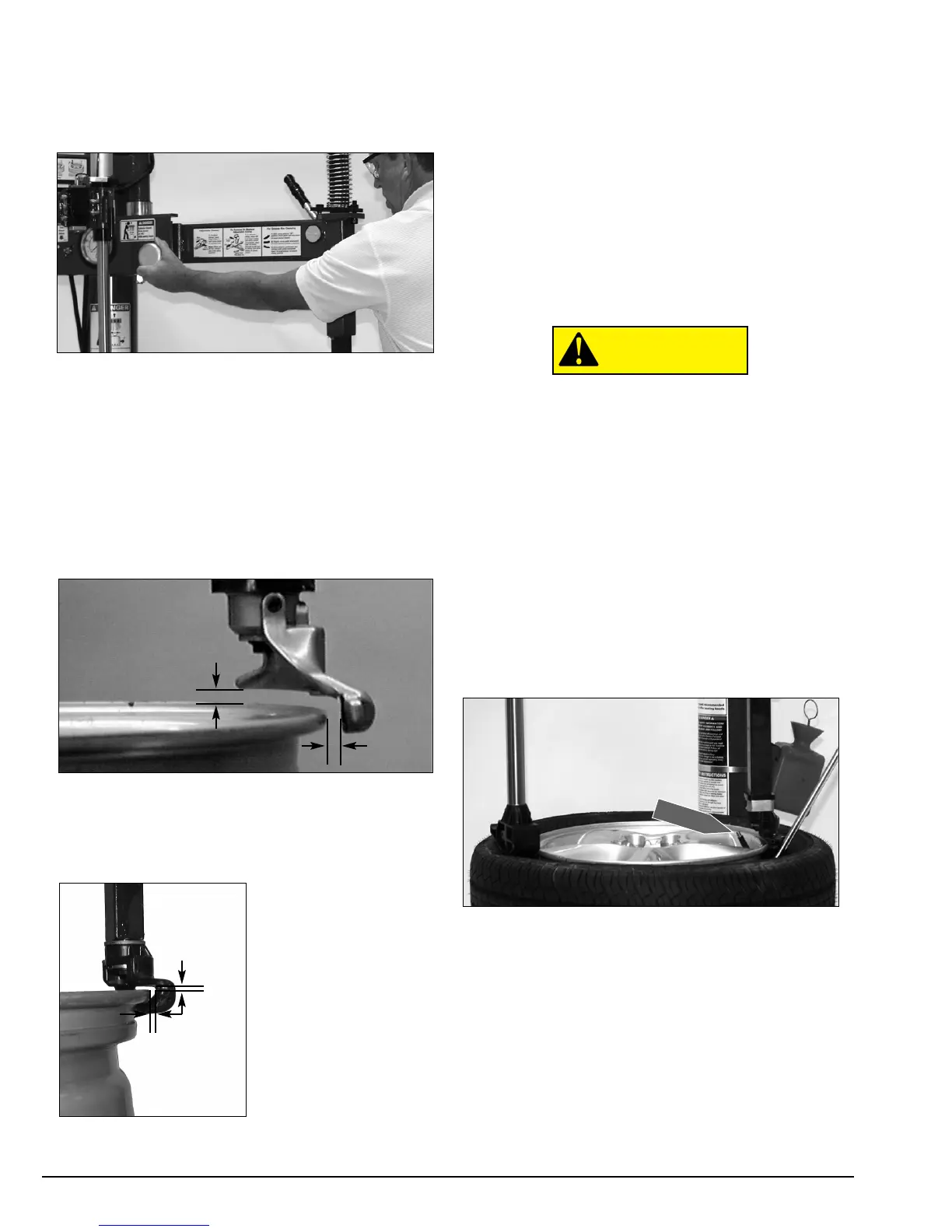

9. The mount/demount head should be in contact

with the rim edge. Turn the swing arm adjusting knob

to move the mount/demount head away from the rim

1/8 to 1/4 inch (figure 9).

Figure 9 - Adjust Swing Arm to Position Head Roller

10. Check metal head positioning. Mount/demount

metal head should be positioned with 1/8 to 3/16 inch

clearance between the top of the rim edge and the

bottom of the head, and 1/8 to 1/4 inch clearance

between the rim edge and the head roller. This clear-

ance will be maintained as long as the locking handle

and adjustment knob are not changed. The operator

may swing the arm out of the way and back into place

again without needing to reposition the head (when

changing a like set of wheels) (figure 10).

Figure 10 - Proper (Metal) Mount/Demount Head Position

11. Check plastic head positioning. Mount/demount

plastic head should be positioned with 1/16 to 1/8 inch

clearance between the top of the rim edge and the

bottom of the head, and 1/16 to 1/8 inch clearance

between the rim edge

and the inside surface of

the head. This clearance

will be maintained as long

as the locking handle and

adjustment knob are not

changed. The operator

may swing the arm out of

the way and back into

place again without need-

ing to reposition the head

(when changing a like set

of wheels) (figure 11).

