4.2 Audio/Visual Display

000

N

Hz

lbs

000

N

Hz

lbs

000

N

Hz

lbs

Visual Measurement Results

Tension displayed in newtons.

Frequency mode, results displayed

as hertz (cycles/sec).

Tension displayed in pounds-force.

A dark oval will appear to indicate the units

associated with the number displayed.

Audible Signals

Signal When Means

One beep Upon release of SPAN key Input accepted

Upon release of MASS key Input accepted

While sensor is aimed at vibrating belt Measurement taken

Two beeps Upon pushing MEM key after releasing SPAN key Span data has been stored

Upon pushing MEM key after releasing MASS key Mass data has been stored

Four beeps Combined with “000” newton display Newton result is out of range

Combined with “000” pound display Pound result is out of range

After pushing ON key and combined with “zero” countdown Low battery condition

The TensionRite® Belt Frequency Meter is an interactive tool. It

provides both visual and audible communication with the operator.

Each signal or combination of signals has meaning. While all these

signals are discussed in other sections of this manual, here will be

presented a compilation of all the available signals.

Generally visual signals alone give measurement results while

audible signals, either alone or in combination with a visual signal,

indicate some operational step.

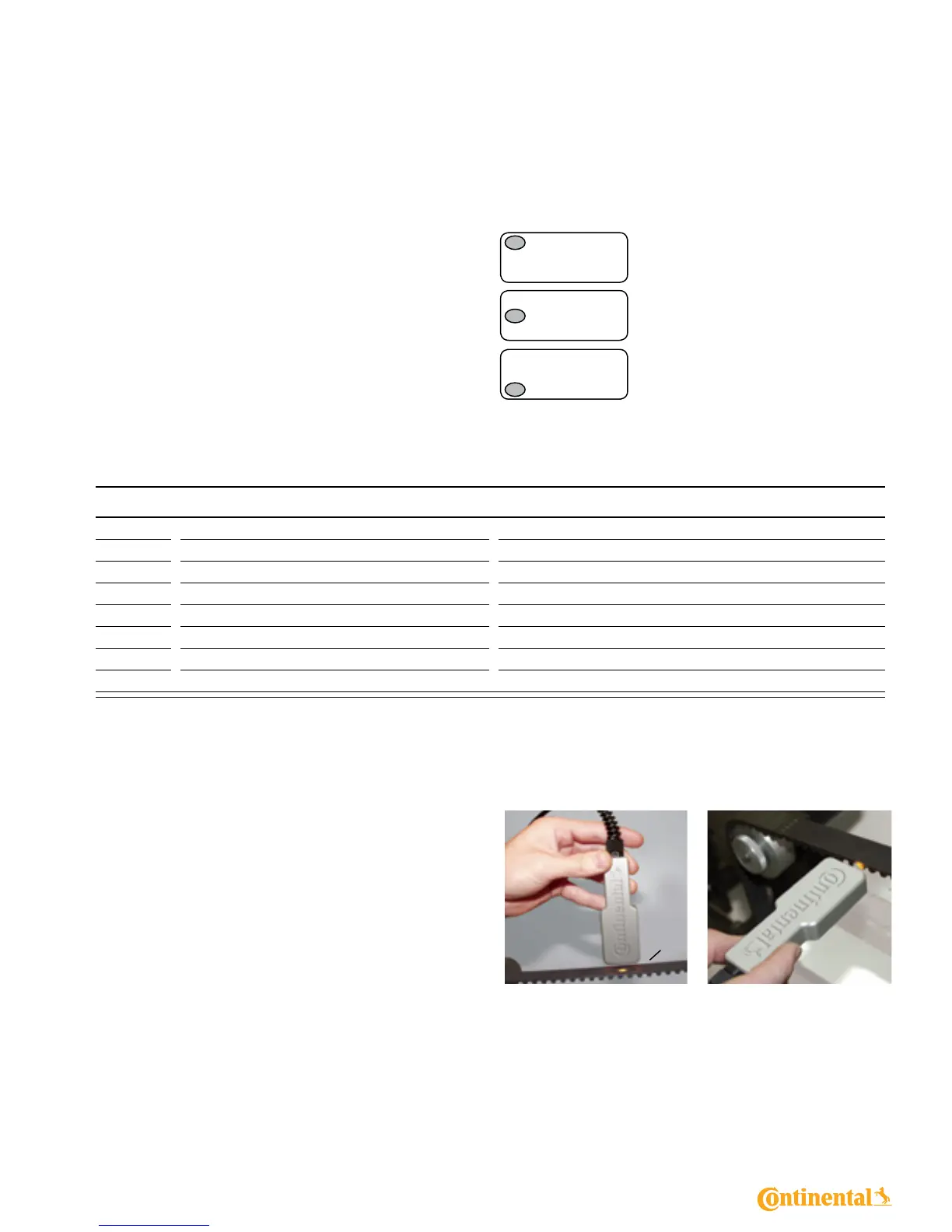

Gap

3/8 in.

to 2 in.

4.3 Optical Sensor

The sensor uses an invisible infrared beam to detect vibrations of

the belt. A narrow angle orange LED-generated beam is provided

to guide the aiming of the sensor.

The very best signal from the belt is seen when the sensor is held

perpendicular to the belt at the center of the span and at a 3/8 in.

(9.5mm) distance. It is also a good practice to orient the long edge

of the sensor head parallel to the centerline of the belt. This helps

reduce the eect of any divergence between the aiming beam and

the infrared sensing beam.

When physical restrictions are present, it is possible to get usable

readings with the sensor at up to 2 in. distance from the belt and/

or tipped up to 45 degrees from perpendicular.

It is possible to take measurements from the edge of the belt.

The toothed side of a belt is equally acceptable as a target for

the sensor.

The sensor LEDs should be kept clean by wiping with a soft

cotton cloth. Solvents are never to be used.

Power Transmission Products 4.0 Functions

7

Loading...

Loading...