Installing the Recloser and Control

All reclosers are carefully tested and adjusted at the fac-

tory to operate according to published data. Well

equipped test facilities, detailed testing procedures, and

thoroughly trained personnel assure accurately calibrat-

ed equipment. Each recloser leaves the factory ready for

installation. Pre-installation testing is not necessary.

Use the following procedure when installing the recloser.

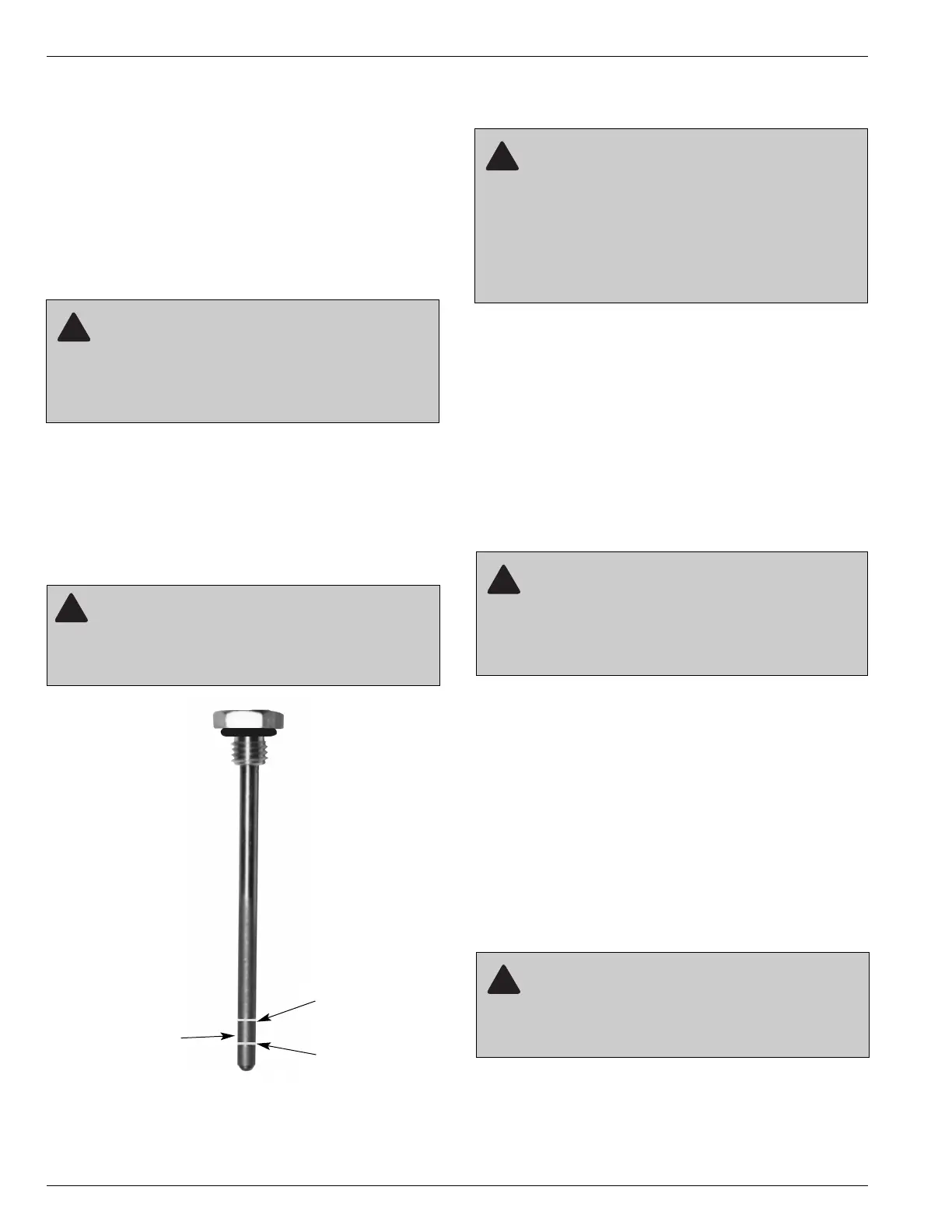

1. Check the oil level. Using the dipstick provided on

the recloser head, make sure the oil in the recloser

tank is at the proper level (Figure 8). Measure the oil

level with the dipstick completely screwed in at 25°C.

If the oil is below the minimum level, fill the recloser

with oil to the proper level, using the dipstick opening.

Do not exceed the maximum oil level, as indicated by

Figure 8.

2. Test the oil dielectric strength. If the recloser has

been stored for some time or is being relocated, per-

form a dielectric test on the oil in accordance with

ASTM-approved testing procedures.

A. On new equipment, the oil must have minimum

dielectric strength of 26 kV.

B. If the dielectric strength of the oil is less than 26 kV,

filter the oil to restore its dielectric strength to

acceptable minimum level.

3. Check the data plate ratings. Be sure the ratings

on the recloser data plates are correct for the instal-

lation.

4. Perform high-potential withstand tests. Prior to

installing the recloser, perform high-potential with-

stand tests. Refer to the Testing section of this man-

ual for high-potential withstand test procedures.

5. Program and Install the control. All VXE electronic

controls are carefully tested at the factory and

shipped with plug-in TCC cards connected and ready

for operation. Before installation, inspect the control

and make sure that all TCC components are correct

for the planned installation. Connect the control bat-

tery to the battery plug as shown in Figure 4. Make

sure that all DIP switch settings are set correctly and

that the control cable is connected between the

recloser and control.

6. Mount the recloser. Use the lifting lug located on the

head casting and follow approved procedures.

Note: It is important that the recloser be mounted on the

level to accurately check the oil.

Type VXE Single-Phase Electronically Controlled Recloser Installation and Operation Instructions

12

INSTALLATION PROCEDURE

CAUTION: This equipment relies on oil to pro-

vide electrical insulation between components.

The dielectric strength of the oil must be checked on a

regular basis, as part of the routine maintenance

inspection, to ensure that it is at or above minimum

dielectric requirements. Use of this equipment with

insulating oil that does not meet minimum require-

ments can result in internal flashovers that will damage

the equipment and can cause personal injury. G107.2

Loading...

Loading...