Maintenance Section

-129-

Torque Specifications

Metric Hardware

Most of the nuts, bolts, studs, and threaded holes in

your lift truck are metric. In this manual we provide

specifications in both metric and U.S. customary

measurement. Always replace metric hardware with

metric hardware. See the parts books for proper

replacement.

NOTE: For proper fit, use only metric tools on

metric hardware. Non-metric tools might

slip and cause injury.

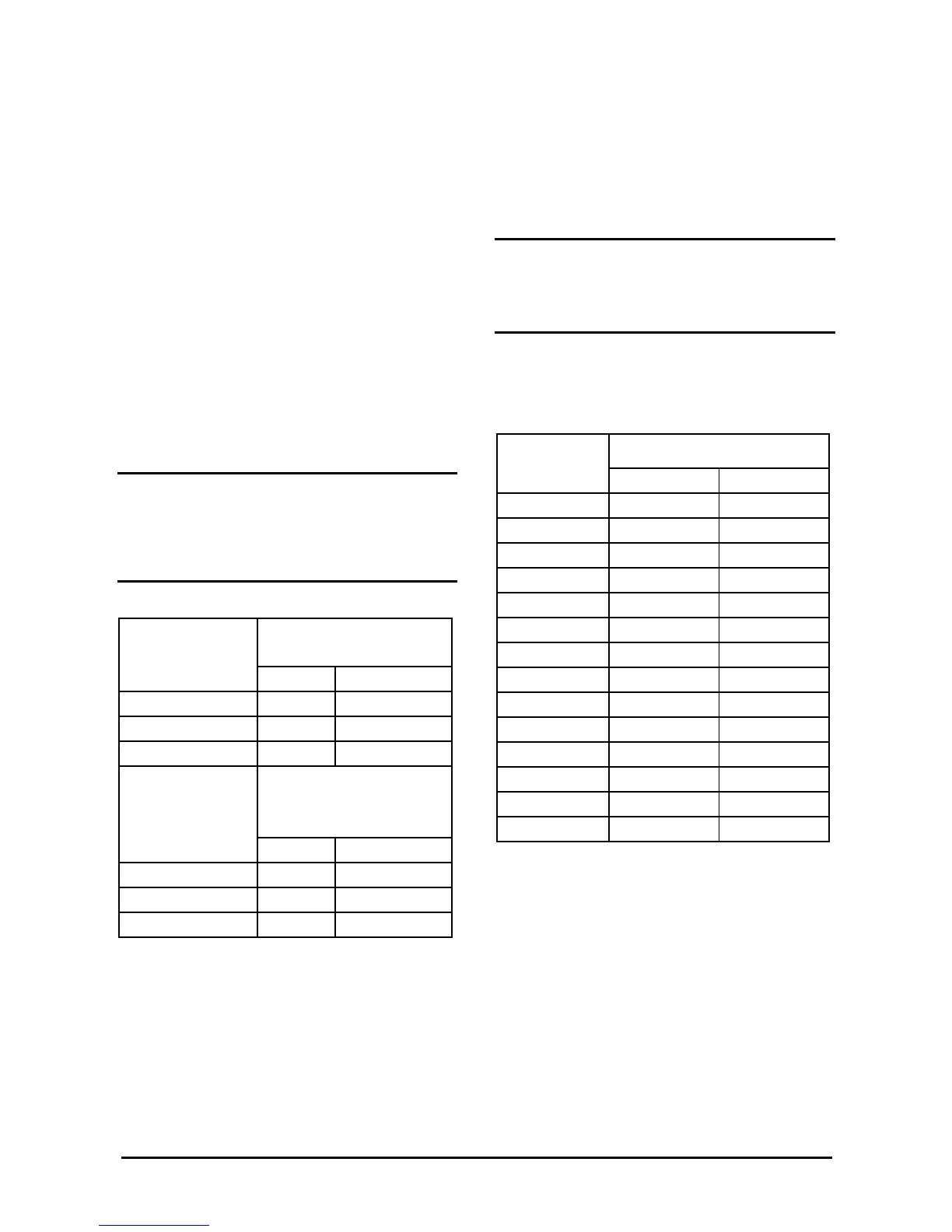

Torque for Standard Hose Clamps

- Worm Drive

NOTICE

The chart below gives the torques for initial

installation of hose clamps on new hose and for

reassembly or retightening of hose clamps on

existing hose.

