CONTROL SYSTEM OF DRY/SILK SPIN

I

t is a function to prevent the deformation of WOOL, SILK etc.

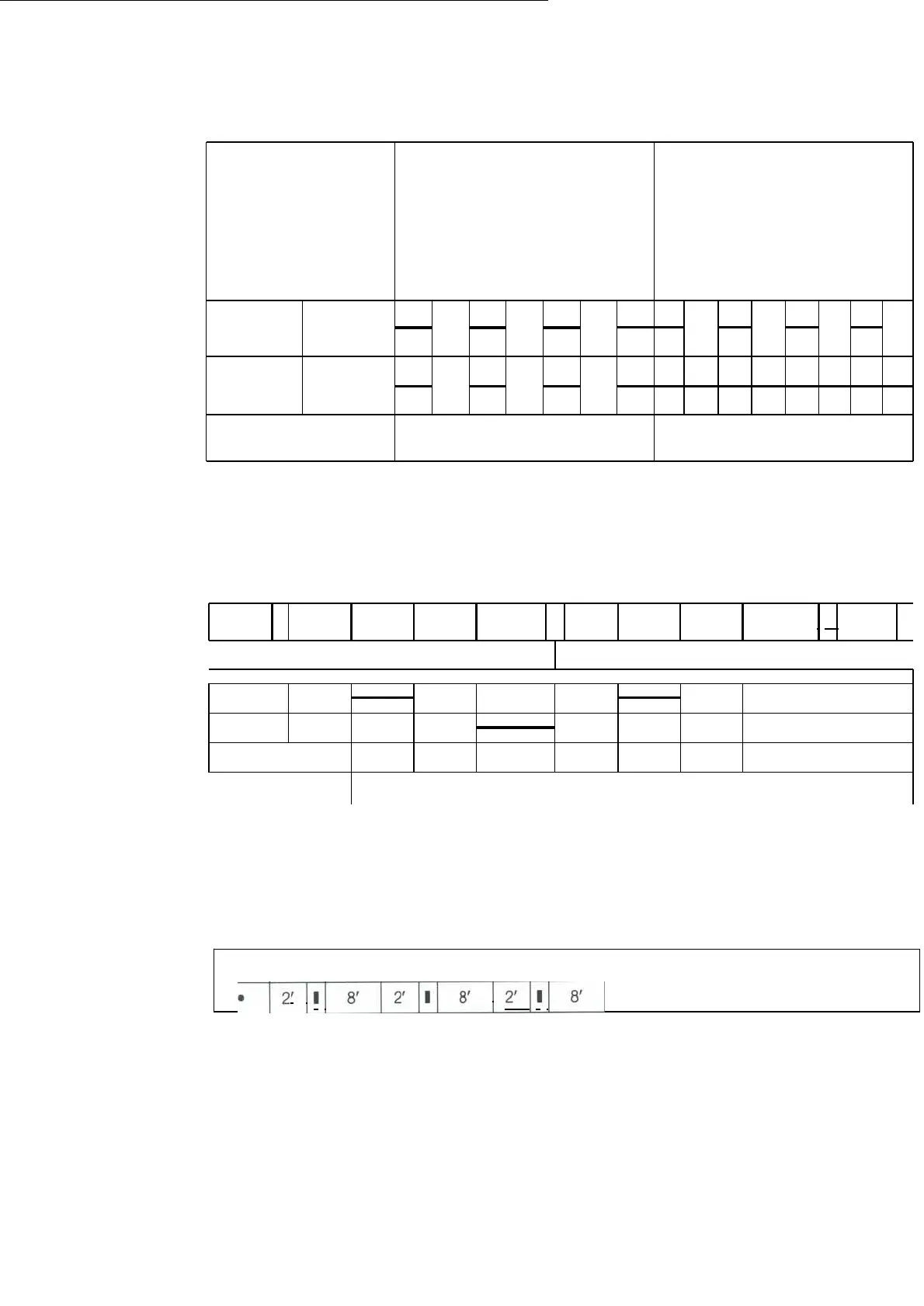

PROGRESS CHART ON WOOL SPIN

WATER CURRENTS TO ADJUST THE UNBALANCED LOAD

I

t is a function to prevent eccentricity of the clothes after wash by rotating pulsator C.W and C.C.W for 20

seconds.

EFFECT

I

t

reduces vibration and noise effectively while spinning.

