23

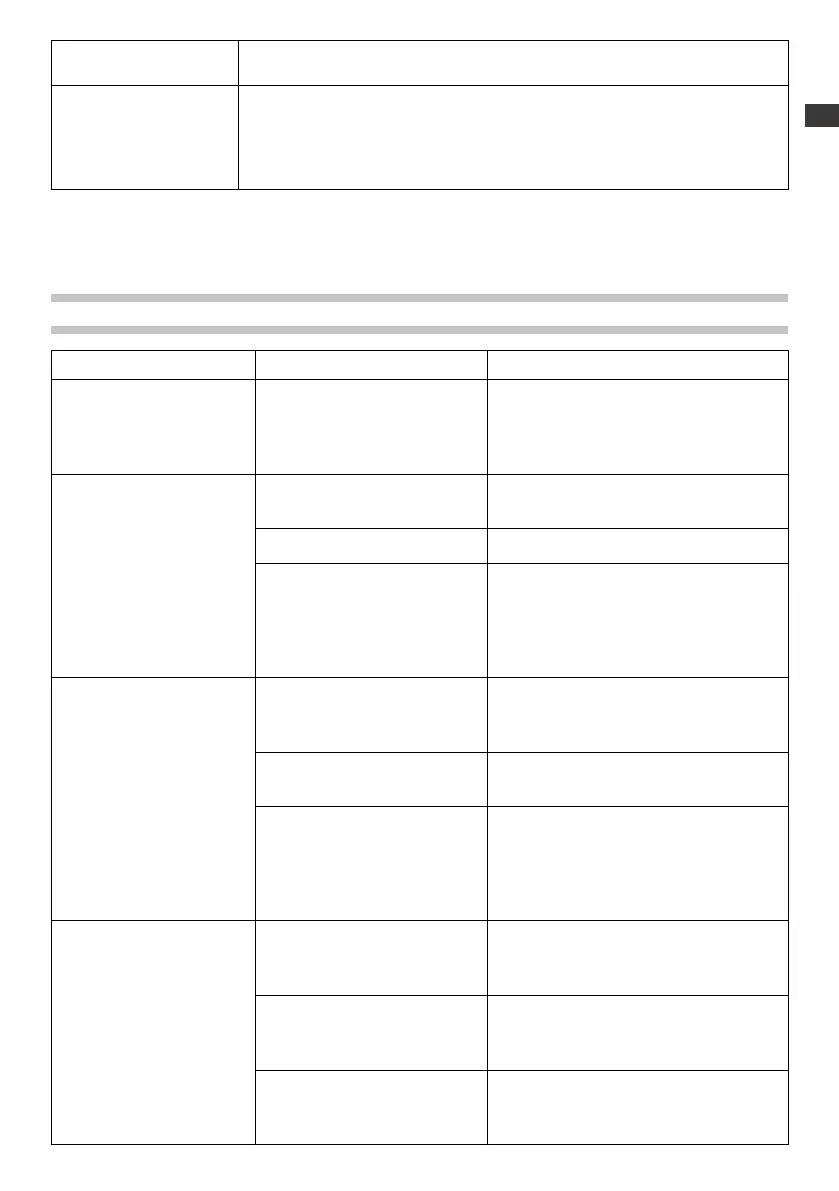

MAINTENANCE

SCHEDULE

JOB

Every 500 hours • Change pump oil and gearbox oil.

• Check the pump suction/delivery valves.

• Check tightness of pump screws.

• Check the pump regulation valve.

• Check the safety devices.

CAUTION

• The data given in the table are approximate. It might be necessary to carry out maintenance more

frequently in the case of particularly heavy work.

