Guide pas à pas pour l’Unidrive M100/M101/M200/M201/M300 11

Édition : 1

English Français Deutsch Italiano Español

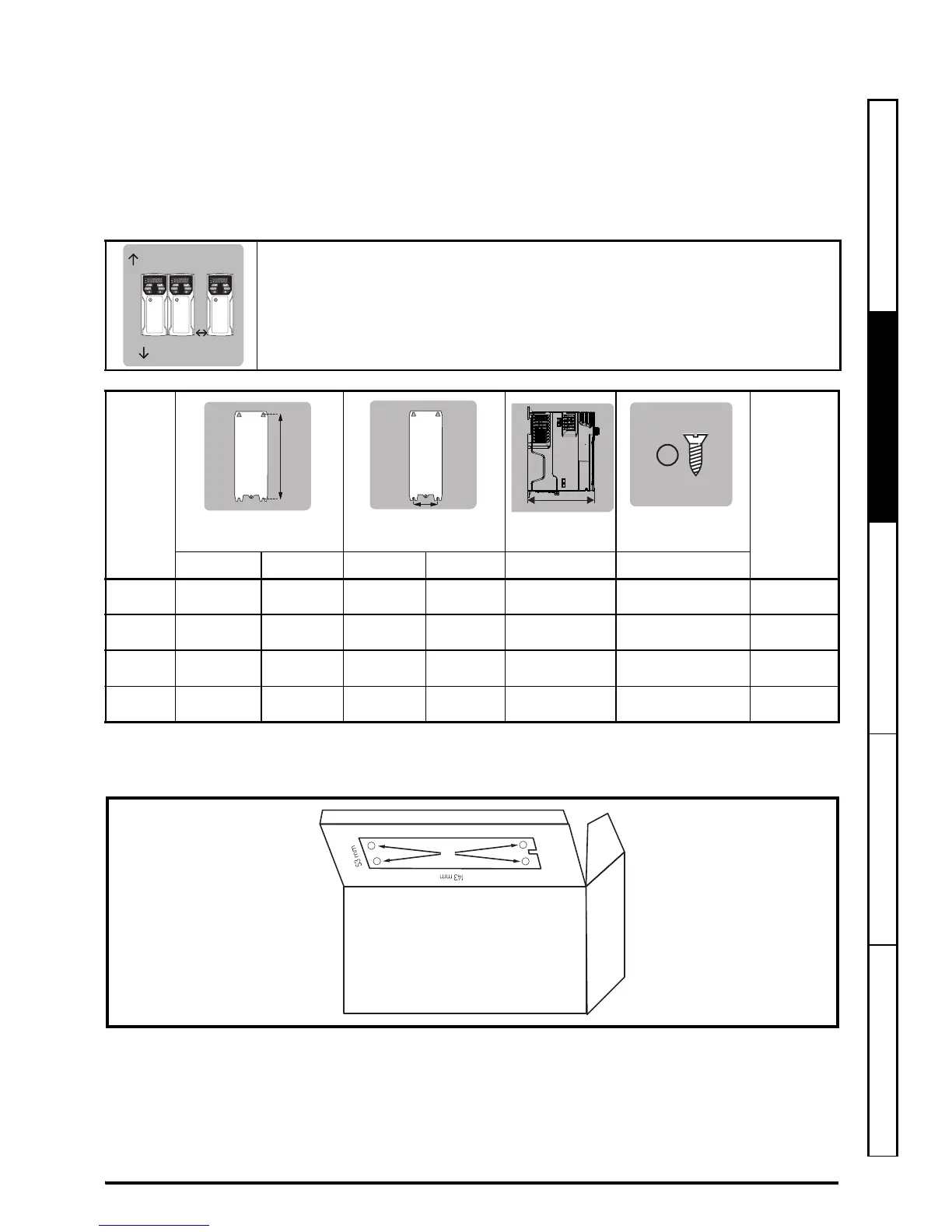

ÉTAPE 3 : Montage du variateur

Plage de température ambiante en fonctionnement :

- 20 à 60 °C

Un déclassement du courant de sortie peut être nécessaire pour des températures ambiantes >40 °C.

Consulter le Guide d’installation - Puissance (section 5.1). Pour les installations UL, la température ambiante

maximale autorisée est de 50 °C, quel que soit le déclassement appliqué.

Les variateurs peuvent être montés sans espacement entre eux. Prévoir un espacement minimum de 100 mm

au-dessus et au-dessous du variateur. Pour des informations concernant le déclassement applicable pour des

espacements inférieurs, se reporter à la section 3.4 du Guide d'installation - Puissance.

* Le Potentiomètre de référence de vitesse ajoute 11 mm supplémentaires à la profondeur totale pour les

variateurs Unidrive M101 et M201 uniquement.

