ENGINE

CONSTRUCTION - The engine is a heavy duty, 4 cylinder, valve in head,

wet

sleeve

motor with a pressure oiling

syst

em as described in detail on page 12.

A

water

pump is used with a full flow by-pass

thermostat

to insure consta

nt

motor

temperature

which is so imp

ortant

in securing long life from

the

wear

ing

parts

. All working

parts

are

protected by the

larg

e capacity oil filt

er

used,

the

heavy

duty

air

cleaner,

and

the careful sealing of the main bearings

at

the front

and

rear

of

the

crankshaft

.

The

high

quality variable speed governor provides constant engine speed control.

The main connecting rod bearings

are

of

high

precision, interchangeable, steel-

backed

babbit

design.

SERVICE -

It

is strongly recommended

that,

should

any

work have to be done on

the

motor, it be taken to your dealer. You

I'

deal

er

has

the

proper facilities and

the

trained

personnel to give your

tractor

th

e efficient

attention

that

it deserves.

16

Operating Instructions for Cockshutt "30" Tractor

•

•

•

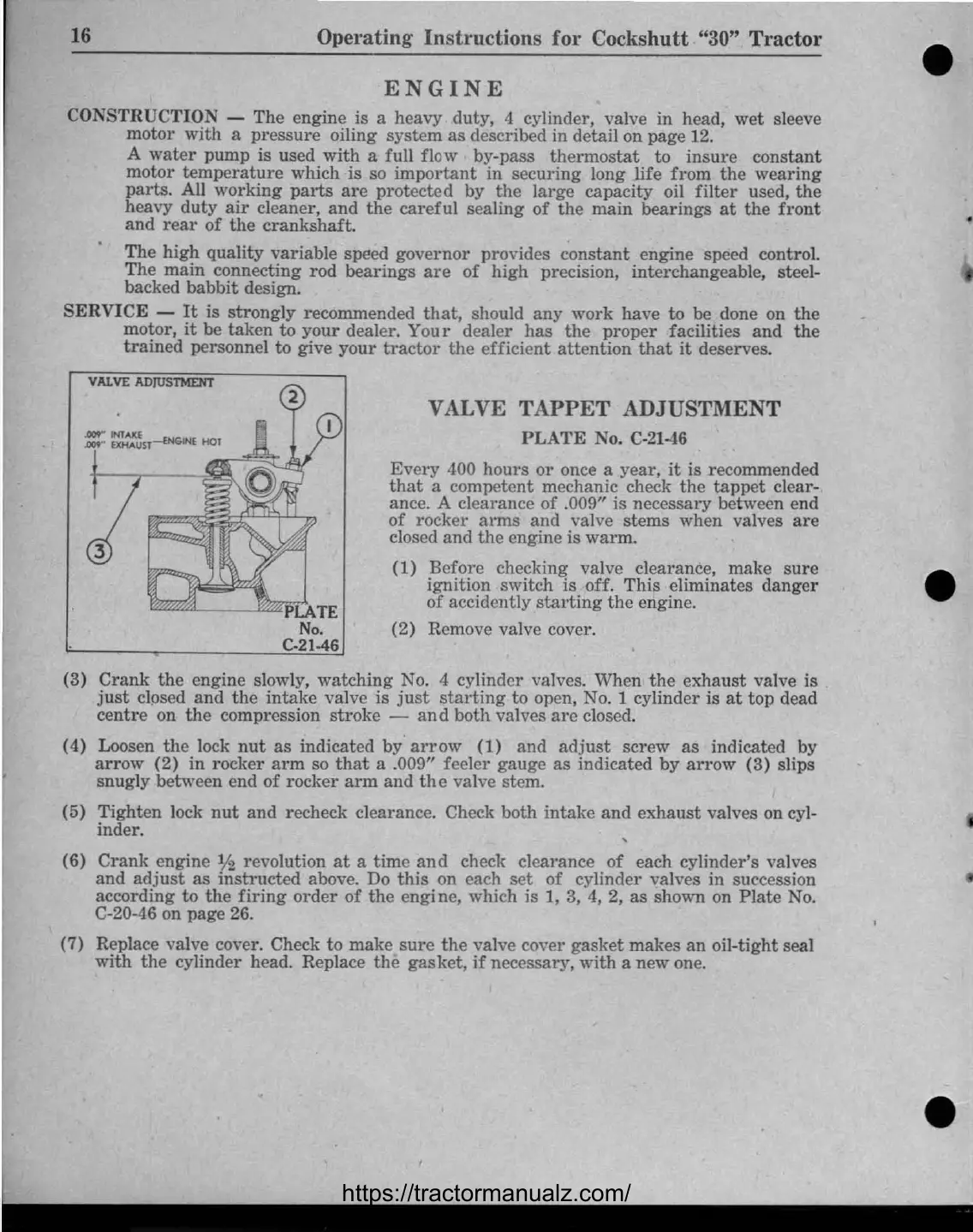

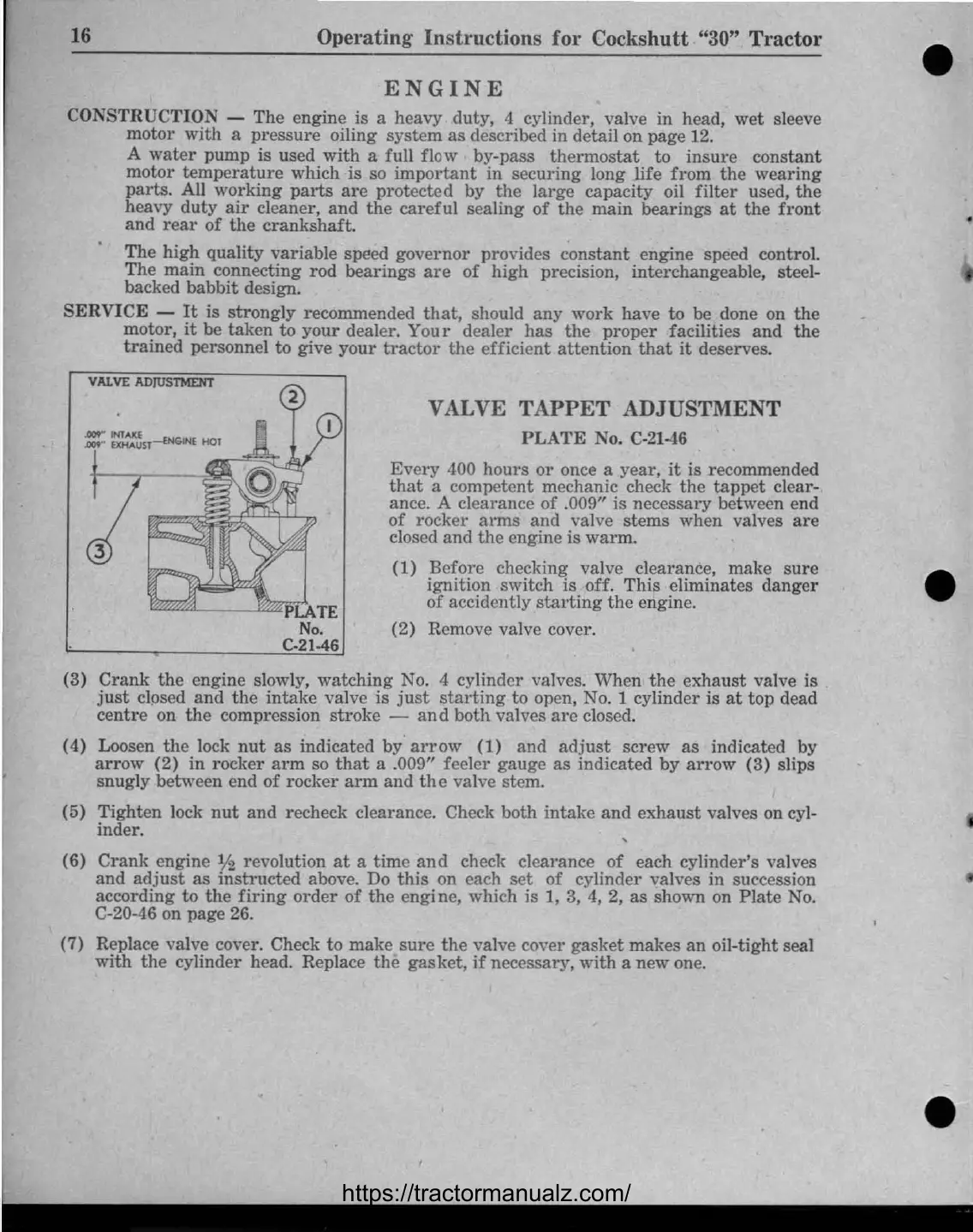

VALVE ADruSTMENT

3

[J

~~i

?£P

P

;

LA

T

E

No.

C·21

-46

VALVE

TAPPET

AD

JUS

TMENT

PLATE

No. C-21-t6

Every

400 hours

or

once a year,

it

is recommended

that

a compet

ent

mechanic check the

tappet

clear-

ance. A clearance of

