-12-

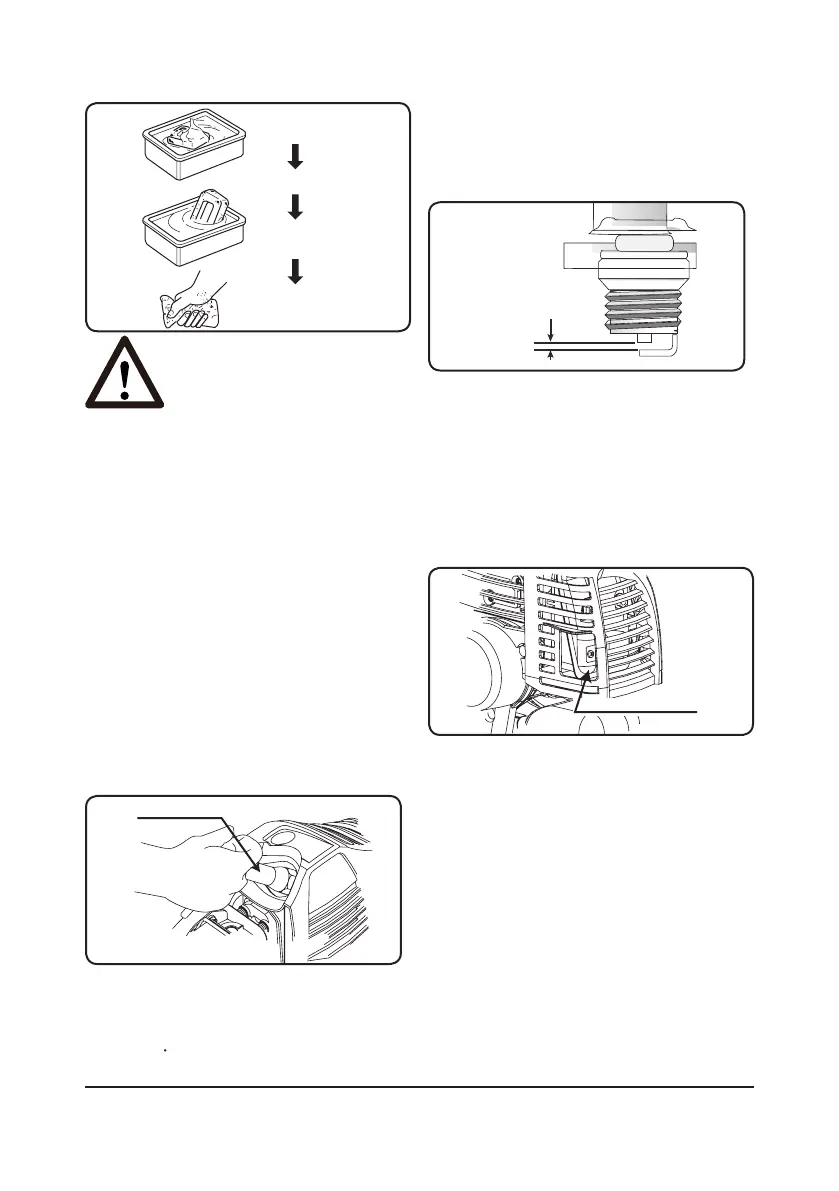

Washing

Drying

Engine Oil

Squeezing

WARNING

Improper element cleaning can result in

engine damage.Do not use compressed air

to clean or dry element. Never use gasoline.

Do not operate engine with air lter parts

removed.

