32

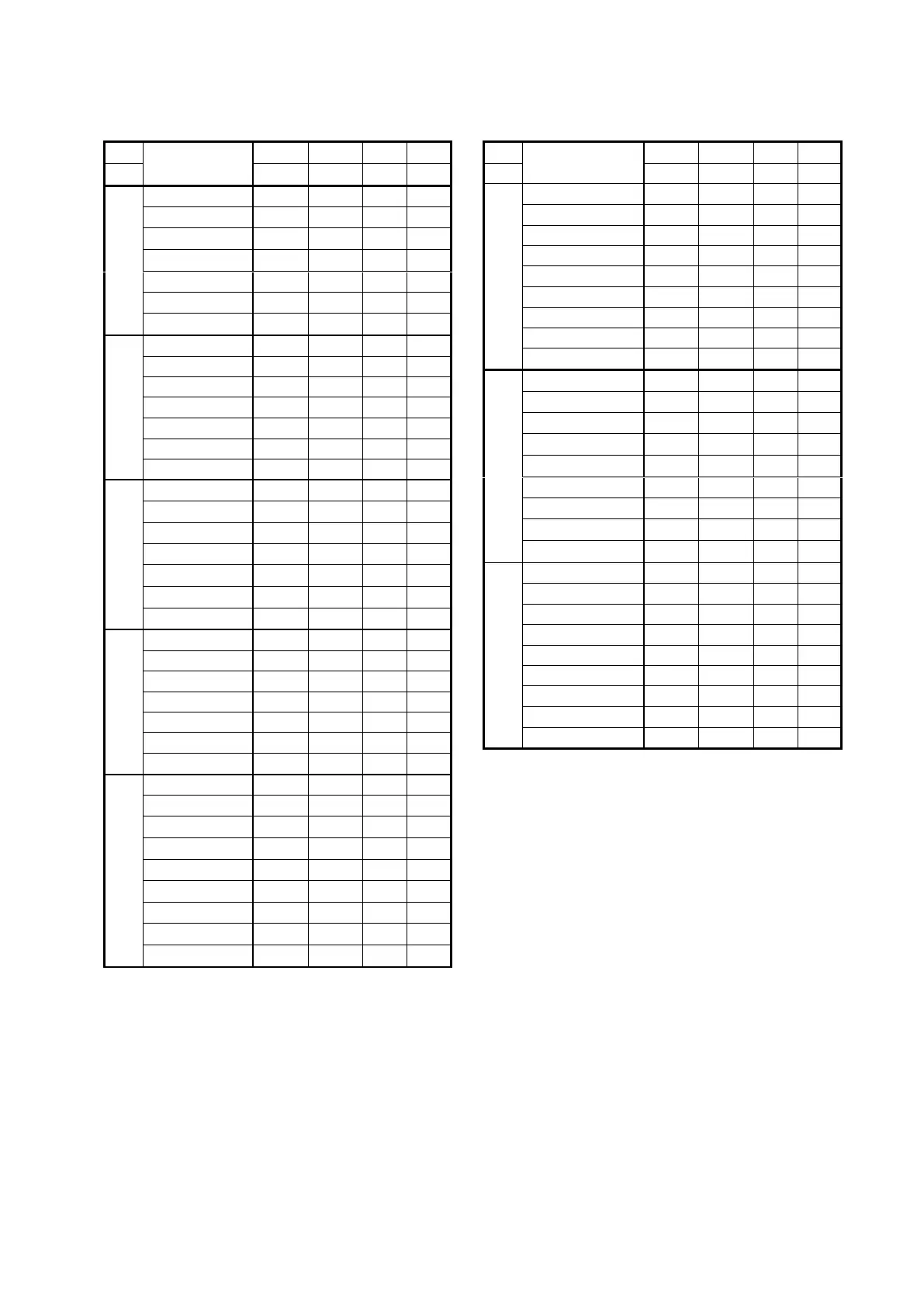

Table 3b. Dimensions of the connections of CGT-02 turbine meters (DN50÷DN400).

Impurities inside a pipeline system carried by gas may cause mechanical damage to the gas

meter or at least reduce its measurement accuracy. Therefore, a filter with efficacy not worse

than 10 m should be installed upstream the gas meter (particularly when the flowing gas

contains high amounts of impurities). In addition, the inflow side of the system should be

thoroughly cleaned before installing the gas meter. Conical sack filter may be placed

on the inlet of the inflow section; the filter should be removed after 1 2 months of operation.

