Page 37

Troubleshooting Procedures

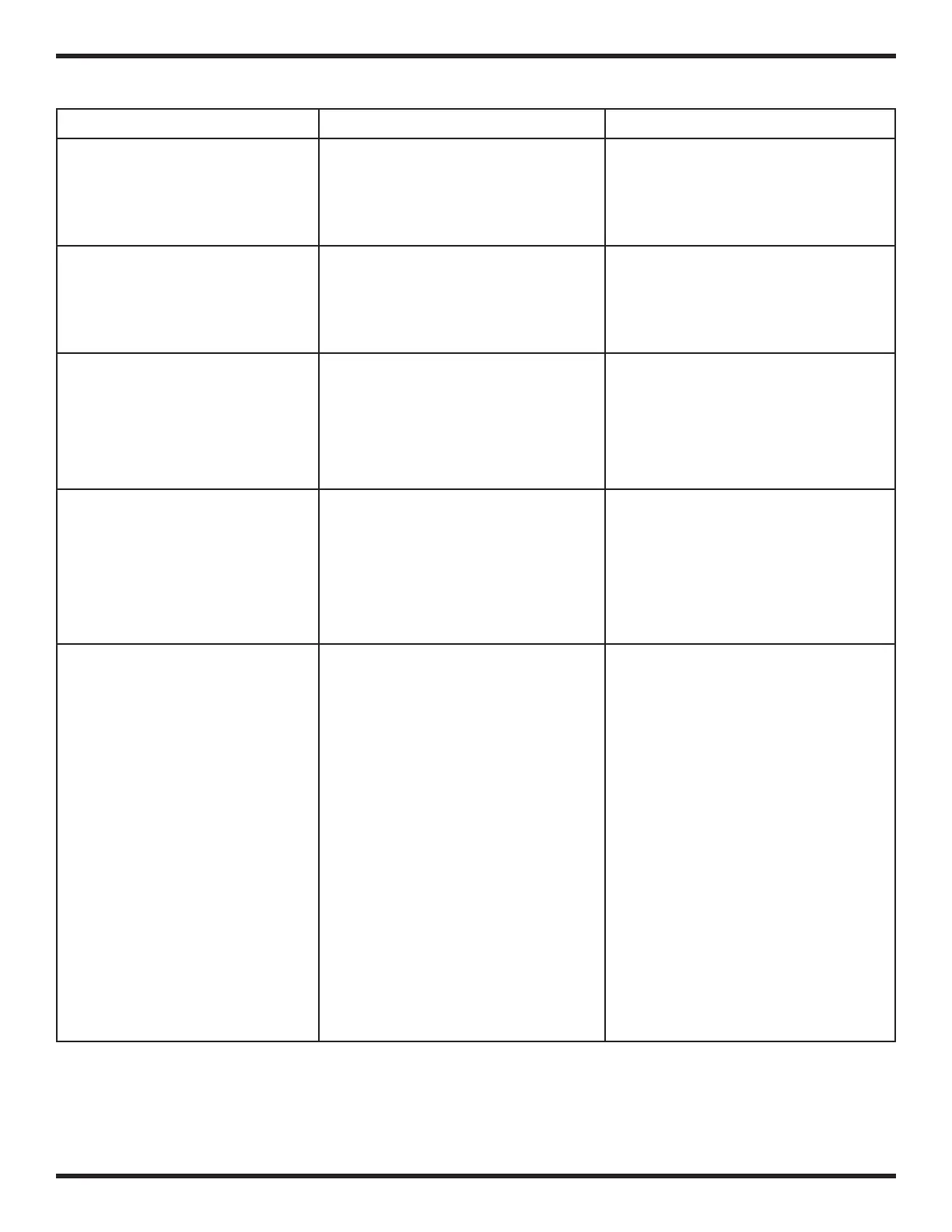

Problem Possible Cause Solution

1. Timer does not display

time of day.

a. Transformer unplugged

b. No electric power at outlet

c. Defective transformer

d. Defective PC board

a. Connect power

b. Repair outlet or use working

outlet

c. Replace transformer

d. Replace PC board

2. Timer does not display

correct time of day.

a. Switched outlet

b. Power outage

c. Defective PC board

a. Use uninterrupted outlet

b. Reset time of day

c. Replace PC board

3. No softening/ltering dis-

play when water is owing.

a. Bypass valve in bypass position

b. Meter connection disconnect-

ed

c. Restricted/stalled meter turbine

d. Defective meter

e. Defective PC board

a. Put bypass valve in service posi-

tion

b. Connect meter to PC board

c. Remove meter and check for

rotation or foreign material

d. Replace meter

e. Replace PC board

4. Control valve regener-

ates at wrong time of day.

a. Power outages

b. Time of day not set correctly

c. Time of regeneration incorrect

d. Control valve set at “on O” (im-

mediate regeneration)

e. Control valve set at NORMAL +

O

a. Reset control valve to correct

time of day

b. Reset to correct time of day

c. Reset regeneration time

d. Check control valve set-up pro-

cedure regeneration time option

e. Check control valve set-up pro-

cedure regeneration time option

5. ERROR followed by Code

number:

Error Code 101- Unable to recog-

nize start of regeneration

Error Code 102 - Unexpected

stall

Error Code 103 - Motor ran too

long; timed out trying to reach

next cycle position

Error Code 104 - Motor ran too

long; timed out trying to reach

home position

If other Error Codes display, con-

tact the factory.

a. Control valve has just been

serviced

b. Foreign matter is lodged in con-

trol valve

c. High drive forces on piston

d. Control valve piston not in home

position

e. Motor not inserted fully to en-

gage pinion, motor wires broken

or disconnected, motor failure

f. Drive gear label dirty or dam-

aged, missing or broken gear

g. Drive bracket incorrectly

aligned to back plate

h. PC board is damaged or defec-

tive

i. PC board incorrectly aligned to

drive bracket

a. Press NEXT and REGEN for 3

seconds or unplug power source

jack (black wire) and plug back

in to reset control valve

b. Check piston and spacer stack

assembly for foreign matter

c. Replace piston(s) and spacer

stack assembly

d. Press NEXT and REGEN for 3

seconds or unplug power source

jack (black wire) and plug back

in to reset control valve

e. Check motor and wiring. Re-

place motor if necessary. Re-

place or clean drive gear.

f. Replace or clean drive gear

g. Reset drive bracket properly

h. Replace PC board

i. Ensure PC board is correctly

snapped onto drive bracket

Crusader Pro, Deluxe, & Enhanced Systems Owner’s Manual 2020

Loading...

Loading...