- 52 -

¥

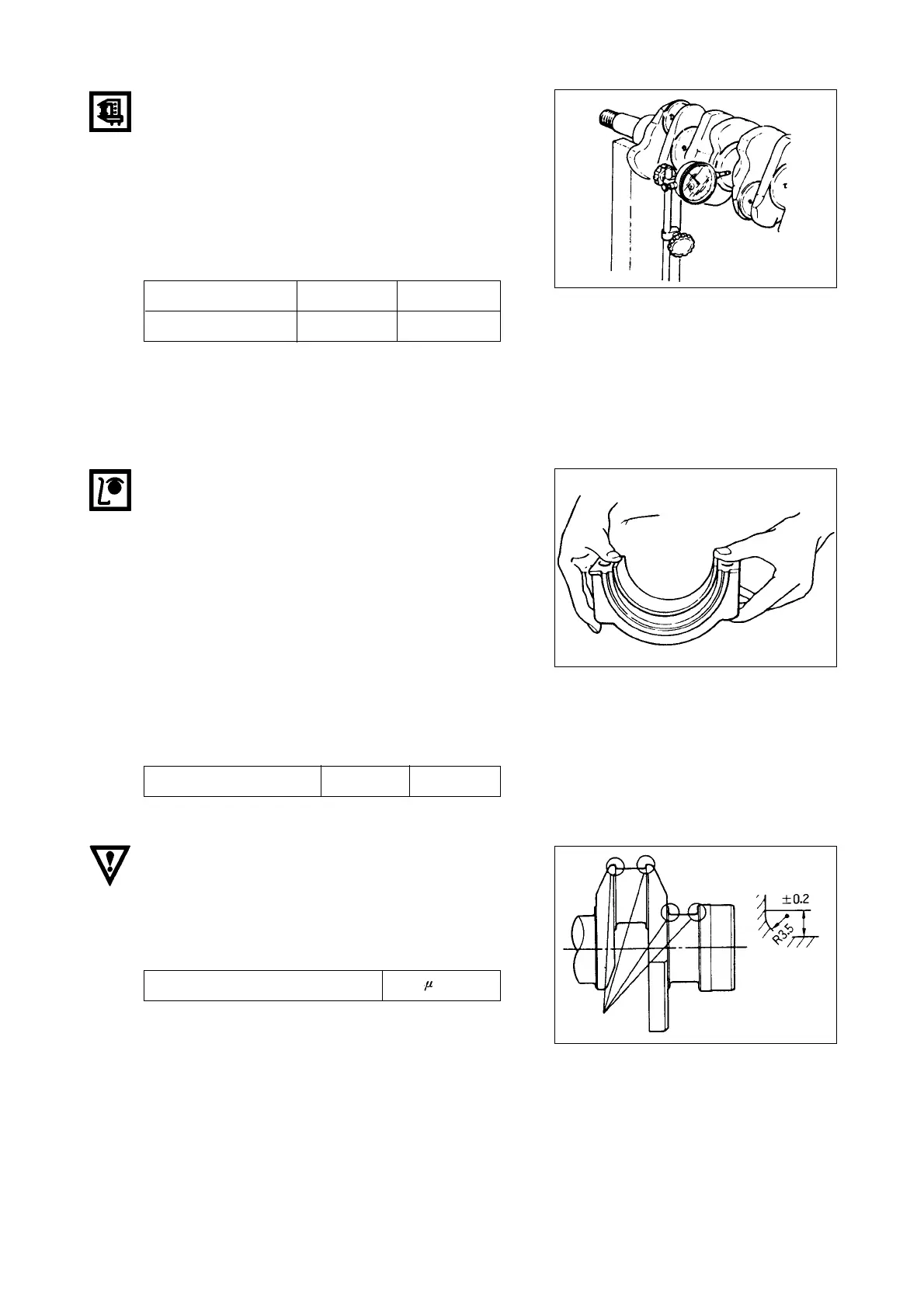

Crankshaft Run-Out

1) Mount the crankshaft on a set of V-blocks.

2) Set up the dial indicator to the center of crankshaft

journal.

3) Slowly rotate the crank shaft.

Read the dial indicator (TIR) as you turn the

crankshaft.

Replace the crank shaft if the crank shaft

measured value is out of the specified limit.

Check the repaired crank shaft after repaired, and

replace it if any damaged or cracked part is found.

