15

Part 6 Gas Conversion

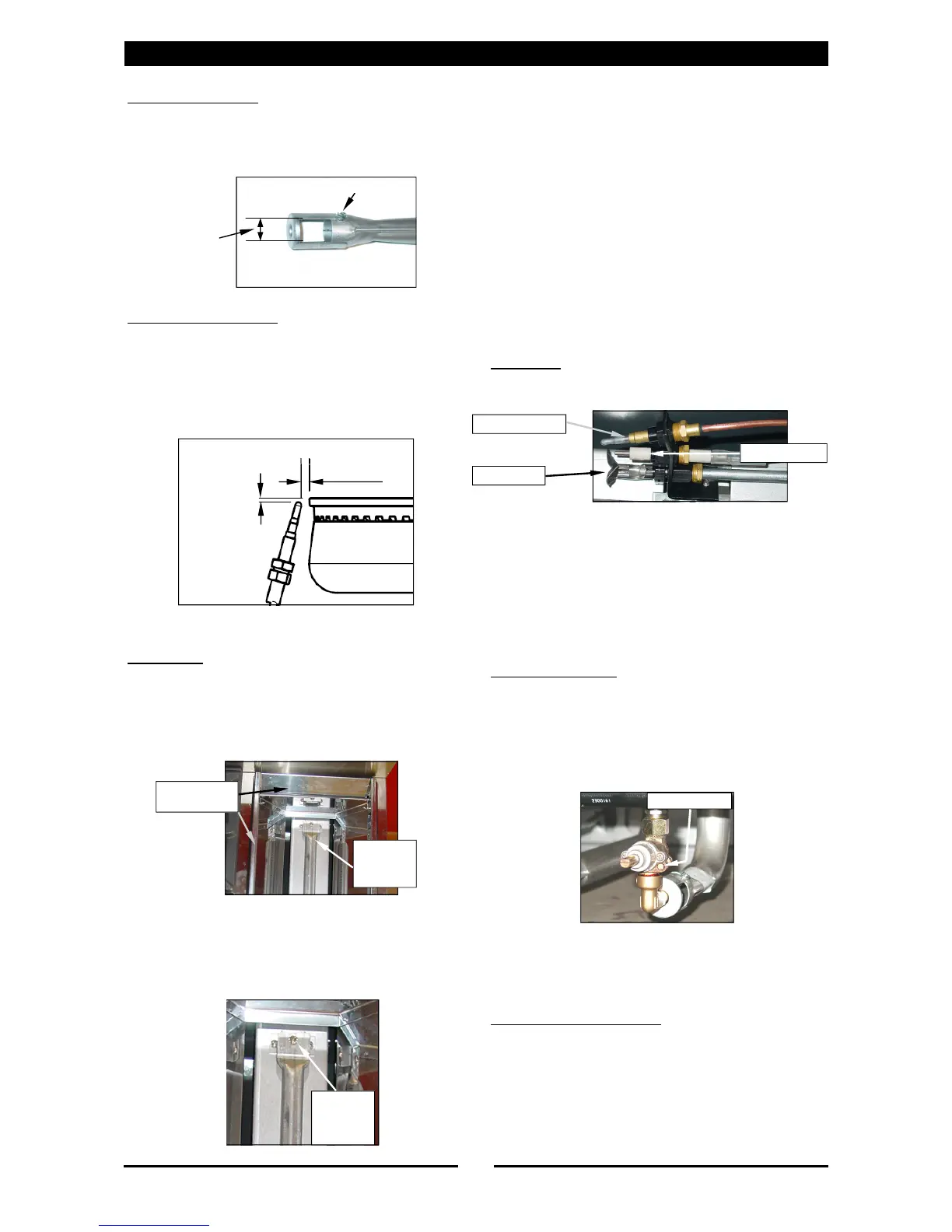

Aeration Adjustment

1. Check / adjust the main burner aeration gap.

This gap should be set to the dimensions shown

in the 'Gas Specification Tables' at the end of this

section.