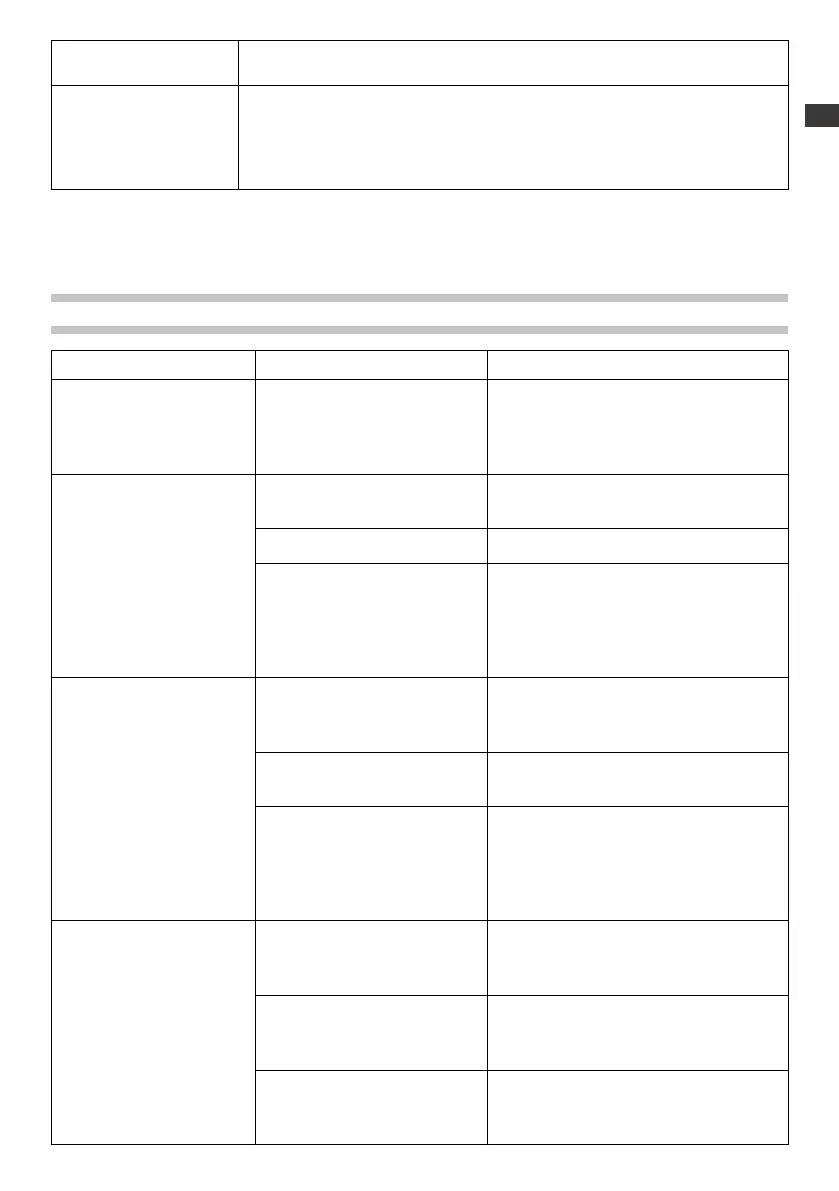

TROUBLESHOOTING

PROBLEMS CAUSES REMEDIES

The engine does not start

or there is a malfunction

with it or it stops while

working.

Refer to the engine operating

and maintenance manual.

Refer to the engine operating and

maintenance manual after having made

sure there is fuel in the tank.

The high pressure cleaner is

vibrating a lot and is noisy.

The water inlet lter(23) is dirty. Follow the instructions given in the

“ROUTINE MAINTENANCE”

paragraph.

Air suction. Check soundness of the suction circuit.

Not enough water is being

supplied or priming depth is

excessive.

Make sure the tap is fully open and that

the mains flow rate or priming depth

conform to what is specified in the

“SPECIFICATIONS AND TECHNICAL

DATA”

paragraph.

The high pressure cleaner

fails to reach maximum

pressure.

The regulation valve is set

for a pressure lower than the

maximum one.

Turn the pressure regulating knob (17)

clockwise.

The nozzle is worn. Replace the nozzle as explained in the

“ROUTINE MAINTENANCE”

paragraph.

Not enough water is being

supplied or priming depth is

excessive.

Make sure the tap is fully open and that

the mains flow rate or priming depth

conform to what is specified in the

“SPECIFICATIONS AND TECHNICAL

DATA”

paragraph.

No water coming through

the nozzle.

No water. Check that the mains water tap is fully

open or that the suction hose is able to

prime.

Suction depth is excessive Make sure priming depth conforms to

what is specied in the

“SPECIFICATIONS

AND TECHNICAL DATA”

paragraph.

Water nozzle clogged. Clean and/or replace the nozzle

as explained in the

“ROUTINE

MAINTENANCE”

paragraph.

EN

Loading...

Loading...