1) Warm-up engine till coolant temperature is up to

75

c

.

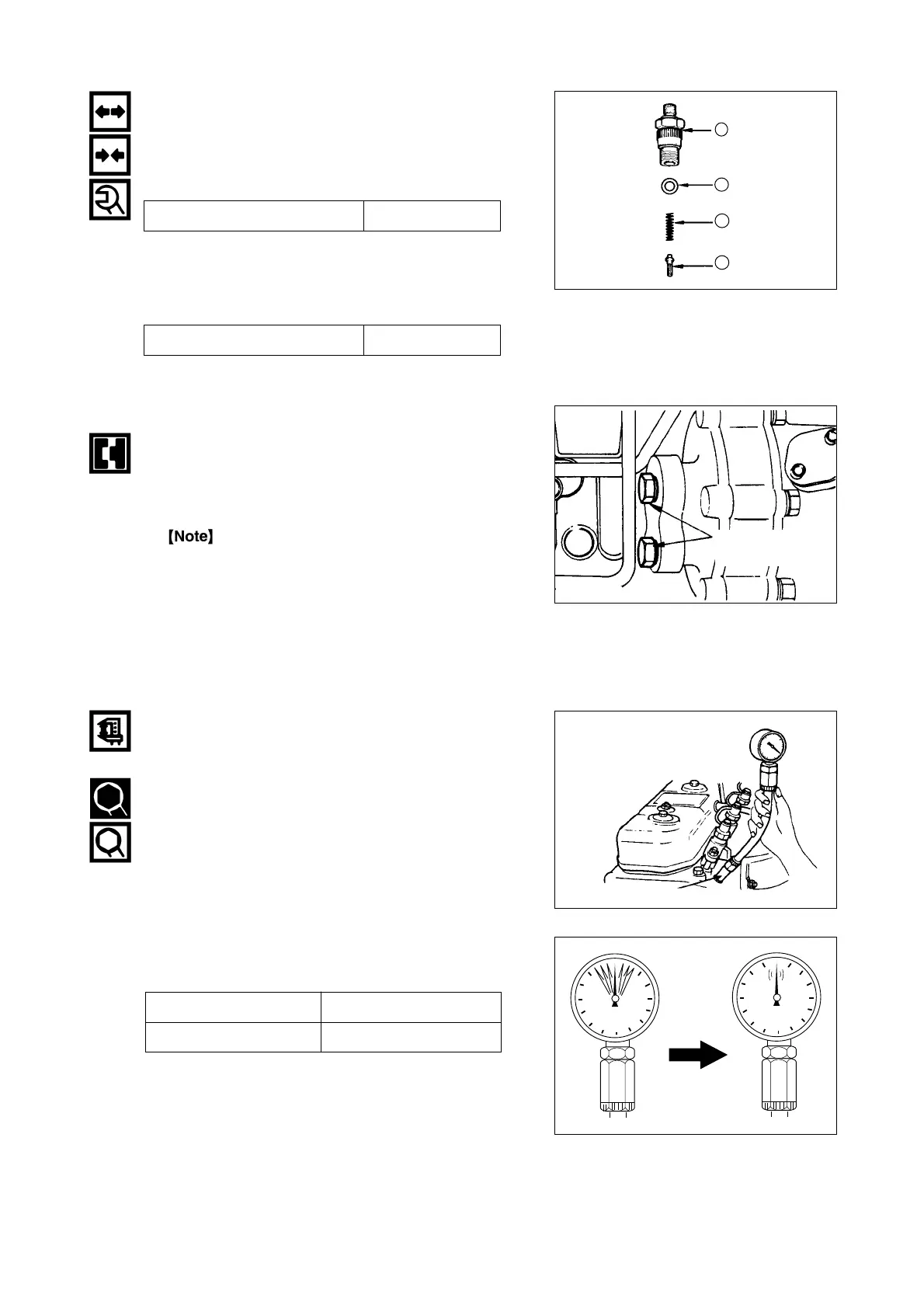

2) Remove the preheating plug and injection pipe.

3) Assemble the compression gauge at the position of

preheating plug and injection pipe.

4) Read the calibration of compressed gauge as

rotating engine with start motor.

Standard Limit

31.0 kg/cm

2

(at 200 rpm) 26.0 kg/cm

2

(at 200 rpm)

5) Practice other cylinder as same sequence.

Every compression pressure should be alike.

Allowable Inequality of compression is 2.0 kg/cm

2

.

If more, check related parts and replace it.

EJM1046S

EJM1047S

1.5.11. Compression Pressure Measurement

- 22 -

¥ Adjusting Procedure

1) Release injection pump mounting nuts.

2) To advance injection timing, rotate injection pump

for injection pump notch line to be toward below.