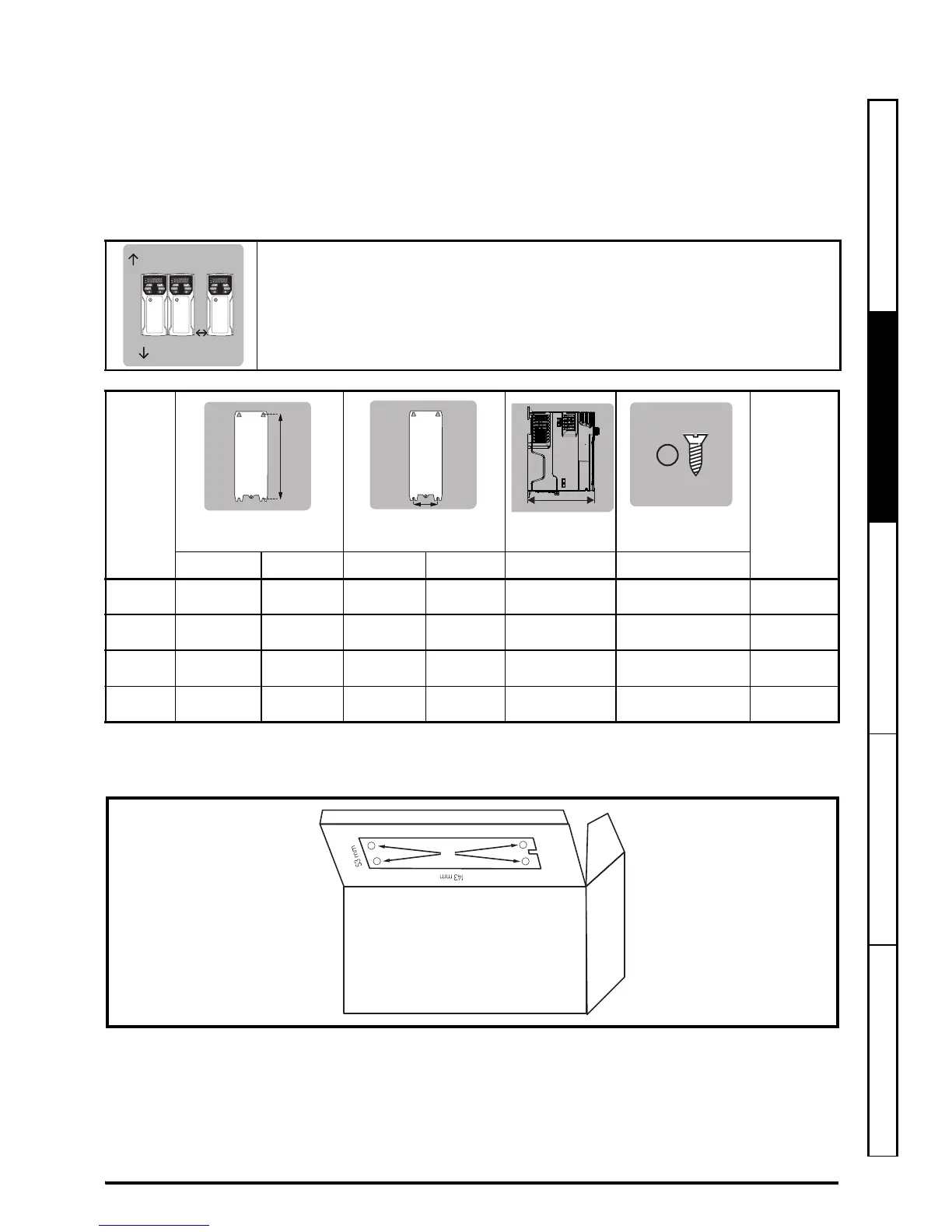

Un gabarit de perçage pour le montage mural est fourni avec le variateur (voir l’illustration ci-dessous).

ÉTAPE 4 : Montage de l’étrier de mise à la terre

L’étrier de mise à la terre facilite la gestion des câbles après leur connexion au variateur. L’étrier est aussi utilisé

pour fixer le blindage des câbles à la terre afin de permettre la conformité CEM (voir la Figure 7-1).

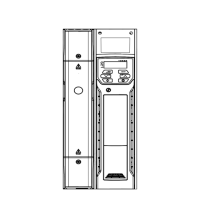

Taille

Poids

HLP*Ø

Fixation Hors tout Fixation Hors tout Hors tout Diamètre

1 143 mm 160 mm 53 mm 75 mm 130 mm 5 mm 0,75 kg

2 194 mm 205 mm 55 mm 75 mm 150 mm 5 mm 1,3 kg

3 215 mm 226 mm 70,7 mm 90 mm 160 mm 5 mm 1,5 kg

4 265 mm 277 mm 86 mm 115mm 175mm 6mm 3,13kg

Loading...

Loading...