HYDRAULIC LINE INSTALLATION

1. For a metal tube to hose installation, install the tube

and tighten all bolts finger tight.

2. Tighten the bolts at the rigid end.

3. Install the hose and tighten all bolts finger tight.

4. Put the hose in a position so that it does not make

contact with the machine or another hose.

5. Tighten the bolts on both connections.

6. Start the engine.

7. Move the implement control levers to all positions.

8. Look at the hose during movement of the

implement. Make sure hose is not in contact with

the machine or other hoses.

9. Shut off the engine.

10. If necessary, put the hose in a new position where it

will not make contact when the implement is moved.

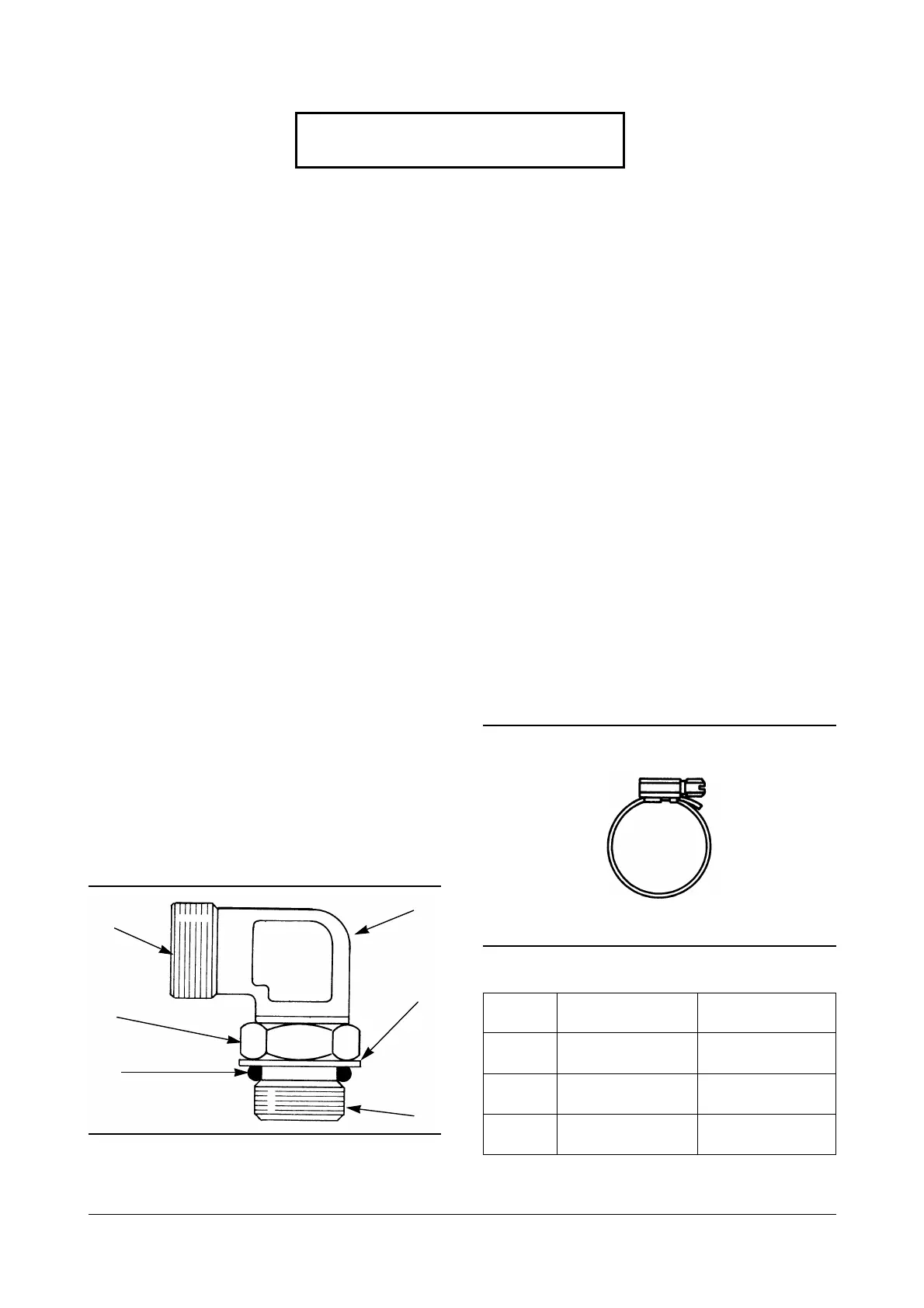

ASSEMBLY OF FITTINGS WITH STRAIGHT

THREADS AND O-RING SEALS

This type of fitting is used in many applications. The tube

end of the fitting will be different in design so that it can

be used in many different applications. However, the

installation procedure of the fitting is the same. If the tube

end of the fitting body is the same as in the illustration

(either an elbow or a straight body) it will be necessary to

assemble the sleeve on the tube before connecting the

tube to the end.

1. Put locknut (3), backup washer (4) and O-ring seal

(5) as far back on fitting body (2) as possible. Hold

these components in this position. Turn the fitting

into the part it is used on until backup washer (4) just

makes contact with the face of the part it is used on.

2. To put the fitting assembly in its correct position, turn

the fitting body (2) out (counterclockwise) a

maximum of 359

û

. Tighten locknut (3) to the torque

shown in the correct chart for the fitting used.

NOTE: If the fitting is a connector (straight fitting), the

hex on the body takes the place of the locknut. To

install this type fitting, tighten the hex against the face

of the part it goes into.

TORQUES FOR FLARED AND O-RING FITTINGS

The torques shown in the charts that follow are to be

used on the nut part of 37

û

Flared, 45

û

Flared and

Inverted Flared fittings (when used with steel tubing),

O-ring plugs, O-ring fittings and swivel nuts when

used in applications to 3000 psi (20 700 kPa).

HOSE CLAMP-BAND TYPE

4 of 7

FITTING INSTALLATION

5

3

1

2

4

6

(1) End of fitting body (connects to tube). (2) Fitting body.

(3) Lock-nut. (4) Backup washer. (5) O-ring seal. (6) End of fitting

that goes into other part.

ELBOW BODY ASSEMBLY

IDAS002B

IDAS003B

CLAMP

WIDTH

7.9 mm

(.312 in)

13.5 mm

(.531 in)

15.9 mm

(.625 in)

TORQUE ON

NEW HOSE

0.9

± 0.2 N

i

m

8

± 2 lb

i

in

4.5

± 0.5 N

i

m

40

± 5 lb

i

in

7.5

± 0.5 N

i

m

65

± 5 lb

i

in

RETIGHTENING

TORQUE

0.7

± 0.2 N

i

m

6

± 2 lb

i

in

3.0

± 0.5 N

i

m

25

± 5 lb

i

in

4.5

± 0.5 N

i

m

40

± 5 lb

i

in

Loading...

Loading...