STANDARD RECOMMENDED PROCEDURE 003-722 | ISSUE 4 | OCTOBER 2015 | PAGE 6 OF 10

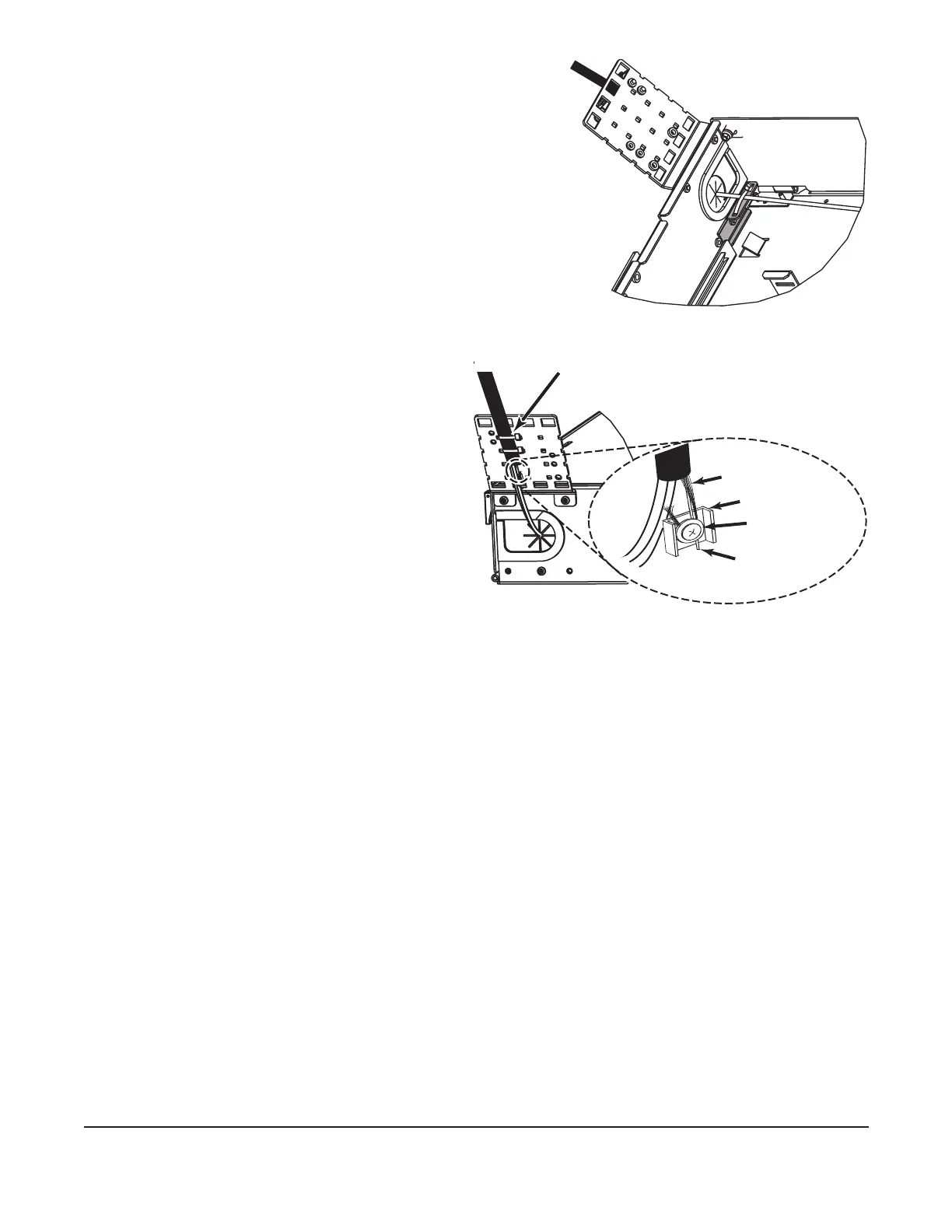

Step 2: Follow installation instructions provided

with the UCC kit to secure the cable.

Do not tighten yet to allow for cable

adjustment if necessary.

Step 3: Secure cable to cable entry plate using

a loose cable tie (Figure 7). Do not

overtighten cable tie.