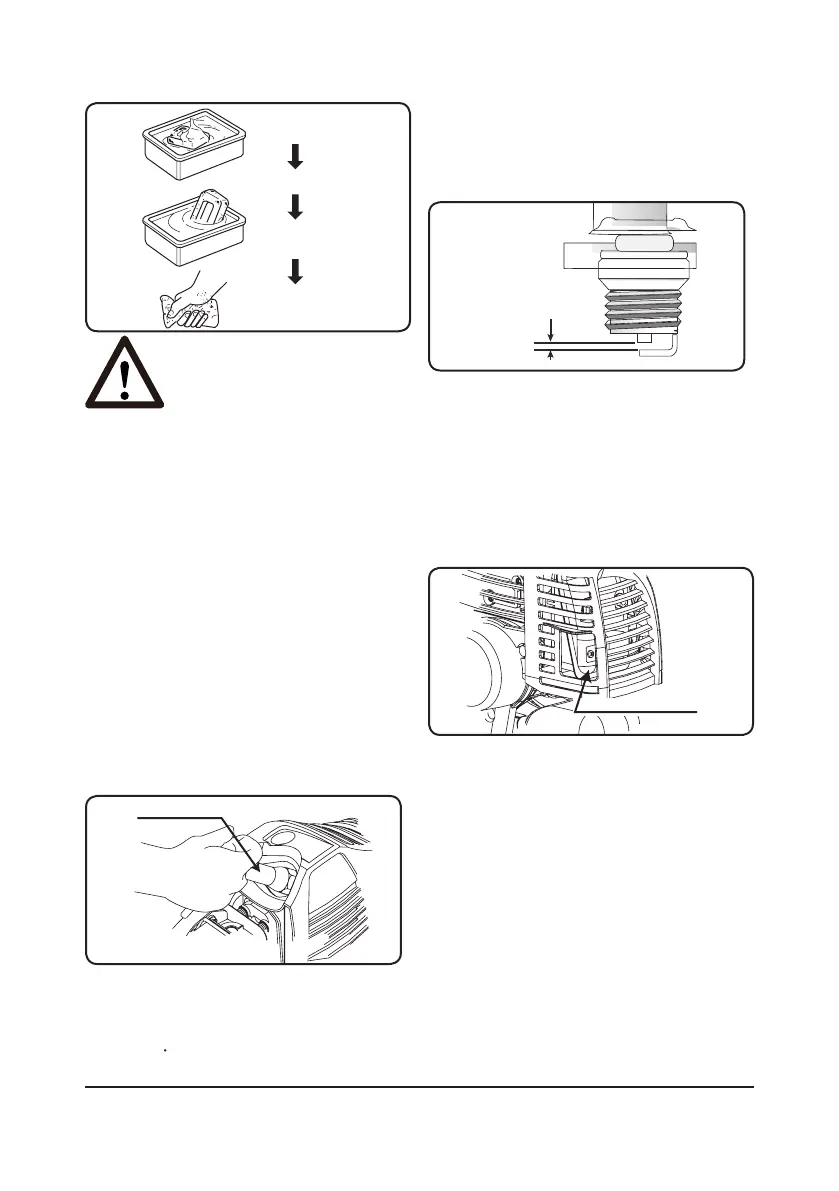

SPARK PLUG

After every 50 operating hours take out the spark

plug and check its condition.

1. Switch o the engine and allow it to cool

down

2. Grasp the plug wire rmly and pull it from

the spark plug.

3. Wipe o dust or dirt around spark plug.

4. Unscrew spark plug in counterclockwise

direction with the attached spark plug

wrench.

5. Brush o carbon deposits.

6. Check and adjust spark plug gap to

0.6-0.7mm

7. Screw in the spark plug and tighten to a torque

of 14-17N M.Do not over tighten.

8. Re-attach the spark plug cap.

9. If spark plug is damaged or the unit still

cannot work well after cleaning, replace with a

new one.

10. To ensure the machine work well Please use

the specied plug.

MUFFLER

Spark Arrester Service

Every 50 hours of operation

1. Remove the spark arrester from the exhaust

hole of muer.

2. Clean deposits from the spark arrester screen

by brushing it.

3. Install the spark arrester.

Carbon Removal of Engine Internal Parts

Every 50 hours of operation or found strikingly

low engine high-speed and rule out other causes

you need to clean up the engine internal carbon

deposition.

These items must be performed with proper

tools. please do it with the assistance of

professionals or authorized dealer.

GEAR CASE

1. Rell the grease into the gearbox every 25

hours operation;

2. Use the grease pump and inject the grease

30g into the oil inlet until it comes out of the

gearbox.

3. Inject through grease nipple or grease screw.

Loading...

Loading...