3

ULTRASONIC CLEANING SYSTEMS ULTRASONIC CLEANING SYSTEMS

GENERAL VIEW

You have just purchased a CRYSTAL CLEAN ultrasonic

cleaning

system. We appreciate the confidence shown by

purchasing a CRYSTAL CLEAN equipment.

Each CRYSTAL CLEAN machine has been carefully tested

and has passed our quality controls. However, the lifetime of

the machine depends largely on you, so we recommend you

to consider the information contained in this manual at the

start up and use of your ultrasound equipment. Give special

attention to the instructions that we detail below.

FORESEEN USE

Motor clean range equipment is specially designed for

cleaning engines, engine parts and accessories.

This equipment is designed to cover the needs not only

of car repair shops but also for marine and cogeneration

engines, aeronautic industry and grinding and

remanufacturing engine workshops.

Crystal Clean products achieve a high cleaning quality,

effectively removing any kind of dust: greases, oil or

carbon deposits. Since cleaning is carried out by

immersion, the ultrasonic cleaning achieves a high quality

result in every hard-to-reach areas.

SAFETY WARNINGS

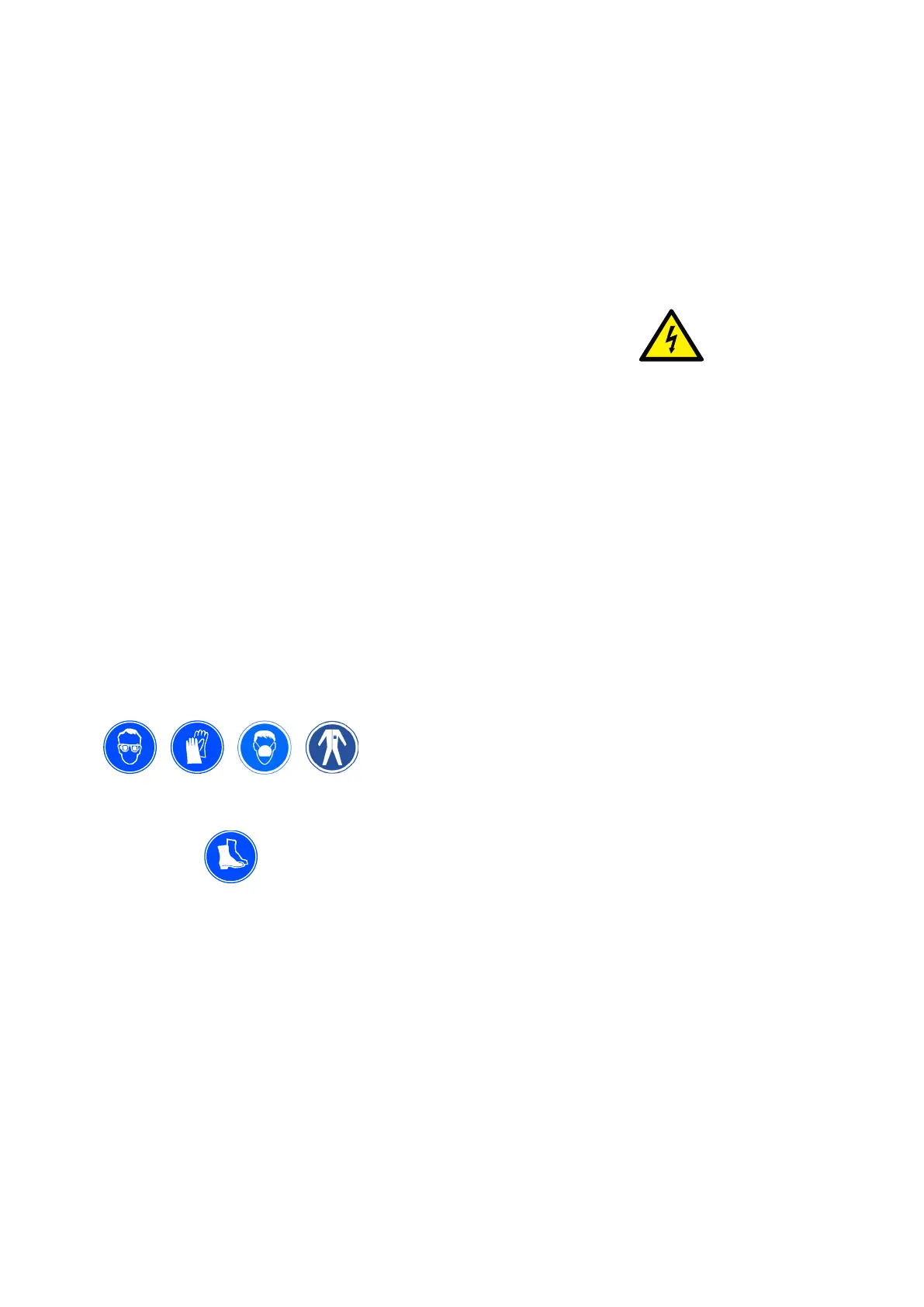

1. Use protective equipment against thermal, chemical

and splashes risk (gloves, goggles, protective clothing,

mask) according safety data sheet of the chemical

product. Gloves and clothes must be thermal

and chemical protective and glasses completely cover

both eyes and the mask should cover both the mouth

and the nostrils.

2. Use safety boots to prevent injury from possible falls of

parts to be cleaned.

3. Perform cleaning and maintenance while the machine

is off.

4. Do not transport the machine with water in the tank.

5. Do not work with the machine if damages are detected.

6. Do not introduce in the machine parts larger than

those indicated as useful measures in the technical

specications.

7. When draining the tank for cleaning, wait until the

temperature lowers befor pouring cold water for

cleaning.

8. Keep the lid open while tank is being drained.

9. Use the machine only for ultrasonic cleaning of parts. It

is not designed for any other applications.

10. Introduce softly the load and center on platform against

rear side (if equipment has platform).

11. Do not place the machine against direct sunlight,

nor next to a heat source. In such cases the internal

temperature of the machine increases and may result

in a malfunction.

12. This machine is designed for indoor use only. In case

of outdoor use, the equipment can be damaged or an

electrical failure may occur.