WATER FLAW

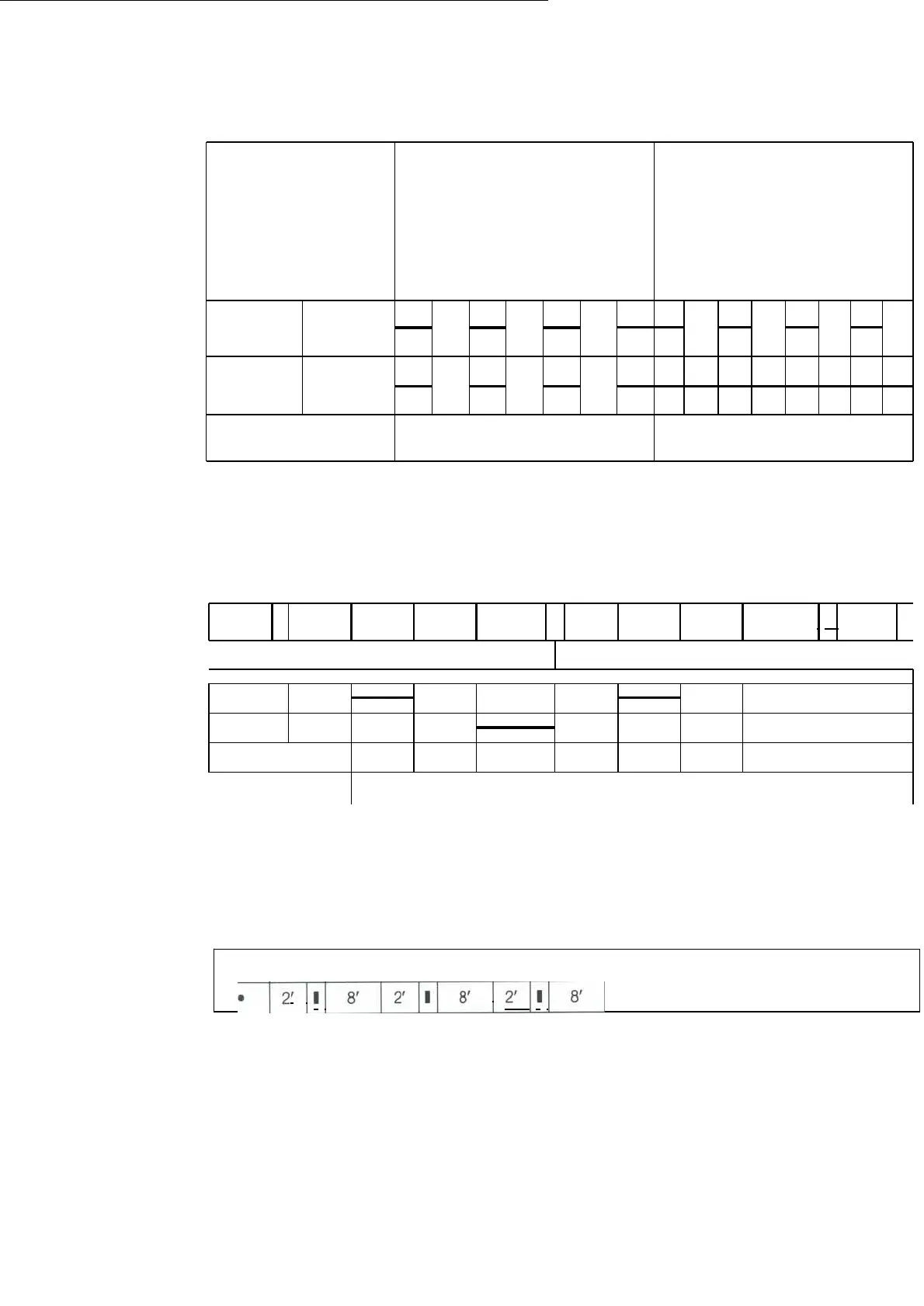

FUNCTION FOR SOAK WASH

DISPLAY THE RESIDUAL TIME

When the SOAK WASH is selected, the total wash time increases because 30 minutes for soak process

are added to the time of main process.

PROGRESS

SOAK PROCESS

MAIN PROCESS

FILL

WASH STOP WASH STOP WASH STOP

2

'

1

1

I

8'

8'

.

2/ 1

1

~

8'

30 Minutes

NOTE: `1' mark indicates the operation of the water currents to adjust the unbalanced load.

4

R.P.M.

-NORMAL

ON-OFF

DRY/SILK

4

5

2

5

5

2

E

OF

MOTOR

NORMAL

4

3

4

3

BEENE

(

SEC.)

BALANCE SPIN

NORMAL SPIN

WASH

1

DRAIN

SPIN

FILL

RINSE 1

1

DRAIN SPIN

FILL

RINSE 2

1

11

DRAIN

MOTOR

C.W

SIGNAL

C.C.W

TIME (SEC.)

0.3

0.5 0.3

0.5

0.3 0.5

20 SEC. (About 25 Times)

Loading...

Loading...