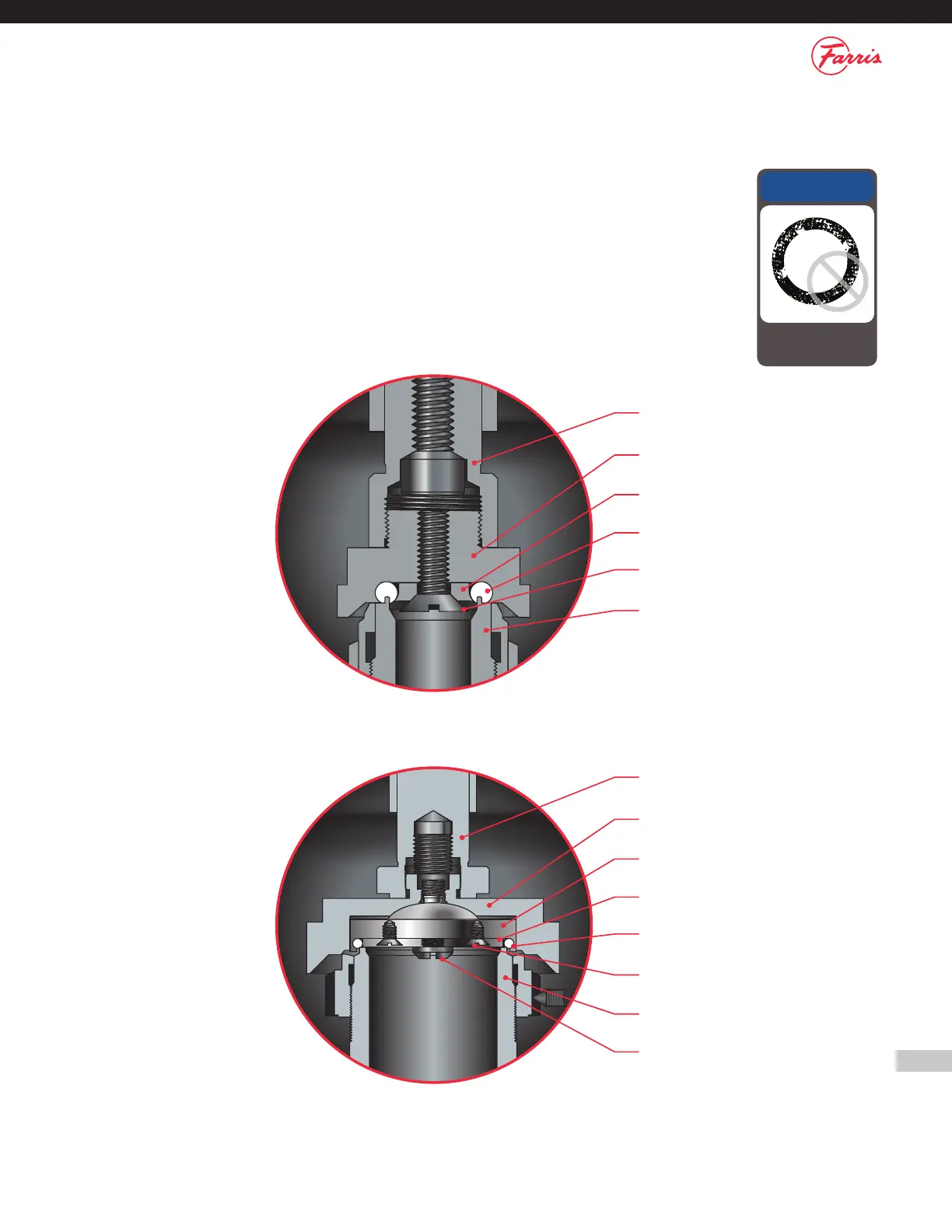

Figure C.1 – O-ring Detail D-K Orifice

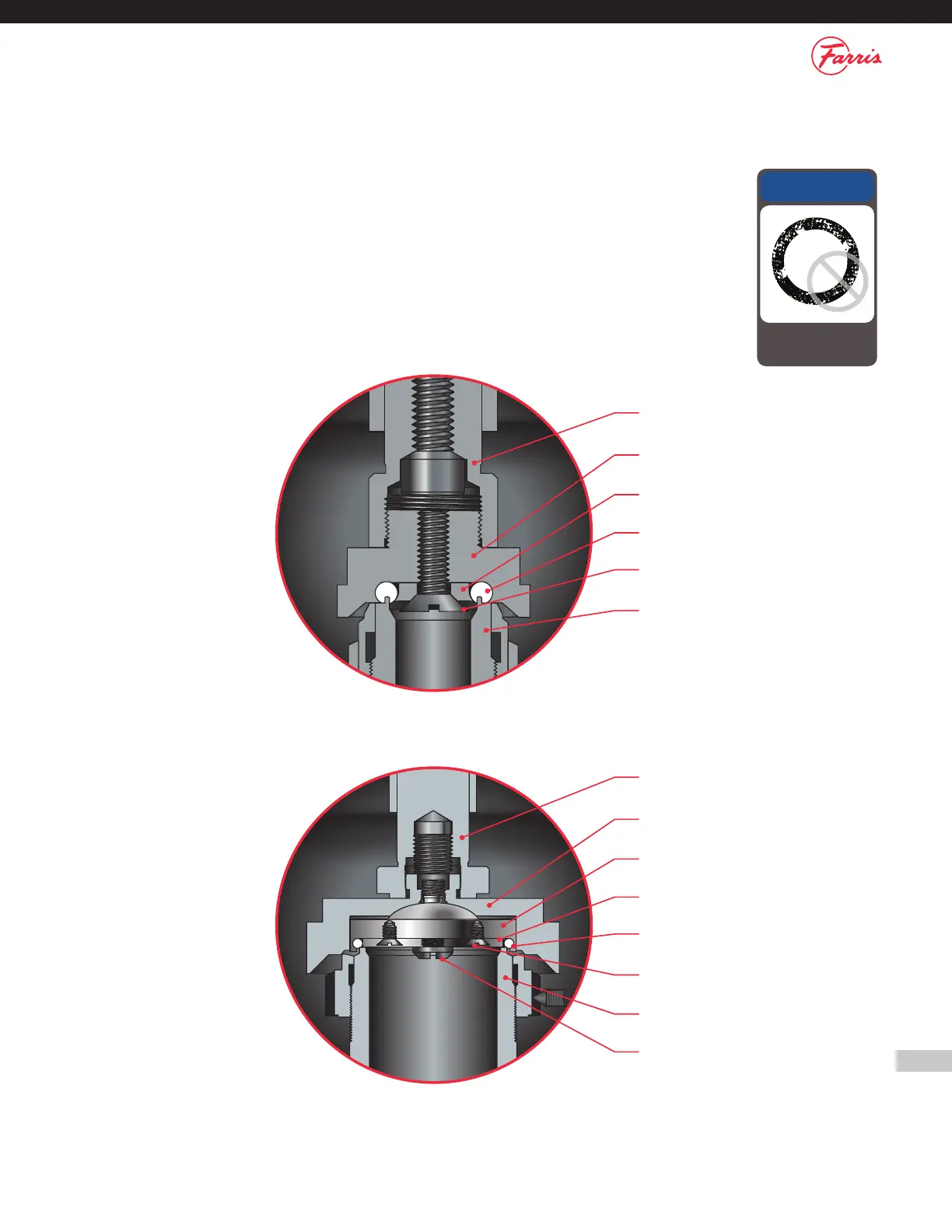

Figure C.2 – O-ring Detail L-U Orifice

31

Appendix C: O-Ring Construction

Due to corrosion, metal-to-metal seats can eventually leak. With the proper

selection of the Farris O-ring seat pressure seal, seat tightness can be

improved and maintained. Because O-rings are elastomeric, they should

be handled carefully. Typically, O-rings should be replaced during your

normal maintenance interval. O-rings are not repairable.

Standard seat tightness for O-ring seated valves is no leakage at 90% of

set pressure for both conventional and bellows valves following Farris

standard seat tightness test procedure. At set pressures of 50 psig and

below, leakage test shall be made at 5 psig below set pressure.

The O-ring seat seal option is available for

2600/2600L/2600S Series valves in both

conventional and bellows construction. Farris

Engineering has two different O-ring designs

which depend on the orifice of the pressure

relief valve.

Stem Retainer

Disc Holder

Disc

O-ring

Flat Head Machine Screw

Nozzle

Stem Retainer

Disc Holder

Disc

O-ring Retainer

O-ring

Flat Head Machine Screw

Nozzle

Jack Screw Plug

NOTICE

O-rings are not repairable

and should be replaced

if worn or damaged.

Loading...

Loading...