LARGE SCALE

Very large-scale applications can include bridges, trucks, or planes that are 10’s or 100’s of meters in size. Using a very large

stencil, like one made from a vinyl sheet using water or laser cutting, can work well. The dots will be so large that you can

simply roll paint over the stencil (using rollers that are used to paint walls).

HIGH TEMPERATURE

Standard paints and inks may crack or otherwise change when used for high temperature tests, making them not suitable.

Any change in the pattern that occurs after the reference image has been taken will misrepresent actual strains. There are

spray paints available at most local hardware stores that are designed for conditions up to 1200 degrees F. Enamel paints

are available for use up to 2000 degrees F. Some inks are also designed for use in high temperature applications. The

Industrial Sharpie Pro is rated for 500 degrees F.

Toner is generally not acceptable for high heat use due to it melting, but carbon black and graphite particles are as they can

withstand high temperature.

The presence of heatwaves may complicate the use of DIC. It is important to take action to minimize this in the test setup

but using larger dots can help improve results when this occurs.

THIN/MEMBRANOUS SPECIMEN

For very thin or membranous specimen, common methods for applying a speckle pattern may significantly change the

properties of the specimen. For example, applying a base coat of paint may stiffen the material. It is recommended that ink

is use and that if necessary, not base coat is applied.

HIGH STRAIN

The difficulty with high strain tests is often the original speckle pattern gets destroyed during the test. Spray paint, once

dry, will become brittle and be destroyed in high strain. For high strain applications (more than 15-20%), primer spray paint

might be desirable for the base coat. For example, Rust-oleum Clean Metal Primer holds 40% strain before it cures.

However, after about an hour, the primer will cure and become brittle.

For strains higher than 40%, it is sometimes best to use no base coat and ink based speckles (stamps or permanent marker),

so that the pattern does not crack and deteriorate. Most of the time strains this high are polymers, which tend to be light in

color and non-reflective so luckily a base coat may not be required. If the specimen material is clear, you may backlight it

(more on this under Backlighting).

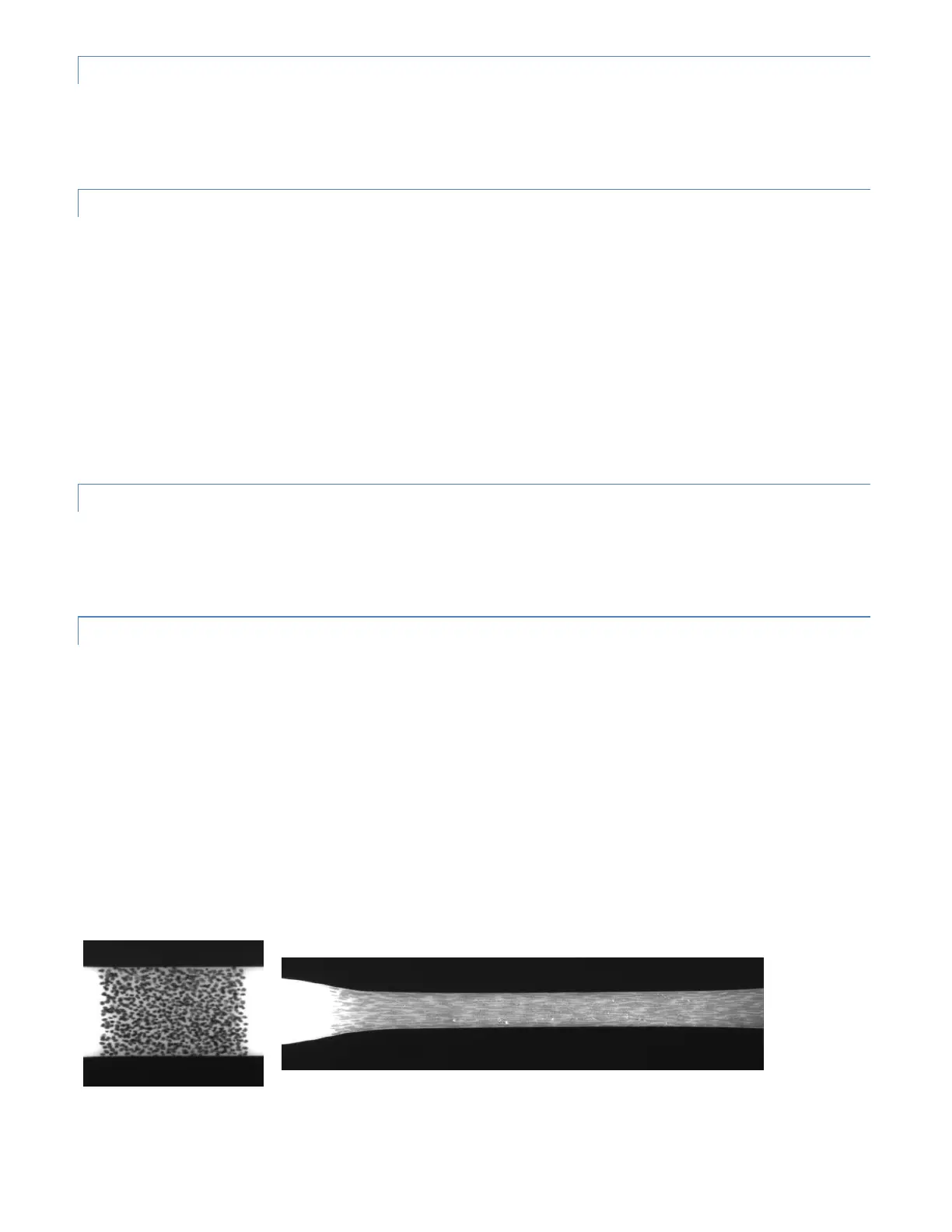

The pattern below was placed on a ½” (12mm) wide dog-bone of HDPE. The specimen is displayed before and after

deformation; the correlation was successful at strains up to 400%.

Loading...

Loading...