Initial Installation

Torque On New Hose

Clamp Width

N•m

1

lb•in

16 mm (.625 in) 7.5 ± 0.5 65 ± 5

13.5 mm (.531 in) 4.5 ± 0.5 40 ± 5

8 mm (.312 in) 0.9 ± 0.2 8 ± 2

Reassembly or

Retightening

Torque On Existing Hose

Clamp Width

N•m

1

lb•in

16 mm (.625 in) 4.5 ± 0.5 40 ± 5

13.5 mm (.531 in) 3.0 ± 0.5 25 ± 5

8 mm (.312 in) 0.7 ± 0.2 6 ± 2

1

1 Newton meter (N•m) is approximately the same as 0.1 kg•m.

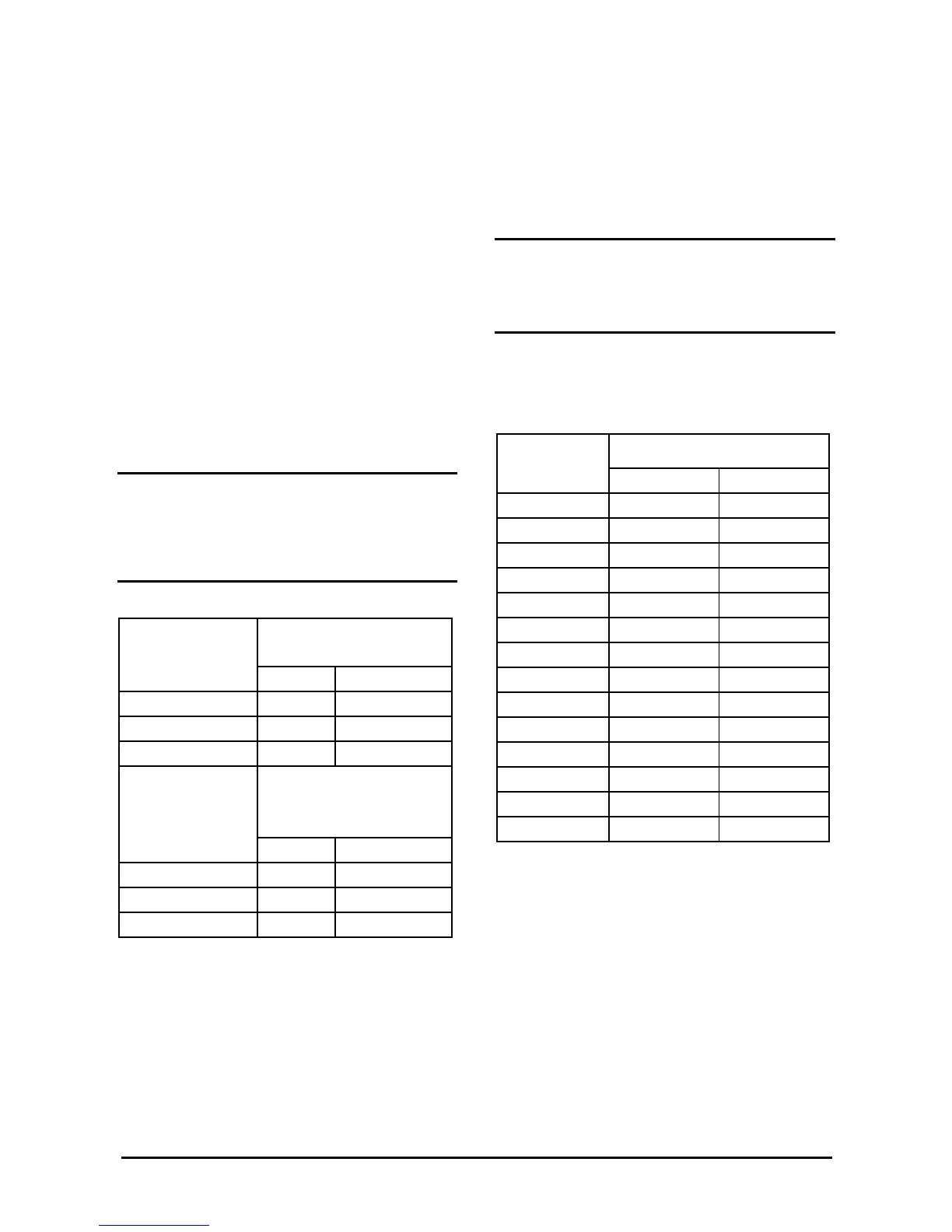

Torque for Standard Bolts, Nuts,

and Taperlock Studs

NOTICE

The two charts below give general torques for

bolts, nuts, and taperlock studs of SAE Grade 5

or better quality.

Torques for Bolts and Nuts with

Standard Threads

Standard Nut and Bolt Torque

Thread Size

Inch

N•m lb•ft

1/4 12 ± 4 9 ± 3

5/16 25 ± 7 18 ± 5

3/8 45 ± 7 33 ± 5

7/16 70 ± 15 50 ± 11

1/2 100 ± 15 75 ± 11

9/16 150 ± 20 110 ± 15

5/8 200 ± 25 150 ± 18

3/4 360 ± 50 270 ± 37

7/8 570 ± 80 420 ± 60

1 875 ± 100 640 ± 75

1 1/8 1100 ± 150 820 ± 110

1 1/4 1350 ± 175 1000 ± 130

1 3/8 1600 ± 200 1180 ± 150

1 1/2 2000 ± 275 1480 ± 200

1

1 Newton meter (N•m) is approximately the same as 0.1 kg •m.

Loading...

Loading...