To retard the injection timing, rotate injection pump

in reverse direction.

When rotating injection pump by 1mm,

injection timing differ about 2˚.

3) Fix the injection pump mounting nuts.

EJM1045S

9) Remove delivery valve holder from #1 plunger.

10) Assemble the delivery valve intenal parts at the

devilvery valve holder.

11) Assemble the delivery valve holder assembly to

#1 plunger and tighten with the specified torque.

12) Assemble the #1 cylinder injection pipe and

tighten with the specified torque.

EJM1041S

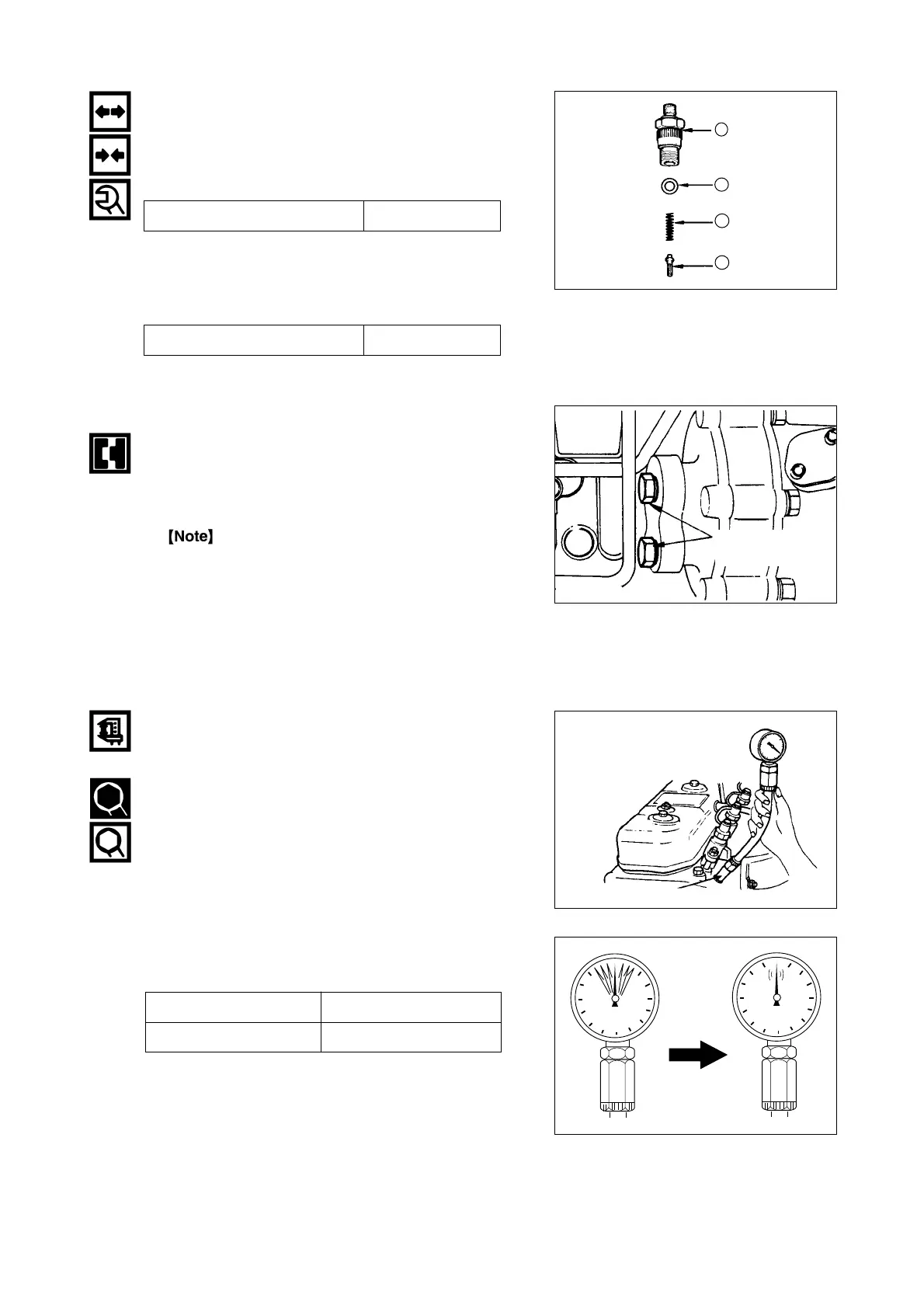

Delivery Valve Holder Torque 4.25

L

0.25 kg¥ m

Injection Pipe Nut Torque 3.1

L

0.2 kg¥ m

Holder

Seat

Spring

Delivery Valve

mounting nuts

2

1

3

4

Loading...

Loading...