#URTIS-ANUAL/3

,/7#522%.4#/..%#4)/.3

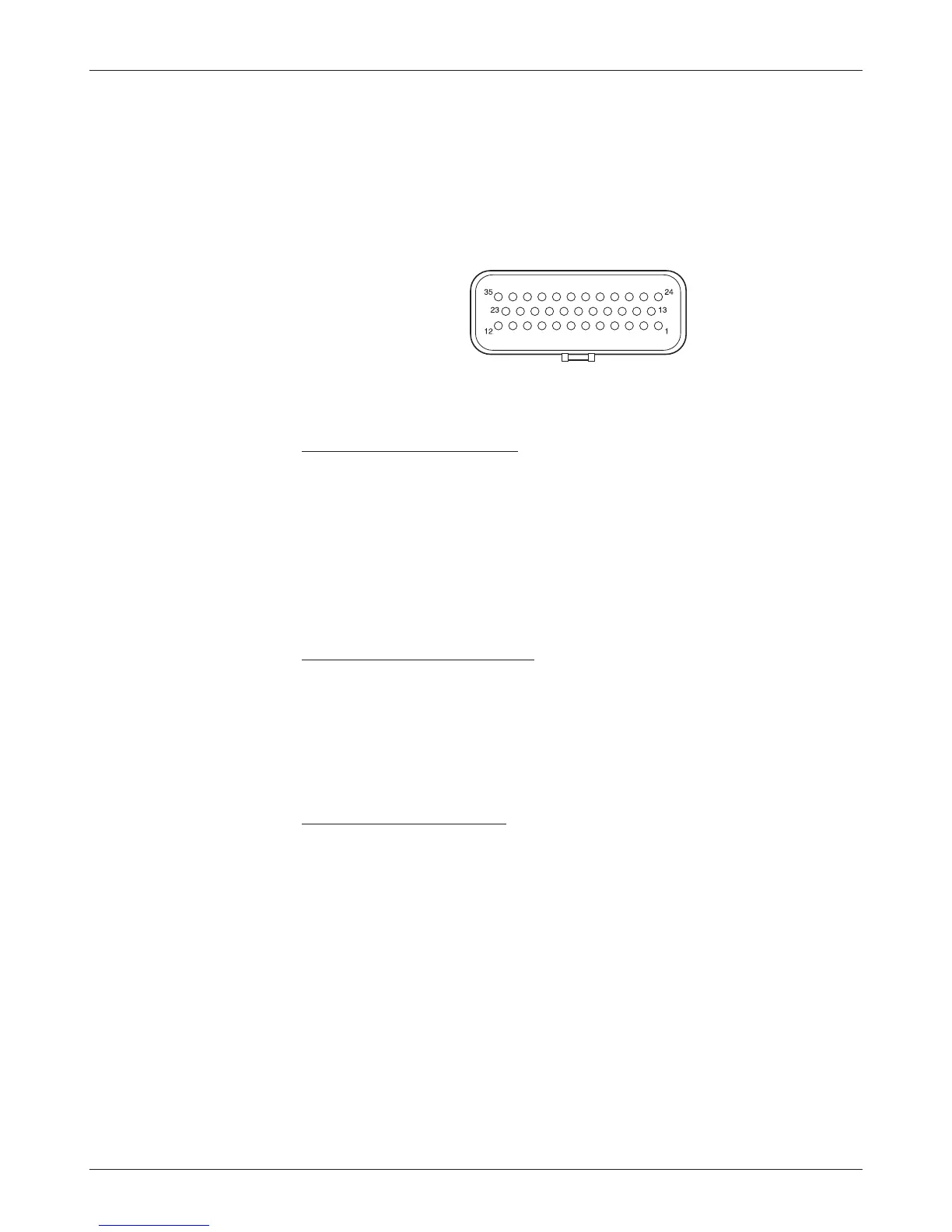

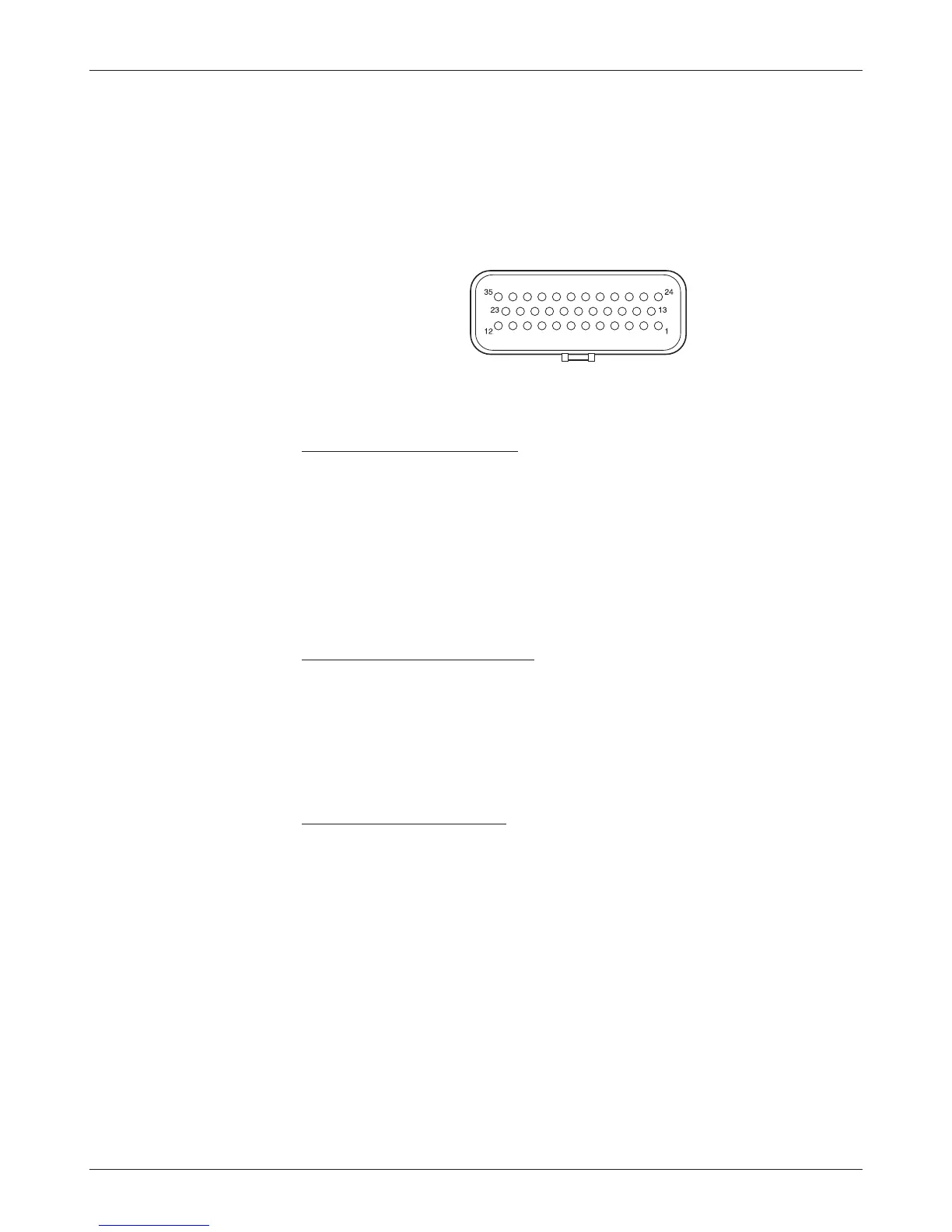

!LLLOWPOWERCONNECTIONSAREMADETHROUGHASINGLEPIN!-03%!,CON

NECTOR4HE

MATINGPLUGHOUSINGIS!-0PNANDTHECONTACTPINS

ARE!-0PN4HECONNECTORWILLACCEPTTO!7'WIREWITH

ATOMMDIAMETERTHINWALLINSULATION

4HEINDIVIDUALPINSARECHARACTERIZEDIN4ABLE

).34!,,!4)/.7)2).',OW#URRENT#ONNECTIONS

*

,OWCURRENTWIRINGRECOMMENDATIONS

-OTORENCODER0INS

!LLFOURENCODERWIRESSHOULDBEBUNDLEDTOGETHERASTHEYRUNBETWEENTHE

MOTORANDCONTROLLERLOGICCONNECTOR4HESECANOFTENBERUNWITHTHERESTOF

THELOWCURRENTWIRING HARNESS4HEENCODER CABLESSHOULD NOTBE RUN NEAR

THEMOTORCABLES)NAPPLICATIONSWHERETHISISNECESSARYSHIELDEDCABLESHOULD

BEUSEDWITHTHEGROUNDSHIELDCONNECTEDTOTHE)/GROUNDPINATONLY

THECONTROLLERSIDE)NEXTREMEAPPLICATIONSCOMMONMODElLTERSEGFERRITE

BEADSCOULDBEUSED

#!.BUS0INS

)T IS RECOMMENDED THAT THE#!. WIRES BE RUN AS A TWISTED PAIR (OWEVER

MANYSUCCESSFULAPPLICATIONSATK"AUDARERUNWITHOUTTWISTINGSIMPLY

USINGTWOLINESBUNDLEDINWITHTHERESTOFTHELOWCURRENTWIRING#!.WIRING

SHOULDBEKEPTAWAYFROMTHEHIGHCURRENTCABLESANDCROSSITATRIGHTANGLES

WHENNECESSARY

!LLOTHERLOWCURRENTWIRING

4HEREMAININGLOWCURRENTWIRINGSHOULDBERUNACCORDINGTOSTANDARDPRACTICES

2UNNINGLOWCURRENTWIRINGPARALLELTOTHEHIGHCURRENTWIRINGSHOULDALWAYS

BEAVOIDEDANDCROSSITATRIGHTANGLESWHENNECESSARY

Loading...

Loading...