Section 1

OPERATING INSTRUCTIONS

The engine operator must assume responsibility of engine care while engine is being operated.

There are comparatively few rules which operator must observe to get best service from a Cummins

Diesel Engine.

GENERAL-ALL APPLICATION

New and rebuilt Engine Break-In

S-3.8 engines are tested before being shipped

from the factory and are ready to be put to work.

You will get better life from engine by

,

1. Avoiding operation for long periods at

engine idle speeds, or at maximum

horsepower levels in excess of five

minutes.

2. Developing the habit of watching engine

instruments closely during operation and

letting up on throttle if oil temperature

reaches. 250

0

F (121

0

C) or coolant temperature

exceeds 203

0

F (95

0

C)

3. Checking engine oil level prior to engine start.

4. For continuous rating, load can be applied

after the engine is commissioned.

New or Rebuilt Engines.

Pre-Starting Instructions-First Time Priming the

Fuel System.

1. Fill fuel filter with clean No. 2 diesel fuel oil

meeting the specification outlined.

2. Check the oil level of the MICO fuel pump

with the dipstick provided.

3. Check & fill fuel tanks.

Oil Pan Capacities

High Low

(liters) (liters)

1. Fill engine with amount of oil listed as low-

level oil pan capacity.

2. Allow five (5) minutes or more for oil to drain

to the oil pan. If engine and/or oil

temperature is below 40

0

F (4

0

C), a longer

period may be required for full drain.

3. Insert dipstick into gauge tube fully seated;

hold for five (5) ten (10) seconds, then

withdraw slowly.

4. Add enough additional oil to fill engine to

listed high-level capacity. The dipstick has

mark to high & low oil level.

5. Start engine and operate at idle for 3

minutes. Stop engine wait for 10 minutes and

fill to high mark. Additional oil may be

required to fill oil filters and lines.

Do not confuse with complete oil system capacity

which also includes drilled passages, lines and

filters.

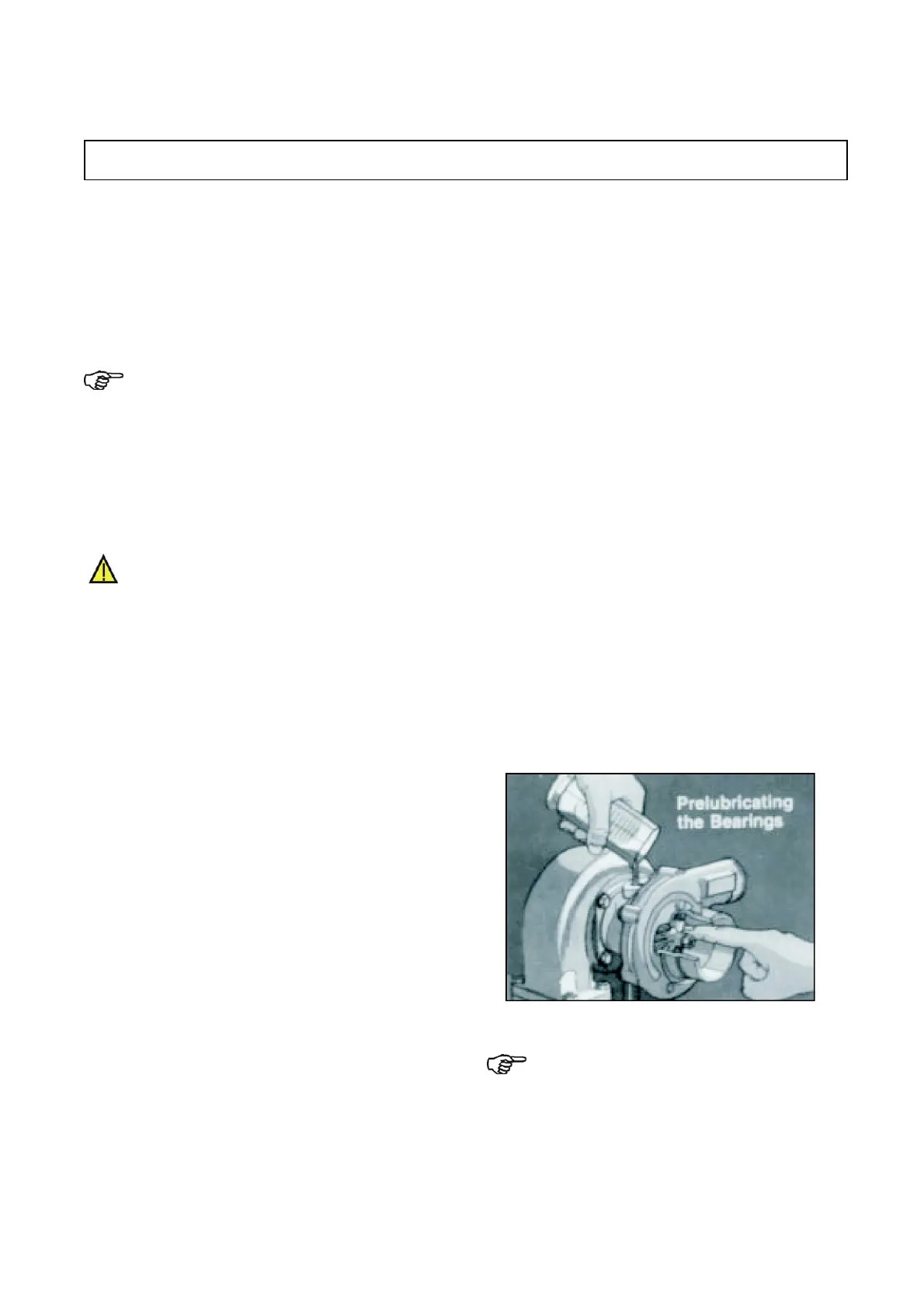

Priming the Lubricating System

Fig. 1-1 : Pre-lubricating Turbo

8 6

Workshop Manual

S3.8 Engine

A030K288 (Issue 2)

01-2010

Note : One receipt of engine by truck,

ensure unloading of the engine by

skiled personnel. The Personnel have to

use necessary personal protective

equipment to avoid accidents. Engines

are to be un loaded using the lifting

hooks fitted on the engines. During the

engine installation ensure proper

fitment of Anti Vibration

Mounting

Pad.

Note : On turbocharged engines,

remove oil inlet line from the

turbocharger and pre-lubricate bearing

by adding 2 to 3 oz. (50 to 60cc) of clean

lubricating oil. Reconnect oil supply

line.

Warning : Ensure that the shipping

bracket is removed during the engine

installation.

Loading...

Loading...