If the filter is not removed, monitoring of the filter impurity level should be provided

by means of pressure drop measurements or regular check-ups. If clogged, the sack filter may

be destroyed by the gas pressure, and filter debris may seriously damage the gas meter.

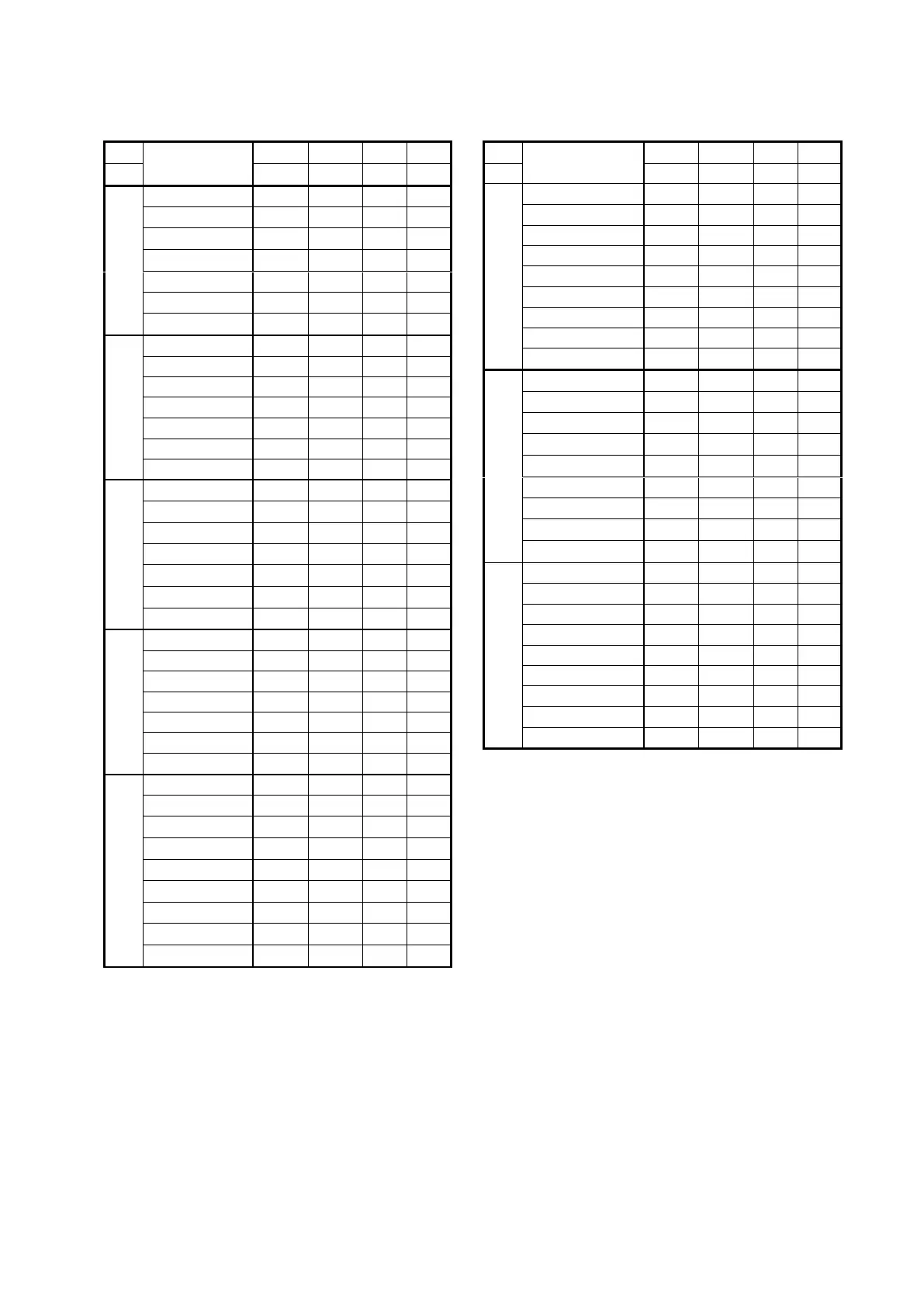

Table 3b. Basic dimensions and weights of CGT-02 turbine gas meters in the DN400÷DN600

size range

Table 3b. Basic dimensions and weights of CGT-02 turbine gas meters in the DN400÷DN600

size range

Loading...

Loading...