1 1

Operator’s Manual

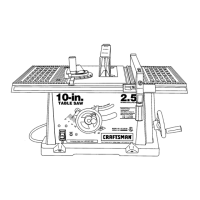

10 IN. TABLE SAW WITH LEG SET

Model No. 137.218073

Customer Help Line

For Technical Support

1-800-843-1682

Sear

s Parts &

Repair Center

1-888-331-4569

Sears Brands Management Corporation Hoffman Estates, IL 60179 USA

See the full line of Craftsman

®

products at craftsman.com

Click on the Craftsman Club

®

link and join today!

Part No. 137218073001 Printed in Taiwan

CAUTION:

Before using this Table Saw,

read this manual and follow

all its Safety Rules and

Operating Instructions

●

Safety Instructions

●

Assembly

●

Operation

●

Maintenance

●

Parts List