¥

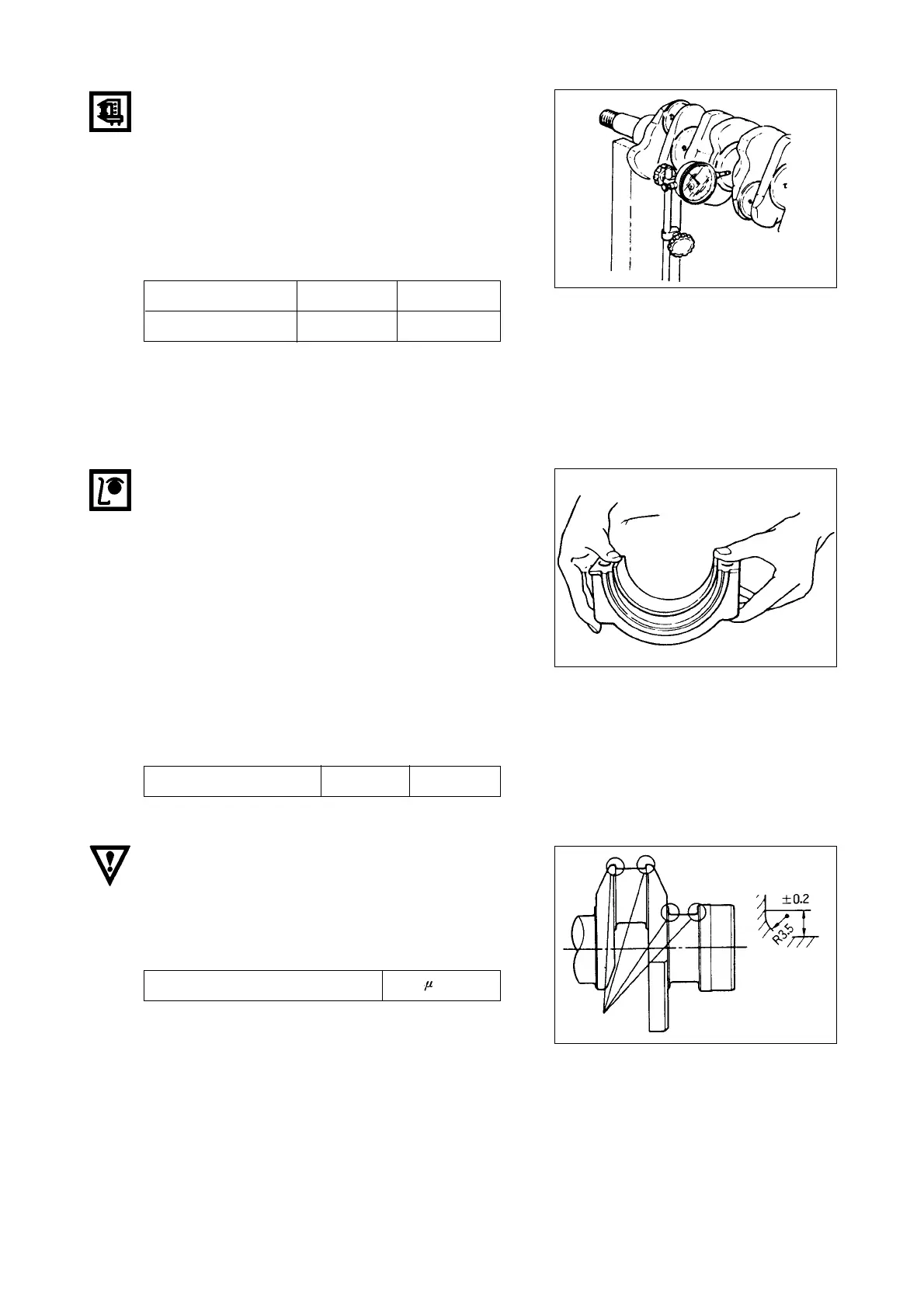

Main Bearing and Connecting Rod Bearing

Tension

Check main bearing to be maintained tension enough,

and set up its regular position with the finger

pressure.

¥

Crankshaft Grinding

Pay attention the below described in order to reuse

the regrinded crank shaft.

¥

Procedure of Crankshaft grinding

1) Grind the crank shaft journal part and pin part.

2) Grind "R" part of journl and pin to meet min R3.5 ±

0.2.

3) Make journal, pin and oil hole with R1, and finish it

with soft cotton.

4) Measure the size of jounal, pin, main bearing, con-

rod bearing.

5) Measure the crank shaft run-out.

EJM2095S

EJM2091S

EJM2096S

Standard Limit

Crankshaft Run-Out 0.05 mm 0.40 mm

Undersize Bearing 0.25 mm 0.50 mm

Journal and Pin Roughness 0.4 or less

R Part

less then 3.8

Loading...

Loading...