.009" is necessary between end

of rock

er

arm

s and valve stems when valves

are

closed

and

the engine is warm.

(1)

Before checking valve clearance, make sure

ignition switch is off. This elimina

tes

d

ang

er

of accidently

starting

the engine.

(2) Remove valve cover.

• •

(3) Crank

the

engine slowly, watching

No.4

cylinder valves. When

the

exha

ust

valve is

just

closed and

the

intake valve is

just

starting

to open, No

.1

cyli

nder

is

at

top dead

centre on the compression stroke

-

and

both valves

are

closed.

(4) Loosen the lock n

ut

as indicated by

arrow

(1)

and

adjust

screw as indicated by

arrow

(2) in rocker

arm

so

that

a .009" feel

er

gauge as indicated by

arrow

(3) slips

snugly between end of rocker

arm

and

the

valve

st

em.

(5) Tighten lock

nut

and recheck clearance. Check both intake

and

exhaust valves on cyl-

inder.

,

(6) Crank engine

1f2

revolution

at

a

tim

e

and

check clearance of each cylind

er's

valves

and

adjust

as

instructed above. Do

this

on each set of cylinder valves in succession

according to

the

firing

order

of

the

engin

e, which is 1, 3, 4, 2, as shown on Plate No.

C-20-46 on page 26.

(7) Replace valve cover. Check to make

sure

the valve cov

er

gasket makes an oil-tight seal

with

the

cylinder head. Replace the

gasket,

if necessary,

with

a new one.

• •

https://tractormanualz.com/

Loading...

Loading...