4

ULTRASONIC CLEANING SYSTEMS ULTRASONIC CLEANING SYSTEMS

the safety data sheets before using the product.

Trapping hazard with the machines:

1. Work clothes should t the body and the operator must

not wear any clothing or hanging rings, bracelets,

chains... which may be caught with the moving parts of

the machine causing an injury to the operator.

2. Do not modify nor remove the coverings and protections

of the machine.

3. Do not activate the plataform while there is any body part

inside the tank.

Risk of electrical accidents:

1. Check that the machine, equipments and instalations

are in good condition

2. Stick to the guidelines given in the manuals regarding

disconnection and maintenance of electrical appliances.

3. Do not use equipment when wet, when the operator

is wet or in the presence of water or moisture. The

electrical equipment will be deposited in dry places and

should never get wet.

4. If a fault or malfunction is detected, the operator must call

the Maintenance Service (phone number is indicated in

last page) and he should never try to repair it by himself.

5. In case of malfunction, the operator must inform the rest

of his coworkers, stop using the equipments and prevent

the rest of the workers from using them.

6. Equipment and individual protections used must be

certied.

If you have to work in electrical installations, please remember:

1. Cut off all voltage sources.

2. Block breaking devices (switches, circuit breakers, etc.).

3. Verify the voltage absence.

4. Ground and short-circuit all possible voltage sources.

5. Demarcate and mark out the working area.

This list of safety warnings do not include all possible

misuse of the machine, but it describes the most

predictable. The person responsible for the safety at

the machine owner company must be commissioned to

assess, monitor and control the use of this machine.

SET UP

1. The machine is supplied packed. Check that the

packaging is in good condition before removing it. When

removing the packaging, do not use sharp elements such

as scissors or cutters to avoid marking the machine.

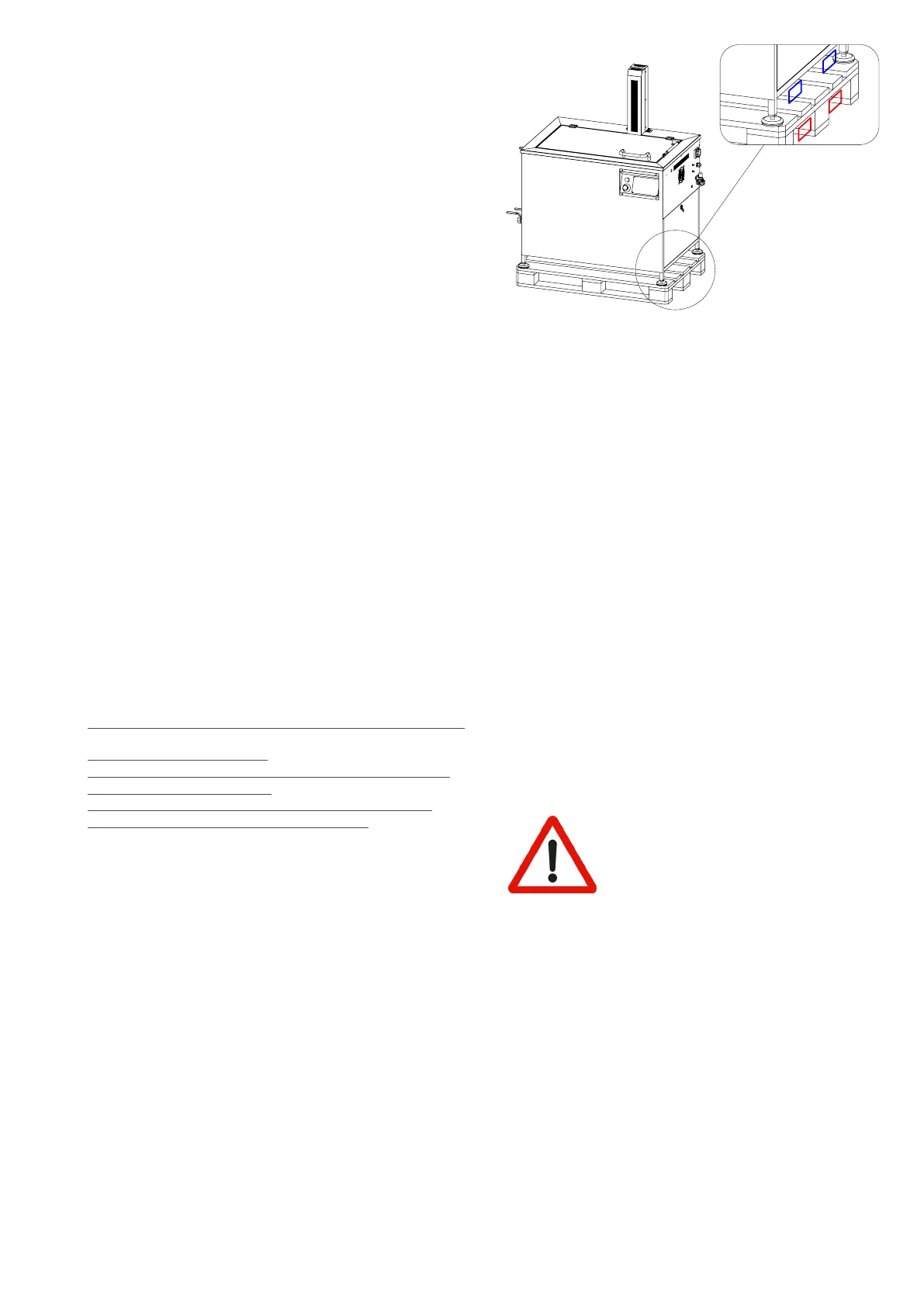

2. Use a forklift to move the machine and make sure that

you use the red points of support when using a pallet and

the blue ones when lifting the machine directly.

3. Distance the unit 300mm / 11.81”. or more from the

walls or from other machines, since the semiconductors

integrated into the generator make it temperature

sensitive. The high temperature may cause malfunction.

4. Connect to a power source of appropriate voltage as

indicated on the equipment. Always ensure the machine

is properly grounded. See equipment specifications.

5. The cleaning tank must be placed horizontally on a firm

surface and leveled.

6. The equipment must be placed in a dry place.

7. The air connection must maintain a constant pressure of

6 bars. (Recommended operating pressure).

8. The size of the water connection for filling and emptying

the tank will depend on the model (See technical

specifications). If there are security overflows, they

must remain open.

BEFORE START UP

Personnel in charge of handling and operating the machine

must have training in handling it and its inherent risks. This

machine carries risks due to chemical substances, electrical

elements and tires.

IMPORTANT: READ THE MANUAL

BEFORE DOING ANY TASK WITH THE

MACHINE.

1. Connect to a suitable electrical outlet (IMPORTANT:

See equipment specifications and check the type

label on the machine).

2. Ensure that the drain valve is closed.

3. Do not operate the ultrasonic equipment without

water. When the machine is started without fluid the

transducers, the heating element and other components

get damaged immediately.

Ensure the tank is full before operating the

equipment.

4. Fill the main tank to its maximum water level. In model

with WFS up to the top of the separator connecting the

main tank with the auxillary tank (see image). Fill the

auxiliar tank by overflowing over the separator.

Loading...

Loading...