24

Air at ambient temperature shall be used as the pressure medium. The

valve shall be observed for leakage for at least 1 minute. The leakage rate

in bubbles per minutes shall not exceed the numbers listed in Table 10.1.

For an 0-ring seated valve, there shall be no leakage for 1 minute

(Zero bubbles per minute @ 95% of set pressure). (Figure 10.1)

Steam Testing

Steam service pressure relief valves which are set and adjusted on steam

shall be leak-tested on steam visualIy using a black background. There

shall be no visible leakage from the valve outlet when the inlet pressure is

held at 90% of the set pressure after popping and reseating. For set

pressure below 50 psig this test shall be conducted at 5 psig below set

pressure. The valve shall be observed for leakage for at least 1 minute.

This criteria applies to both metal and o-ring seated valves.

Liquid Testing

Liquid service pressure relief valves are set and adjusted on water shall be

leak-tested on water at near ambient conditions. Before starting the seat

tightness test, the set pressure shall be verified, and the outlet body bowl

shall be filled with water, which shall be allowed to stabilize with no visible

flow from the valve outlet. The inlet pressure shall be increased to the test

pressure. The valve shall be observed for 1 minute at the test pressure. For

valves set at 50 psig or below, the pressure shall be held at 5 psig below

the set pressure. Above 50 psig set pressure hold the pressure at 90% of

the set pressure.

