14

The gas line installation must comply with local codes, or

in the absence of local codes, with the latest edition of the

National Fuel Gas Code NFPA 54 / ANSI Z223.1.

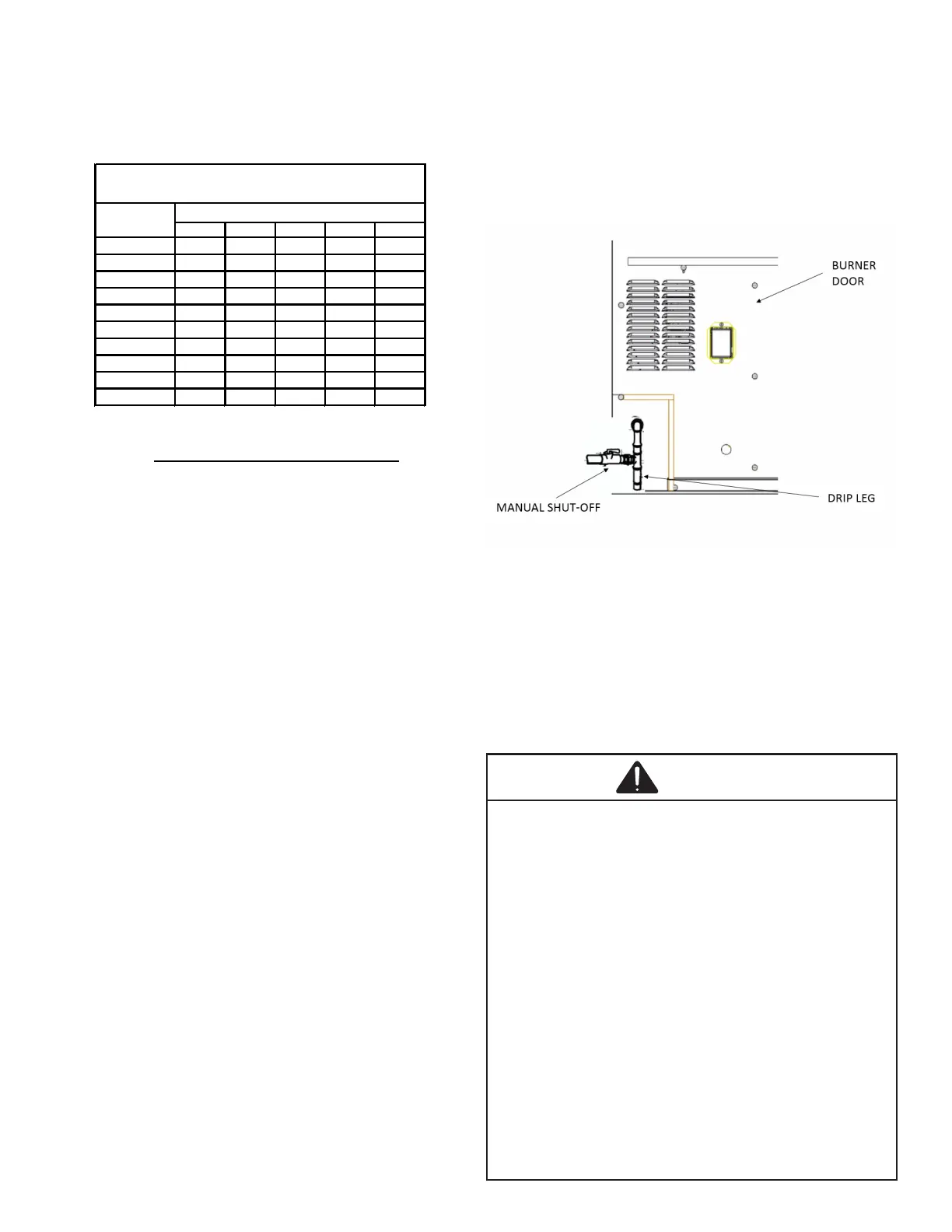

Pressure= .50 PSIG or less and Pressure Drop of 0.3" W.C.

