Do you have a question about the Craftsman 315.220100 and is the answer not in the manual?

Guidelines for selecting and using appropriate extension cords.

Proper grounding procedures to reduce electrical shock risk.

How to connect the saw to a power supply.

Steps to convert the saw's voltage from 120V to 240V.

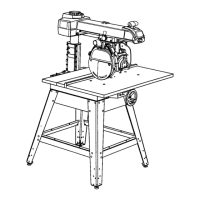

Step-by-step instructions for assembling the saw's leg stand.

Securing the saw unit to the assembled leg stand.

Installing the handwheel for adjusting saw arm height.

Mounting the yoke assembly onto the carriage.

Procedure for safely removing the saw blade and guard.

Installing the supports for the saw's table sections.

Adjusting the arm lock knob for proper arm angle control.

Adjusting the bevel lock lever for blade angle security.

Adjusting the inner column tube for snug fit and smooth operation.

Adjusting carriage bearings for blade stability and cut accuracy.

Ensuring the table supports are perfectly level for accurate cuts.

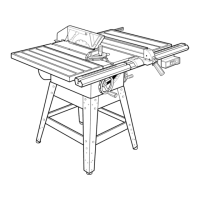

Installing the fixed front section of the saw's worktable.

Reinstalling the saw blade and ensuring the blade guard functions correctly.

Centering the riving knife with the blade to prevent binding and kickback.

Attaching indicators to show distance from blade to rip fence.

Ensuring the arm is at 0° for accurate cross cut travel.

Squaring the blade to the table at a vertical 0° bevel for accuracy.

Aligning the blade's miter angle to the fence to prevent binding.

Squaring the blade to the table at 90° bevel for accurate horizontal cuts.

Adjusting rip scale indicators for accurate fence-to-blade measurements.

Connecting the control cut device for enhanced operator control.

Using a laser for quick, routine checks of saw alignment.

Overview of different types of cuts possible with the radial arm saw.

Explains common causes of kickback for safety.

Provides essential safety tips to prevent kickback injuries.

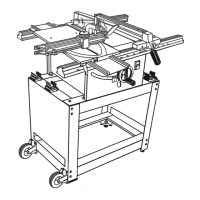

Discusses tools like pushsticks, pushblocks, and featherboards for safer cuts.

Step-by-step guide for performing a standard cross cut.

Instructions for making angled cross cuts using the radial arm.

Guide for making cuts with the blade angled relative to the table.

How to perform cuts with both arm and blade angles set.

Specific safety warnings and precautions for rip cutting operations.

Procedures for properly setting up the saw for rip cuts.

Step-by-step guide for performing a rip cut safely.

How to safely cut long pieces of material.

Instructions for performing cuts that do not go through the material.

Steps for attaching the laser guide to the saw blade.

How to use the laser guide for alignment and cutting.

Instructions for replacing batteries in the laser guide.

Routine cleaning, checks, and care for the saw.

Maintenance specific to the motor and electrical components.

Solutions for when the saw fails to power on.

Troubleshooting low motor speed or power issues.

Solutions for motor stalling or circuit interruptions.

Diagnosing and fixing motor overheating problems.

Addressing excessive vibration during saw operation.

Troubleshooting causes of unusual noise from the running saw.

Resolving issues with smooth carriage movement.

Diagnosing and fixing causes of saw stalling during rip cuts.

Solutions for a stiff handwheel or binding column.

Addressing wood burning or scoring during cuts.

Troubleshooting inaccurate bevel cuts.

Fixing inaccurate miter or cross cuts.

Resolving issues where wood pulls away from the fence during ripping.

Fixing inconsistent depth of cut.

Addressing the riving knife hitting the workpiece.

Solutions for wood being pushed sideways during cross cuts.

| Model Number | 315.220100 |

|---|---|

| Type | Circular Saw |

| Blade Diameter | 7-1/4 inches |

| No Load Speed | 5000 RPM |

| Arbor Size | 5/8 inch |

| Depth of Cut at 45 degrees | 1-3/4 inch |

Loading...

Loading...