32

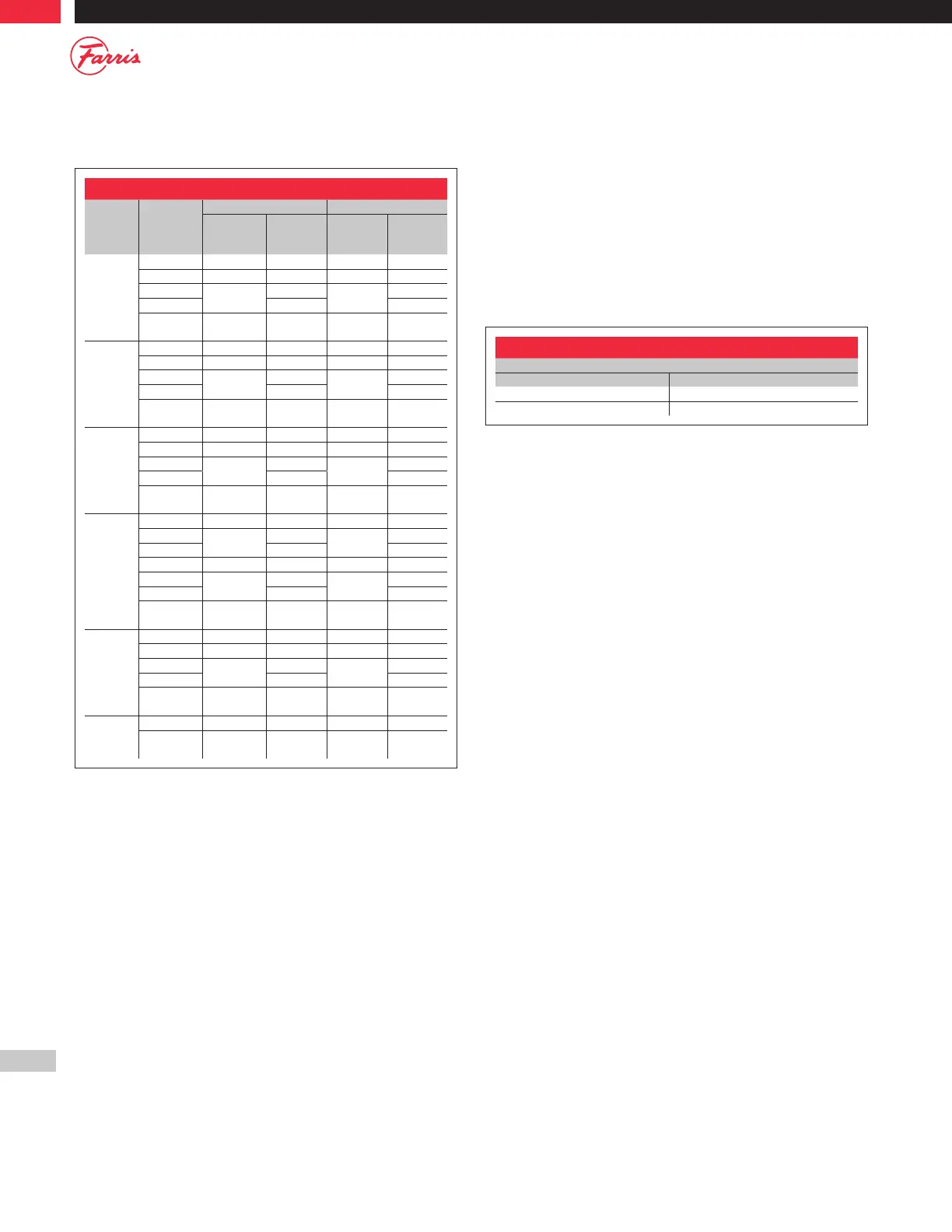

O-Ring Material Selection Table

Material

Temperature

Range °F

D to K Orifice L to T Orifice

Set

Pressure

(psig)

Durometer

(Shore A)

Set

Pressure

(psig)

Durometer

(Shore A)