(Based on 0.60 Specific Gravity Gas)

Nominal Black Pipe Size (inches)

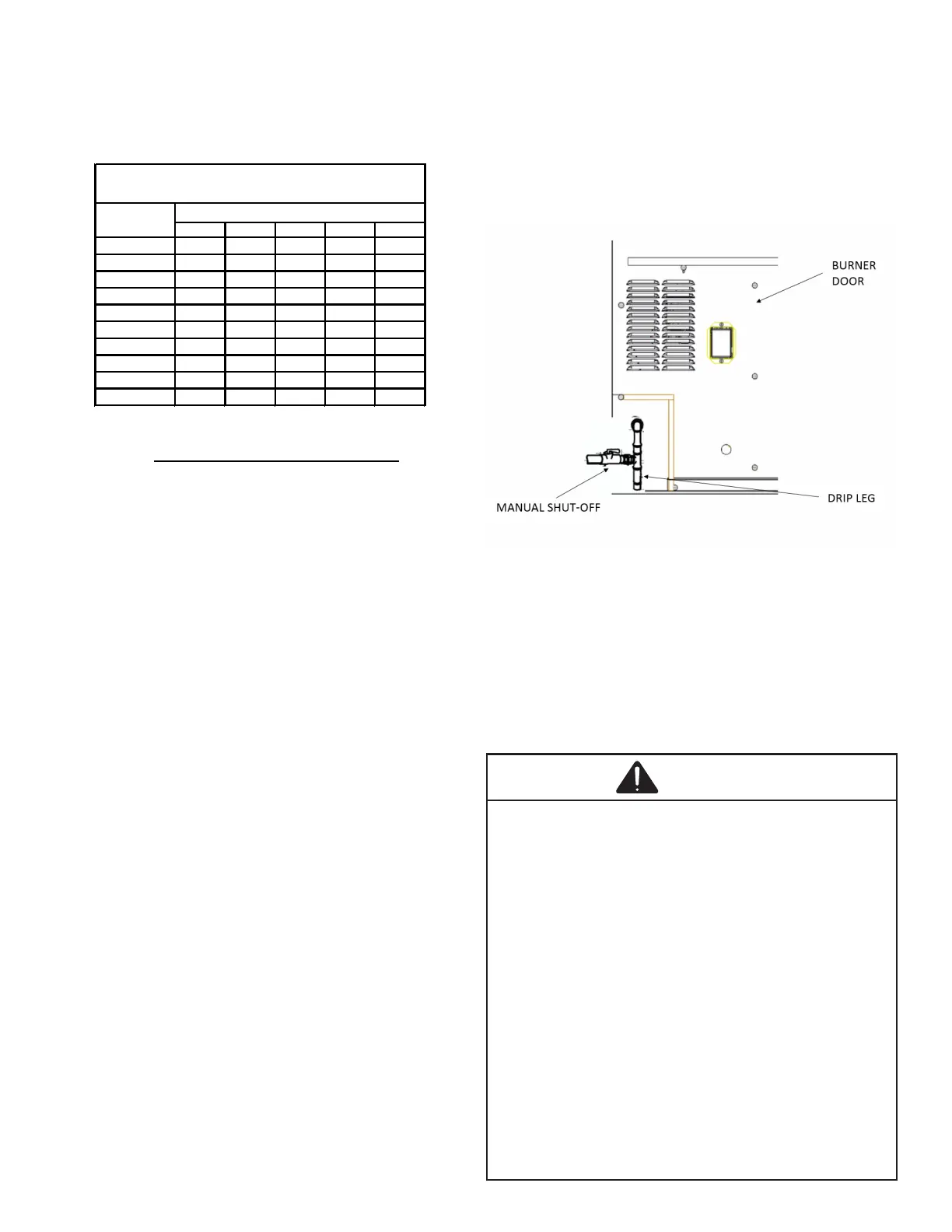

Refer to the Proper Piping Practice drawing for the general

layout at the unit. The following rules apply:

1. Use black iron pipe and ttings for the supply piping.

The use of a ex connector and/or copper piping is

permitted as long as it is in agreement with local

codes.

2. Use pipe joint compound on male threads only. Pipe

joint compound must be resistant to the action of the

fuel used.

3. Use ground joint unions.

4. Install a drip leg to trap dirt and moisture before it can

enter the gas valve. The drip leg must be a minimum

of three inches long.

5. Use two pipe wrenches when making connection to

the gas valve to keep it from turning.

6. Install a manual shut-o valve in a convenient location

(within six feet of unit) between the meter and the unit.

7. Tighten all joints securely.

8. The unit must be connected to the building piping by

one of the following methods:

• Rigid metallic pipe and ttings

• Semirigid metallic tubing and metallic ttings

(Aluminum alloy tubing must not be used in

exterior locations).

• Listed gas appliance connectors used in

accordance with the terms of their listing

that are completely in the same room as the

equipment. Always use a new listed connector.

• In the prior two methods above the connector

or tubing must be protected from physical

and thermal damage. Aluminum alloy tubing

and connectors must be coated to protect

against external corrosion when in contact with

masonry, plaster or insulation or are subject to

repeated wettings by liquids (water - not rain

water, detergents or sewage).

CAUTION

Loading...

Loading...