29

Appendix B: Bellows Construction

Bellows require very thin materials to provide

the required flexibility. This results in a delicate

assembly which should be carefully handled. Do

not attempt to repair a bellows assembly. Any

pitting or surface corrosion are sure signs of

limited service life even though the bellows may

be pressure tight. All bellows assemblies should

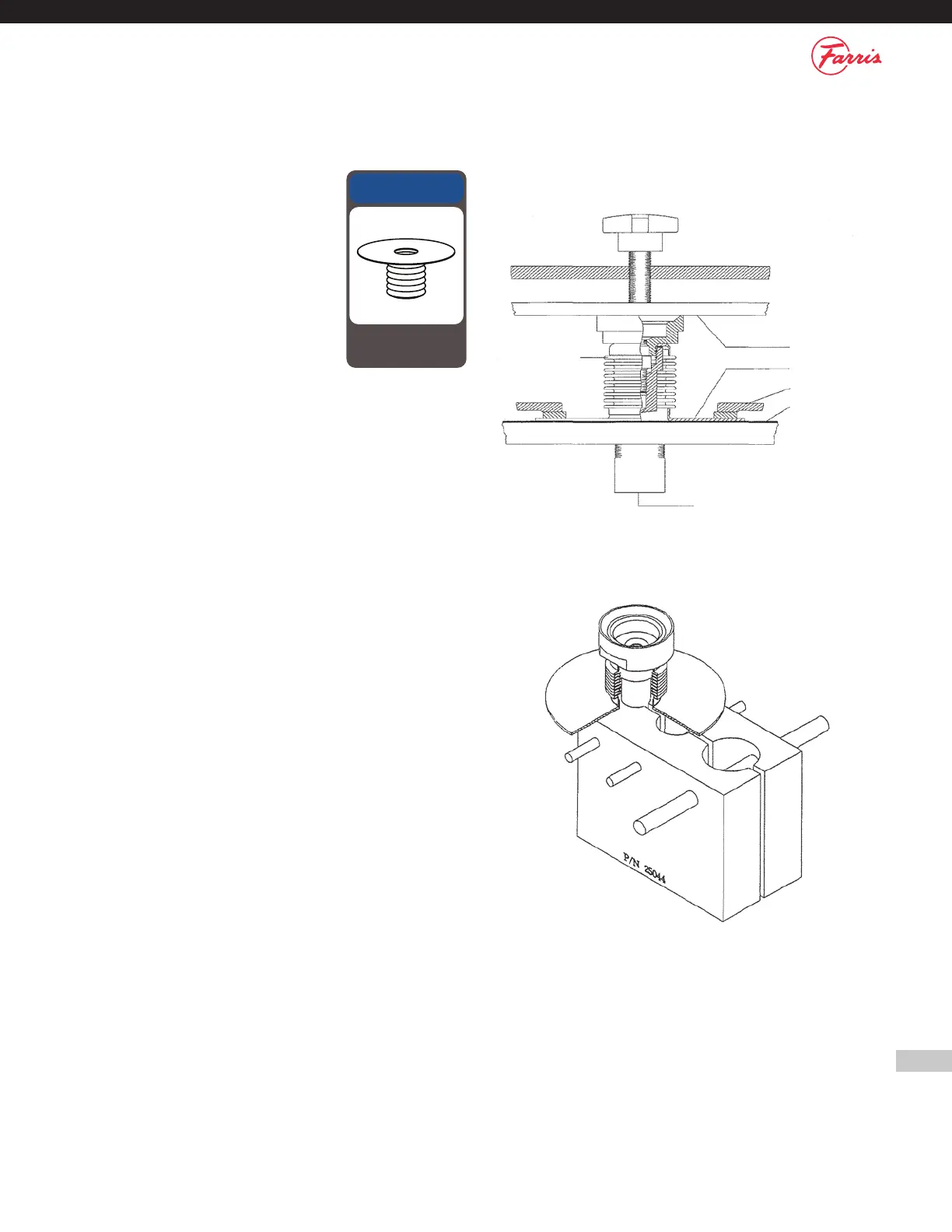

be pressure tested in accordance with Figure

B.1. Any leakage should be cause for bellows

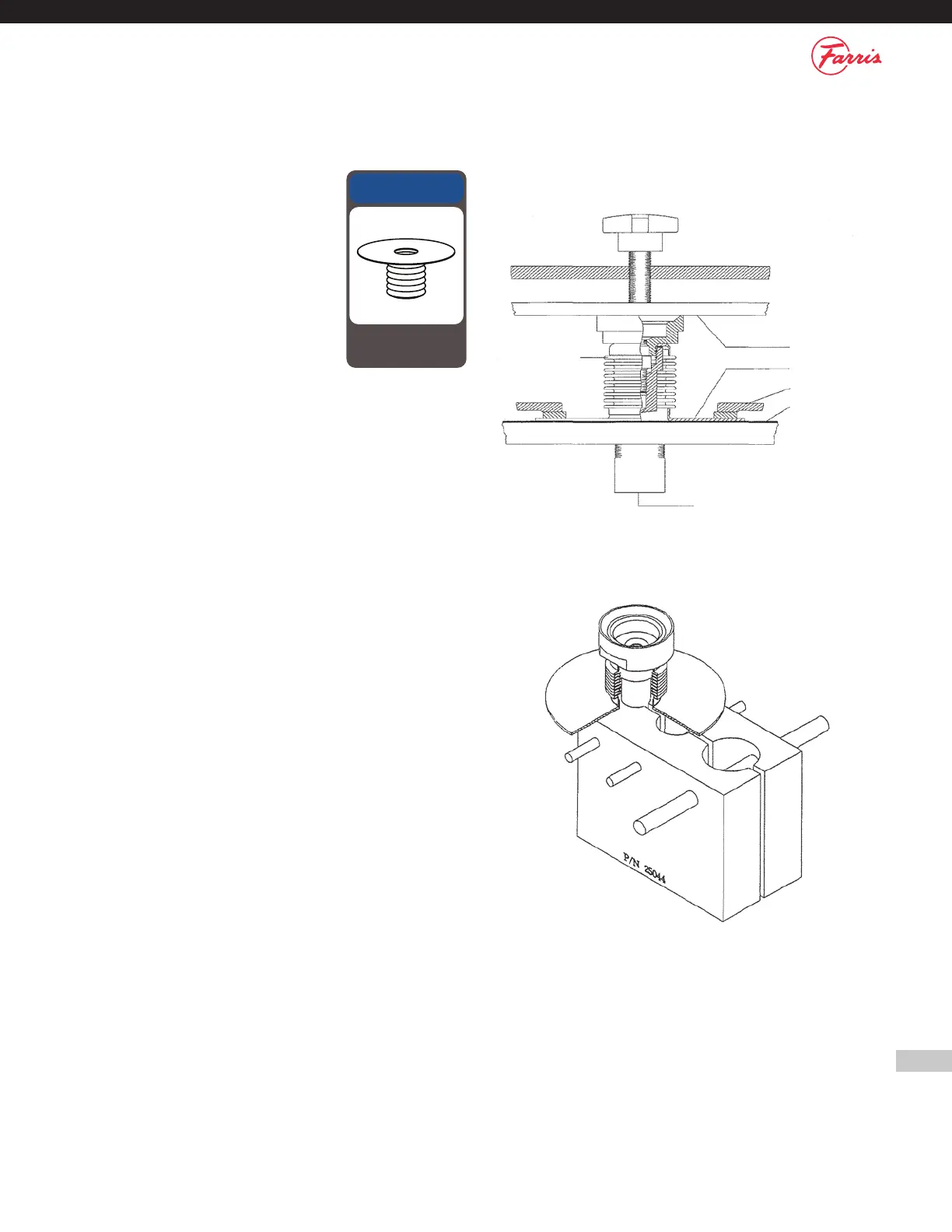

replacement. For BalanSeal bellows equipped

valves use the assembly fixture shown in Figure

B.2. Exercise care in handling the internal

assembly when equipped with a bellows as any

damage to the bellows in the form of a nick or dent will render the bellows

unfit for service. Bellows are not repairable.

1. Place bellows/stem retainer/disc holder assembly into bellows leak

test fixture with the bellows flange at the base.

2. Seal the flange of the bellows to the base of the bellows test fixture as

illustrated in Figure B.1.

3. Compress the bellows approximately 1/8 inch with a securing bar so

that the bellows does not elongate when pressure is applied as in

Figure B.1.

4. Fill the disc holder with water. Omit this step for D & E Balanseal

designs as these designs have a one piece disc holder/stem retainer.

5. Apply 30 psig pressure to the back side of the bellows.

6. Apply soapy water to bellows exterior to check

for bellows integrity.

7. If bubbles appear on bellows exterior there are pin holes

or a tear. Replace bellows and repeat the procedure.

8. Check to be sure the bellows/disc holder connection is leak tight. If

water in disc holder bubbles or the connection bubbles, tighten the

connection or replace gasket.

9. Vent pressure.

10. Release bellows assembly.

11. Air dry bellows assembly to remove soapy water.

Figure B.1 Bellows Assembly Leak Test

Restraining Bar

Bellows Flange

Flange Clamp

Rubber Gasket

Inlet Pressure Source

Bellows

Assembly

Figure B.2

NOTICE

Bellows are not repairable

and should be replaced

if damaged.

Loading...

Loading...