17

Troubleshooting

If engine troubles are experienced that appear to be

fuel system related, check the following areas before

adjusting the carburetor.

• Make sure the fuel tank is filled with clean, fresh

gasoline.

• Make sure the fuel tank cap vent is not blocked and

that it is operating properly.

• If the fuel tank is equipped with a shut-off valve,

make sure it is open.

• Make sure that the in-line fuel filter is clean and

unobstructed. Replace the filter if necessary.

• Make sure fuel is reaching the carburetor. Check

the fuel lines and fuel pump for restrictions or faulty

components, replace as necessary.

• Make sure the air cleaner element is clean and all

air cleaner element components are secure.

If, after checking the items listed above, the engine is

hard to start, runs roughly, or stalls at low idle speed, it

may be necessary to adjust or service the carburetor.

Adjustment

NOTE: Engines may have a fixed idle or limiter cap on

the idle fuel adjusting needle. Step 2 can only be

performed within the limits allowed by the cap.

1. Start the engine and run at half throttle for five to 10

minutes to warm up. The engine must be warm

before performing steps 2 and 3.

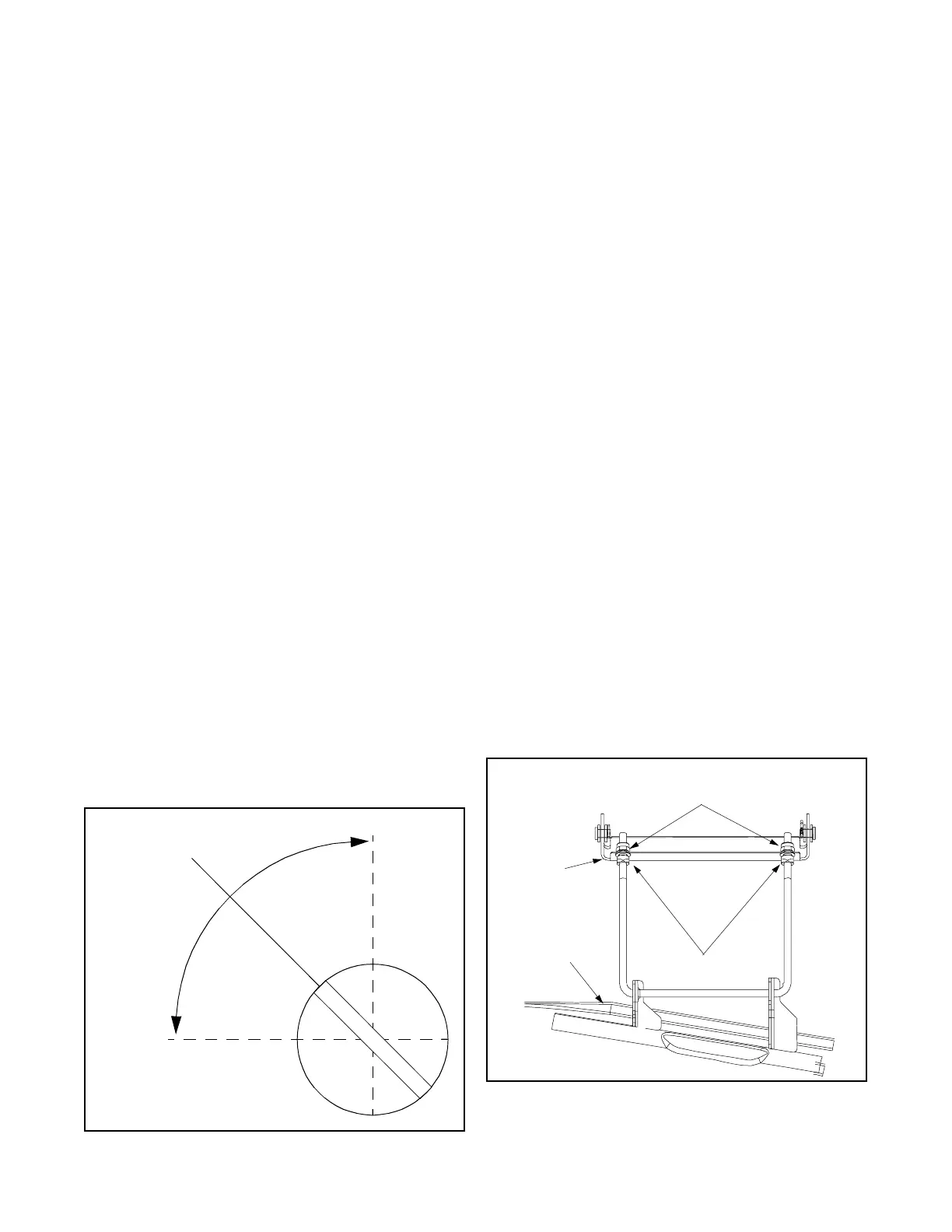

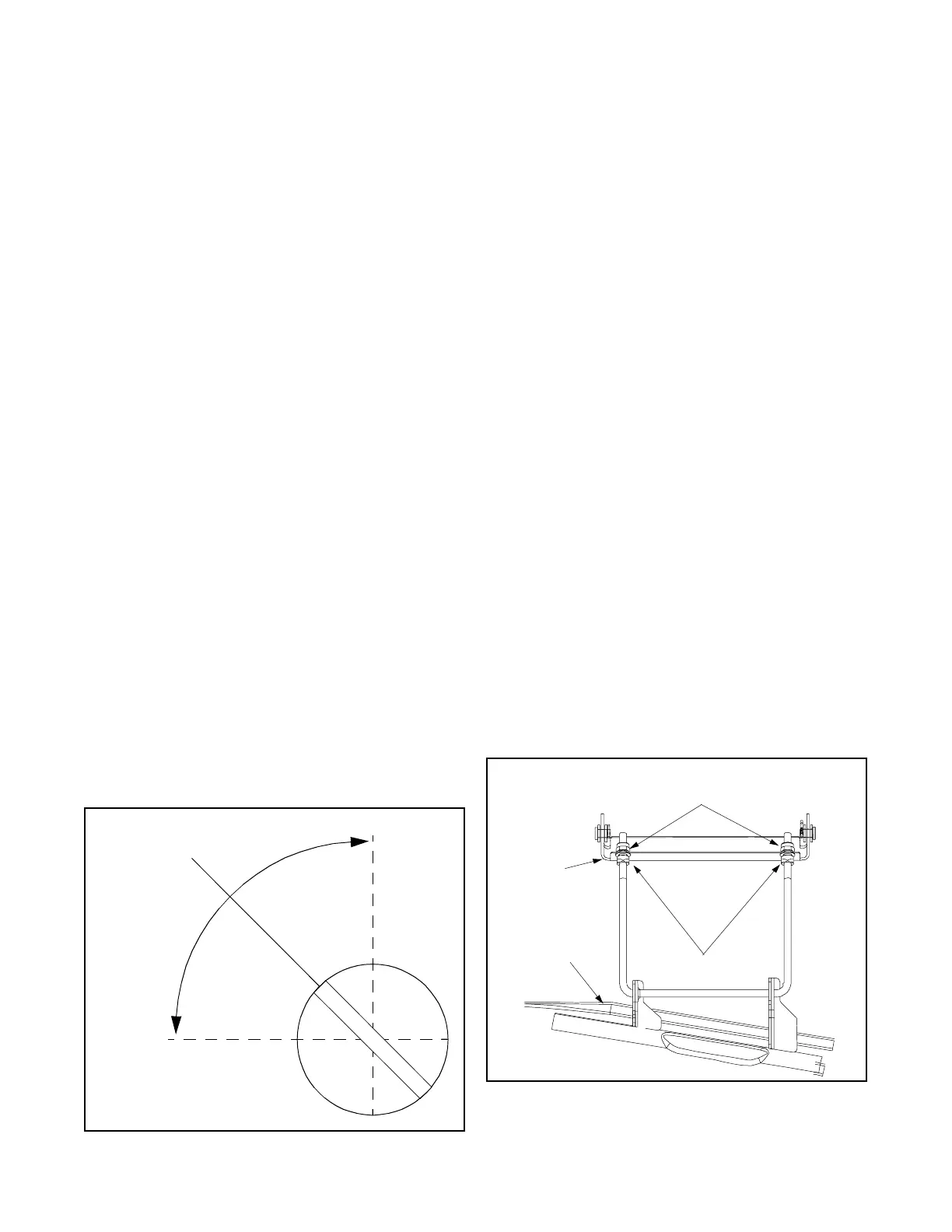

2. Low Idle Fuel Needle Setting: Place the throttle

into the “idle” or “slow” position. Turn the low idle

fuel adjusting needle out (counterclockwise) from

the preliminary setting until engine speed

decreases (rich). Note the position of the needle.

Now turn the adjusting needle in (clockwise). The

engine speed may increase, then it will decrease as

the needle is turned in (lean). Note the position of

the needle. Set the adjusting needle midway

