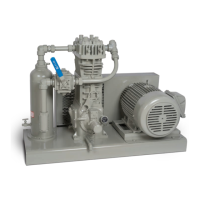

Model 491-107

Installation, Operation

& Maintenance Manual

Plain Style Compressors for Liquid

Transfer-Vapor Recovery

Solutions beyond products...

ORIGINAL INSTRUCTIONS IE101K

Warning: (1) Periodic inspection and maintenance of Corken products is essential. (2) Inspection, maintenance and installation of

Corken products must be made only by experienced, trained and qualified personnel. (3) Maintenance, use and installation of Corken

products must comply with Corken instructions, applicable laws and safety standards. (4) Transfer of toxic, dangerous, flammable or

explosive substances using Corken products is at user’s risk and equipment should be operated only by qualified personnel according

to applicable laws and safety standards.