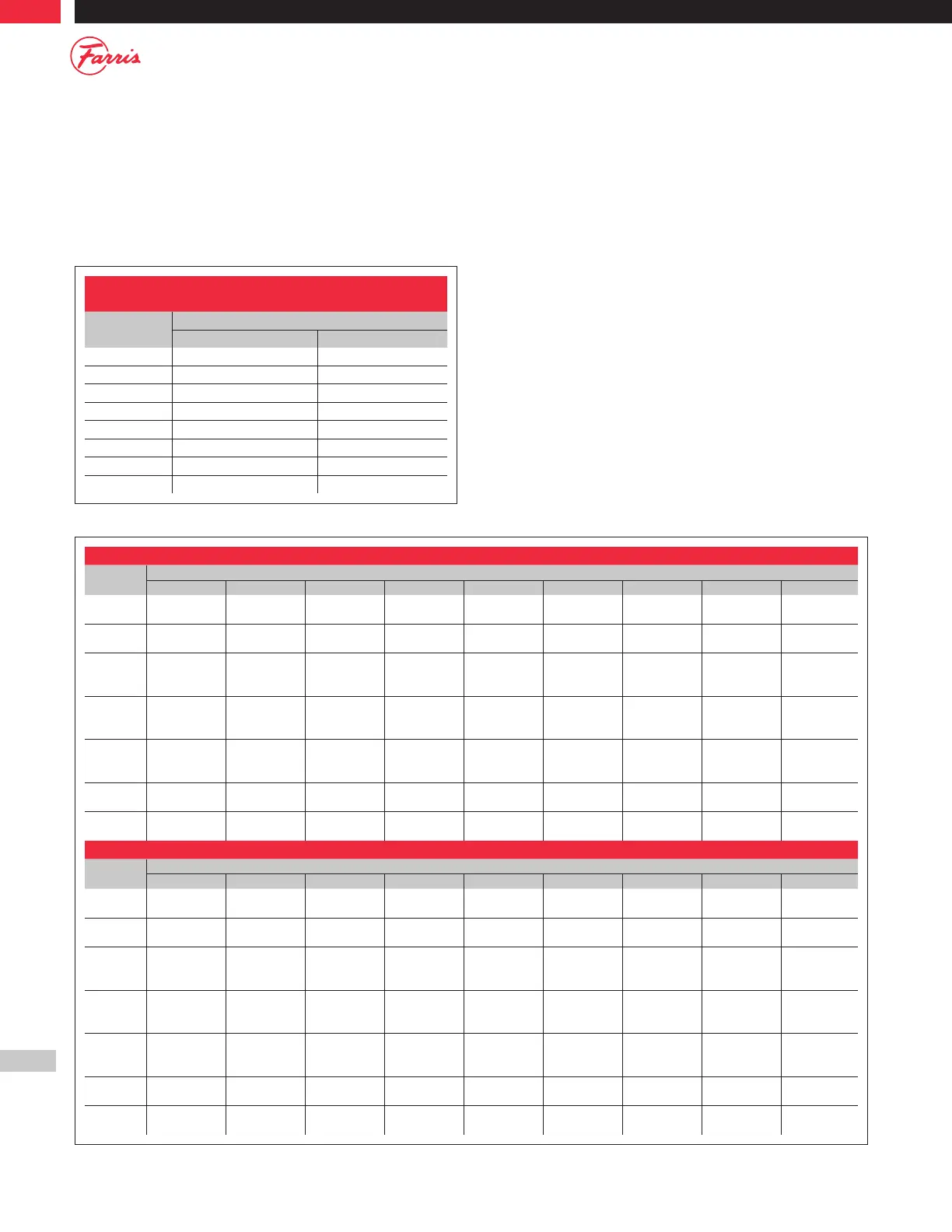

Maximum Seat Leakage Rates for

Metal-Seated Pressure Relief Valves

Set Pressure

psig

Leakage Rate (Bubbles per Minute)