Viton

4

-20 to 450 15 to 100 50 15 to 150 50

-20 to 450 101 to 650 75 150 to 450 75

-20 to 125

650 to 950

75

450 to 750

75

125 to 450 90 90

-20 to 450 950 to 1500 90

750 to

1500

90

Ethylene

Propylene

0 to 350 15 to 100 50 15 to 150 50

0 to 350 101 to 650 70 150 to 450 70

0 to 125

650 to 950

70

450 to 750

70

125 to 350 80 80

0 to 350 950 to 1500 80

750 to

1500

80

Buna N

0 to 200 15 to 100 50 15 to 100 50

0 to 200 101 to 650 70 100 to 450 70

0 to 125

650 to 950

70

150 to 750

70

125 to 200 90 90

0 to 200 950 to 1500 90

750 to

1500

90

Silicone

-150 to 450 15 to 100 50 15 to 100 50

-150 to 0

101 to 600

50

100 to 200

50

0 to 450 70 70

-150 to 450 600 to 850 70 200 to 450 70

-150 to 125

850 to 1100

70

450 to 750

70

125 to 450 80 80

-150 to 450

1100 to

1500

80

750 to

1500

80

Kalrez

-20 to 550 15 to 200 65 15 to 150 65

-20 to 550 201 to 650 80 150 to 450 80

-20 to 200

650 to 950

80

450 to 750

80

200 to 550 90 90

-20 to 550 950 to 1500 90

750 to

1500

90

Neoprene

-45 to 300 50 to 750 70 50 to 750 70

-45 to 300 751 to 1500 80

751 to

1500

80

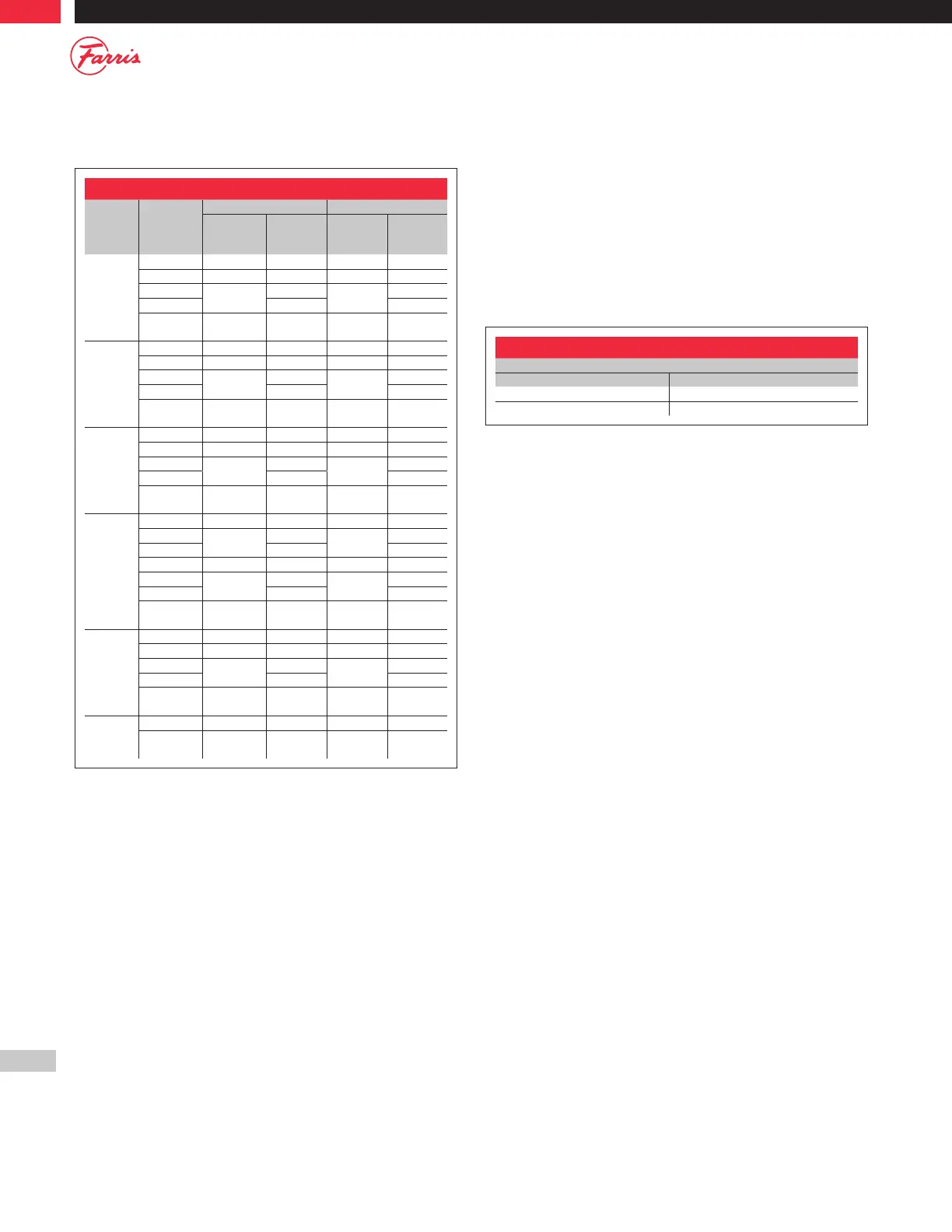

Allen Key Sizes

Disc Holder Lock Screw

Orifices Allen Key Size

D thru K 1/8"

L thru U See Table 6.1

O-Ring Seat Construction

Assembly/Disassembly Instructions

The following instructions are assembly instructions. For disassembly,

reverse the order. Parts identification can be found on page 31. Follow the

same procedures as for conventional type valves except as follows:

To connect the Disc Holder to the Stem Retainer for O-ring valves, use

the allen key sizes found in Table C.1

For D and E orifice (Bellows Construction only)(See Figure C.1):

1. Place the O-ring in the Disc Holder groove.

2. Thread the Disc into the Disc Holder/Stem Retainer.

For orifices D and E (Conventional) through K only (See Figure C.1):

1. Place the O-ring in the Disc Holder groove.

2. Place the Disc into the Disc Holder.

3. Thread the Flat Head Machine Screw through the Disc into

the Disc Holder.

For orifices L through U only (See Figure C.2)

1. Place Disc in a vice with soft jaws or in a 3-jaw chuck. Be careful not to

hold too tight as the Disc can be damaged.

2. Place the O-ring into the Disc groove.

3. Place the O-ring Retainer on the Disc.

4. Thread the Flat Head Machine Screws through the O-ring

Retainer into the Disc.

5. Thread the Jack Screw Plug into the O-ring Retainer.

6. Thread the Disc into the Disc Holder (ensure the Disc is free floating).

General Notes:

1. Viton and Kalrez are registered trademarks of DuPont Performance Elastomers.

We reserve the right to substitute comparable fluorocarbon materials.

2. PTFE seat seals available on an application basis. Consult the factory

Table C.1

Loading...

Loading...