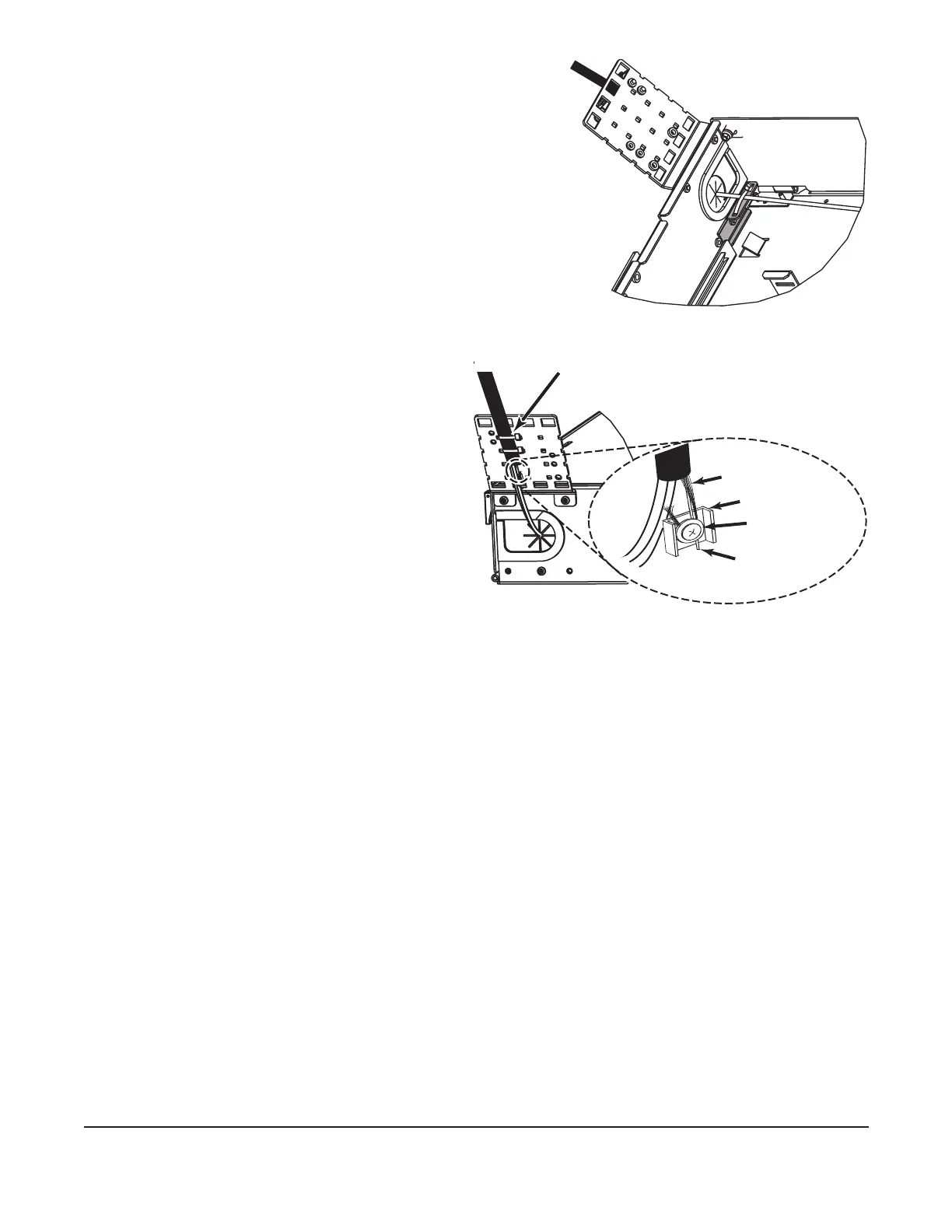

4.4.2 Using Cable Ties

Step 1: Attach the cable tie to the strain-relief

bracket in two places as shown in

Figure 8.

Step 2: Allow room on the bracket to

strain-relieve the cable strength

member, if present.

Step 3: Secure cable to cable entry

plate using a loose cable tie

(Figure 8). Do not overtighten

cable tie.

Figure 8

4.4.3 Strain-relieving the Cable Central Member

Step 1: Install the U-shaped washer and the at washer on the strain-relief bracket in the

orientation shown in Figure 8 using the supplied Phillips machine screw.

Step 2: Place the central member and yarn, if present, between the U-shaped washer and

the at washer.

Step 3: Wrap yarn around the screw in a clockwise direction and under the U-shaped

washer.

Step 4: Tighten the screw.

Step 5: Trim off the excess yarn and central member.

4.4.4 Grounding Armored Cable

One grounding kit (p/n FDC-CABLE-GRND, purchased separately) is required to ground each

armored cable. Follow instructions provided with the grounding kit.

Step 2: Attach the other end of the ground wire to the equipment rack. The equipment rack

must be grounded to the primary building ground.

Step 3: Remove the paint from the frame at the grounding location to ensure metal-to-

metal contact. It is recommended to use an antioxidant on the bare metal to prevent

corrosion.

Step 4: Or, attach the other end of the ground wire to a rack-mounted grounding bus bar,

which is grounded to the primary building ground.

KPA-0152

Figure 7

Cable ties

Yarn (if present)

Y-shaped washer

Flat washer

Central member

Loading...

Loading...