13. Do not use power wires or plugs in bad condition.

14. Make sure you have a good grounding and appropriate

supply voltage according to the specications of

the ultrasound machine. The electrical installation

where the machine is connected must comply with

current regulations and must be installed by qualied

technicians.

15. Do not touch or unplug the power wire with wet hands.

16. Do not access to the control registers. These areas are

indicated on the machine with this symbol.

In case of disassemble any guard ensure to cut the

electrical and pneumatic supplies before. All the guards

must be assembled again before start the machine

again. Do not work with the guards removed.

17. Disconnect the equipment from the electric network or

in case of a long inactivity

18. During the test and maintenance of transducers,

generator y or any other electric element, it is required

to check that the main switch (which is blocked with a

lock) is on the OFF position or “switched off”, and also

it’s advisable to unplug the machine. This way, we

make sure that the main energy source is switched off.

Otherwise, there is a risk of electric shock.

19. When handling the machine without taking the measures

mentioned in the previous point, the corresponding

personal protective equipment against electrical

hazards must be used.

20. Do not drop any heavy bodies in the tank or press

buttons with sharp objects. It can cause serious damage

to the equipment or electric shock.

21. The transducers are located at the bottom of the tank.

It is very important to avoid hitting the transducers box

and avoid placing parts directly on it.

22. ALWAYS OPEN THE LID before activating the rise of

the platform.

23. Do not spill liquids such as water, acid or alkaline liquids

near the control panel.

24. If a acid cleaning liquid is used the machine may be

damaged, depending of how corrosive the used product

is. Therefore consult us about the product you will

use if it does not belong to those recommended by

CRYSTAL CLEAN®. In any case, it is always necessary

to consider the measures of use and safety of the

product itself, especially those relating to the volatility

and the volume of product to use.

25. The equipment is designed to work with neutral and

basic products (pH above 6,5).

26. Do not use products with a pH lower tan 6,5. In case

of doing so, the machine could be seriously damaged.

27. Do not use ammable products.

28. The working area must be properly ventilated and

workers must be aware of the posible hazards of the

cleaning products that are used. It’s necessary to read

Loading...

Loading...