F Orifice and Smaller G Orifice and Larger

15-1000 40 20

1500 60 30

2000 80 40

2500 100 50

3000 100 60

4000 100 80

5000 100 100

6000 100 100

Table 10.1

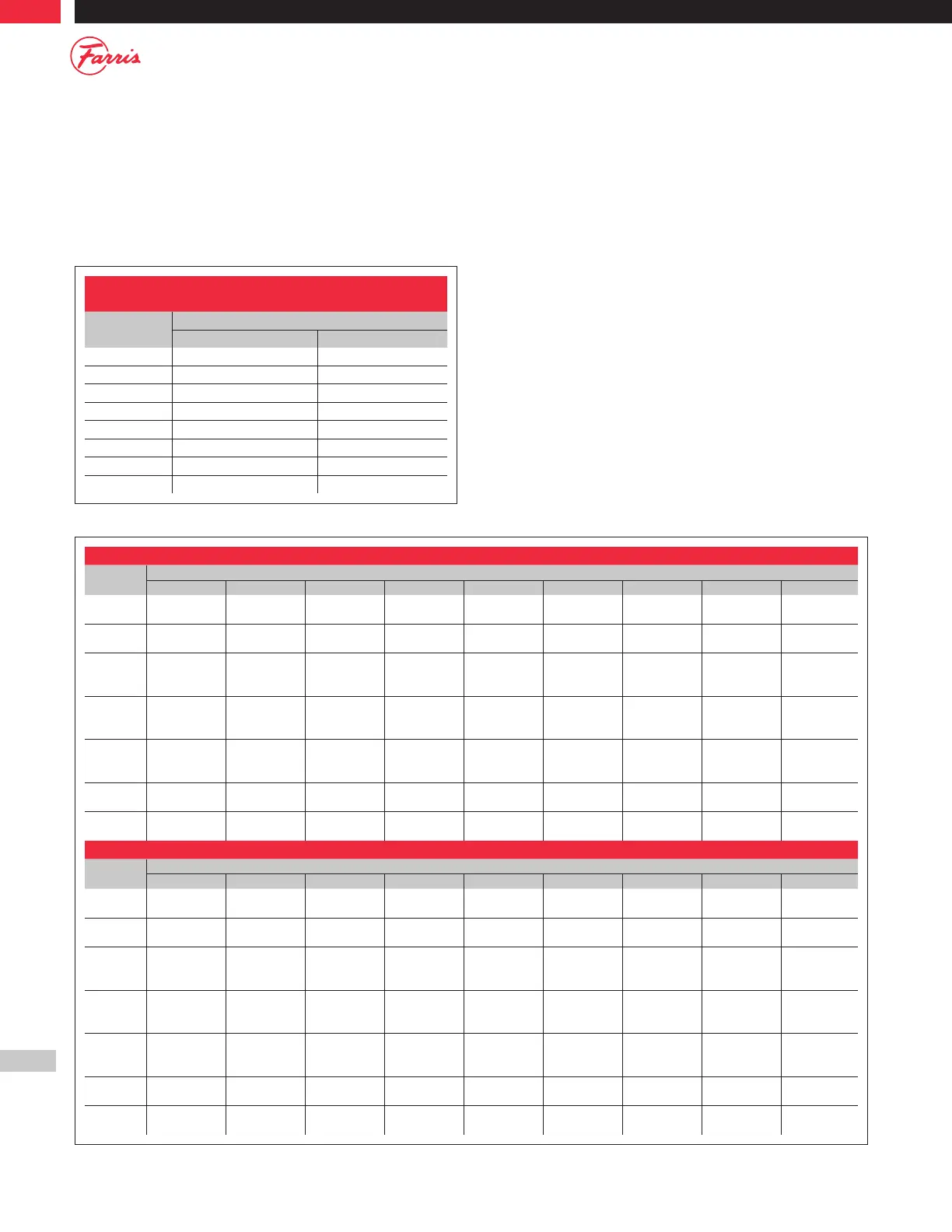

Table 10.2

Note 1: Use the second row only for “D” & “E” orifice valves purchased before July 1, 1993

Blow Down Ring Settings: Air, Gas, and Vapor Applications

Orifice

Set Pressure Range, psig

15 - 100 101 - 200 201 - 300 301 - 400 401 - 500 501 - 600 601 - 800 801 - 1000 1001 & Up

D

1

3

2

4

2

6

3

7

4

7

4

9

5

9

5

9

6

10

7

E

1

5

2

9

2

12

3

15

4

15

4

18

5

18

5

19

6

20

7

F

G

H

2

3

3

3

4

4

4

5

5

5

6

6

5

6

6

7

8

8

8

9

9

9

10

10

10

11

11

J

K

L

3

4

4

5

5

6

5

6

9

6

7

9

6

7

9

8

9

10

9

10

10

10

11

11

11

12

12

M

N

P

4

5

6

6

10

16

12

15

20

12

15

20

12

15

20

12

15

20

12

15

20

12

15

20

12

15

20

Q

R

6

4

16

16

20

20

20

20

20

–

20

–

20

–

20

–

–

–

T

U

4

4

16

16

20

20

–

–

–

–

–

–

–

–

–

–

–

–

Blow Down Ring Settings: Steam Applications

Orifice

Set Pressure Range, psig

15 - 100 101 - 200 201 - 300 301 - 400 401 - 500 501 - 600 601 - 800 801 - 1000 1001 & Up

D

1

3

2

4

3

6

4

7

5

7

6

9

7

9

8

9

9

10

10

E

1

5

2

3

2

12

4

15

5

15

6

18

7

18

8

19

9

20

10

F

G

H

2

3

3

4

5

5

5

6

6

6

7

7

7

8

8

8

9

9

9

10

10

10

11

11

12

13

13

J

K

L

3

4

4

6

6

7

6

7

7

7

8

8

8

9

9

9

10

10

10

11

11

11

12

12

13

14

14

M

N

P

4

4

4

7

7

7

7

7

7

8

8

8

9

9

11

10

10

10

11

11

11

12

12

12

14

14

14

Q

R

4

4

8

8

9

9

10

10

11

–

12

–

13

–

15

–

–

–

T

U

4

4

8

8

9

9

–

–

–

–

–

–

–

–

–

–

–

–

Loading...

Loading...