Figure 11 - Proper (Plastic) Mount/Demount Head Position

H. The tool clearance may change with

machine use and should be inspected often.

Failure to maintain the proper clearance may

result in damage to the wheel rim and/or tire.

J. Normal table top rotation for demounting is

clockwise. Depress the table top pedal to

rotate this direction. To rotate the table top

counterclockwise, lift the pedal up with your

toe.

K. Table top rotation can be stopped at any

time by removing your foot from the rotation

pedal.

At times during the mounting and

demounting procedure, the bead lifting tool

may encounter resistance and can be

thrown. Keep one hand firmly on the tool to

avoid possible tool disconnect. Use the

reversing feature to back out of jam-ups. A

thrown tool can cause injury.

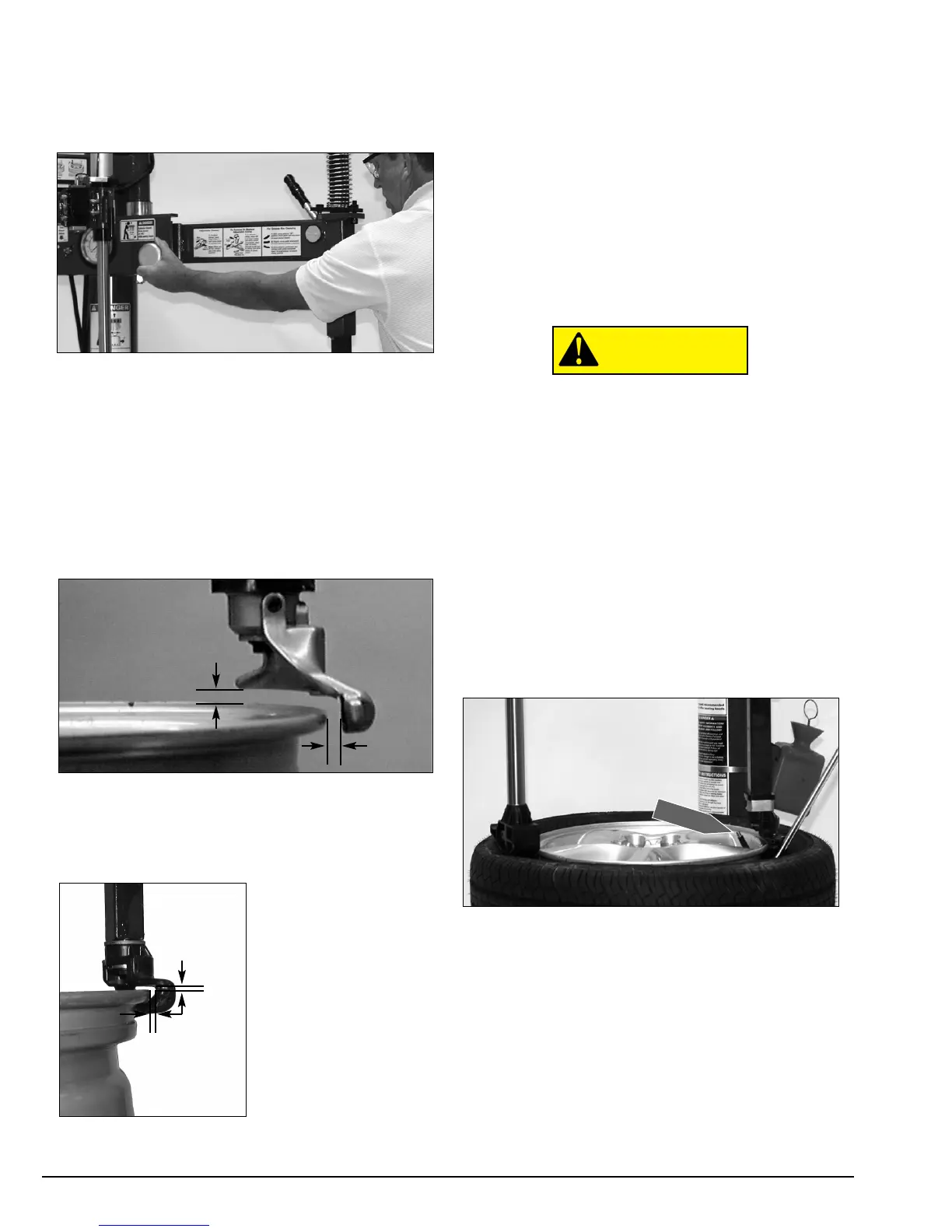

12. Insert the smooth curved end of the bead lift-

ing tool over the forward end of the demount head and

below the top bead of the tire. Lift the bead up and

over the knob on the Duckhead (figure 12). Also, note

the valve stem position to the Duckhead. Use the Robo

Arm to push down on the tire opposite the Duckhead

to allow the bead to utilize the drop center area of the

rim, this position reduces stresses in the bead and

allows an easier bead lift.

Figure 12 - Insert Bead Lifting Tool

Loading...

Loading...