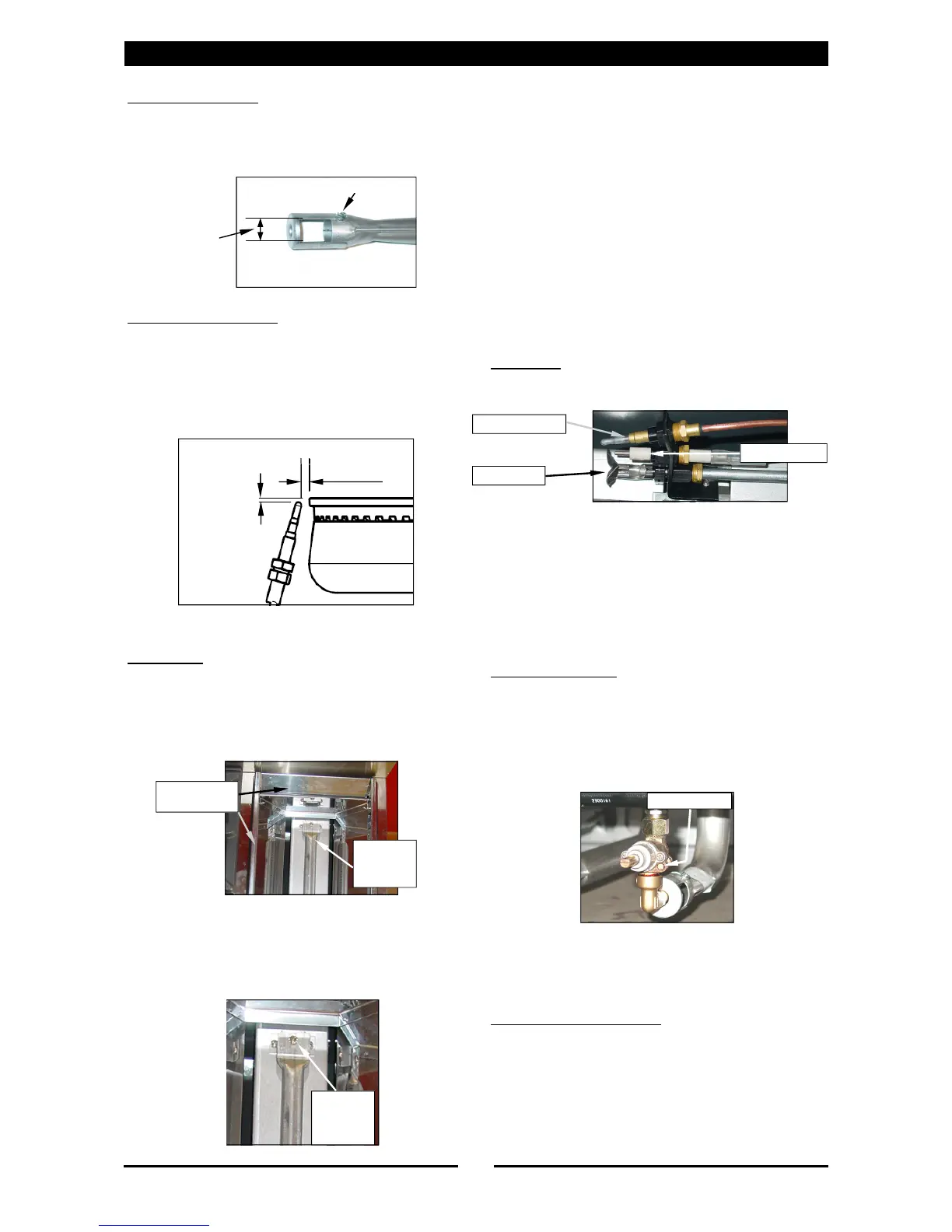

Thermocouple Location

1. Check that the thermocouple is correctly

located and that the gap between the

thermocouple and the main burner is as shown

in the diagram below.

2. Check that the thermocouple connection to the

gas valve is tight.

Griddle

Main Burner

1. With the gas supply turned off at the main

supply, remove the griddle plate section by

lifting it straight off the Cooktop.

2. Remove the gas control heat shield from around

the griddle burner, this is just a push in fit.

3. Disconnect the piezo igniter from the mounting

bracket. (For access purposes).

4. Remove the main burner from the burner box by

removing the securing screw at the end of the

burner, this will reveal the main burner injector.

5. Remove and replace the main burner injector

with correct size injector. Refer to the ‘Gas

Specifications’ table at the end of this section,

for correct injector sizes.

6. Refit the burner to the griddle burner box.

7. Refit the gas control heat shield to the griddle

burner box.

8. Refit griddle plate section to the top of Cooktop.

9. Check the thermocouple connection the gas

valve is tight.

10. Repeat Items 1 to 9 for all griddle main burners.

11. Turn ‘ON’ the gas supply at the mains, re-light

the griddle burners and check the flame size on

the ‘LOW’ flame position.

Pilot Burner

1. Disconnect the pilot supply tube from the pilot

burner.

2. Remove the existing pilot injector and replace

with the correct size for the gas being used.

Refer to the ‘Gas Specifications’ table at the

end of this section, for correct injector sizes.

3. Re-connect pilot supply tube to the pilot burner.

4. Refit the piezo igniter to the mounting bracket.

5. Repeat Items 1 to 4 for all griddle pilot burners.

Low Fire Adjustment

1. To adjust the griddle burner ‘LOW’ fire

adjustment, remove the griddle gas control

knobs from the front of the control panel.

2. Adjust the low fire adjustment screw on the

griddle gas control valve only, to obtain the

desired flame size.

NOTE:

The ‘Low Fire Adjustment Screw’ should be sealed

with coloured paint on completion of the low fire

adjustment.

Thermocouple Connection

1. Check that the thermocouple connection to the

gas valve is tight.

Low Fire Screw

Piezo Igniter

Thermocouple

Pilot Burner

Gas Control

Heat Shield

Burner

Securing

Screw

Burner

Securing

Screw

Refer to 'Gas

Specification

Tables'

Adjustment Screw

3 ±1 mm

2 ±1 mm

Loading...

Loading...