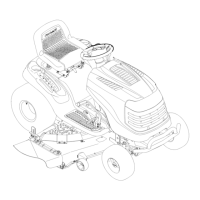

between the rich and lean settings. See Figure 13.

Figure 13

3. Low Idle Speed Setting: Place the throttle control

into the “idle” or “slow” position. Set the low idle

speed to 1200 RPM* (± 75 RPM) by turning the low idle

speed adjusting screw in or out. Check the speed

using a tachometer.

NOTE: To ensure best results when setting the low

idle fuel needle, the low idle speed must not exceed

1200 RPM (± 75 RPM).

Leveling the Deck

NOTE: Check the tractor’s tire pressure before

performing any deck leveling adjustments. Refer to

Tires on page 24 for information regarding tire pressure.

Front To Rear

The front of the cutting deck is supported by a stabilizer

bar that can adjusted to level the deck from front to rear.

The front of the deck should be between 1/4-inch and

3/8-inch lower than the rear of the deck. Adjust if

necessary as follows:

• With the tractor parked on a firm, level surface,

place the deck lift lever in the top notch (highest

position) and rotate the blade nearest the discharge

chute so that it is parallel with the tractor.

• Measure the distance from the front of the blade tip

to the ground and the rear of the blade tip to the

ground.

• The first measurement taken should be between

1/4" and 3/8" less than the second measurement.

• Determine the approximate distance necessary for

proper adjustment and proceed, if necessary, to the

next step.

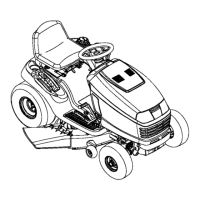

• Loosen the two jam nuts on the rear side of the

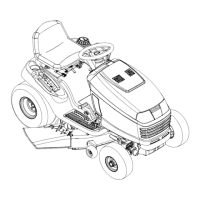

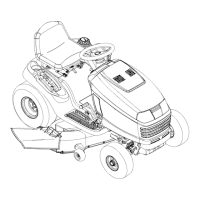

deck stabilizer bracket. See Figure 14.

Figure 14

Lean

Rich

Adjust to Midpoint

Jam

Deck

Stabilizer

Bracket

Nuts

Lock

Nuts

Deck

Loading...

Loading...