20

Actual RPM’s must be set and veried with a tachometer

or strobe light. Refer to Appendex A for basic unit fan

RPM. Refer also to “Airow” section of this manual. With

disconnect switch open, disconnect thermostat wires

from terminals Y and W. This will prevent heating and

mechanical cooling from coming on. Place a jumper wire

across terminals R and G at TB1 terminal block. Close

disconnect switch; evaporator fan motor will operate so

RPM can be checked.

Make preliminary check of evaporator fan ampere draw

and verify that motor nameplate amps are not exceeded. A

nal check of amp draw should be made upon completion

of air balancing of the duct system (see Appendix B).

The rst step in checking out the gas-red furnace is to test

the gas supply piping to the unit for tightness and purge the

system of air using methods outlined in the latest edition of

the National Fuel Gas Code ANSI Z223.1 / NFPA 54. Verify

that the disconnect switch is in the “OFF" position. A soapy

water solution should be used to check for gas leaks.

Since the unit is subject to considerable jarring during

shipment, it is extremely important that all gas connections

and joints be tested for tightness. Gas piping downstream

from the unit inlet should be checked for leaks during the

subsequent sequence check.

The supply gas pressure should be adjusted to 7.0” w.c.

on natural gas and 11.0” on LP gas with the gas burners

operating. If there is more than one unit on a common gas

line, the pressures should be checked with all units under

full re. A supply pressure tap is provided on the upstream

side of the gas valve. A manifold pressure tap is provided

on the manifold. The normal manifold pressure for full input

is 3.5” w.c. on natural gas and 10.0” w.c. for propane gas.

Minimum gas supply pressure is 5.5” w.c. for natural gas

and 11.0” for propane gas. In order to obtain rating, gas

supply pressure must be 11.0” w.c. for propane gas.

The pressure regulator on LP gas models is adjusted for

10.0” w.c. manifold pressure and is intended to prevent

over-ring only. Do not attempt adjustment of the built-in

pressure regulator unless the supply pressure is at least

7.0” w.c. on natural gas or 14.0” w.c. on propane gas.

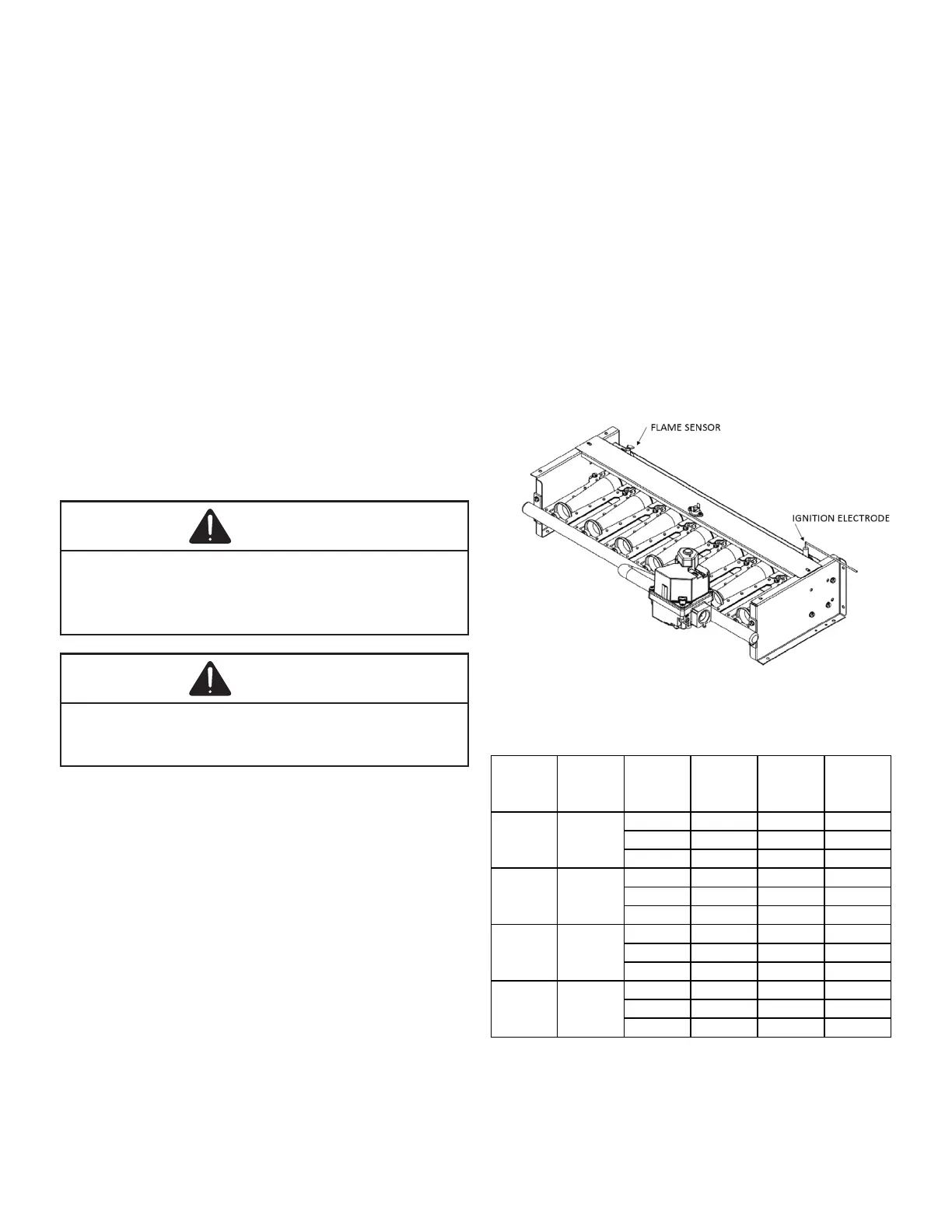

Check the location of the ignition electrode and the ame

sensor for correct gap setting.

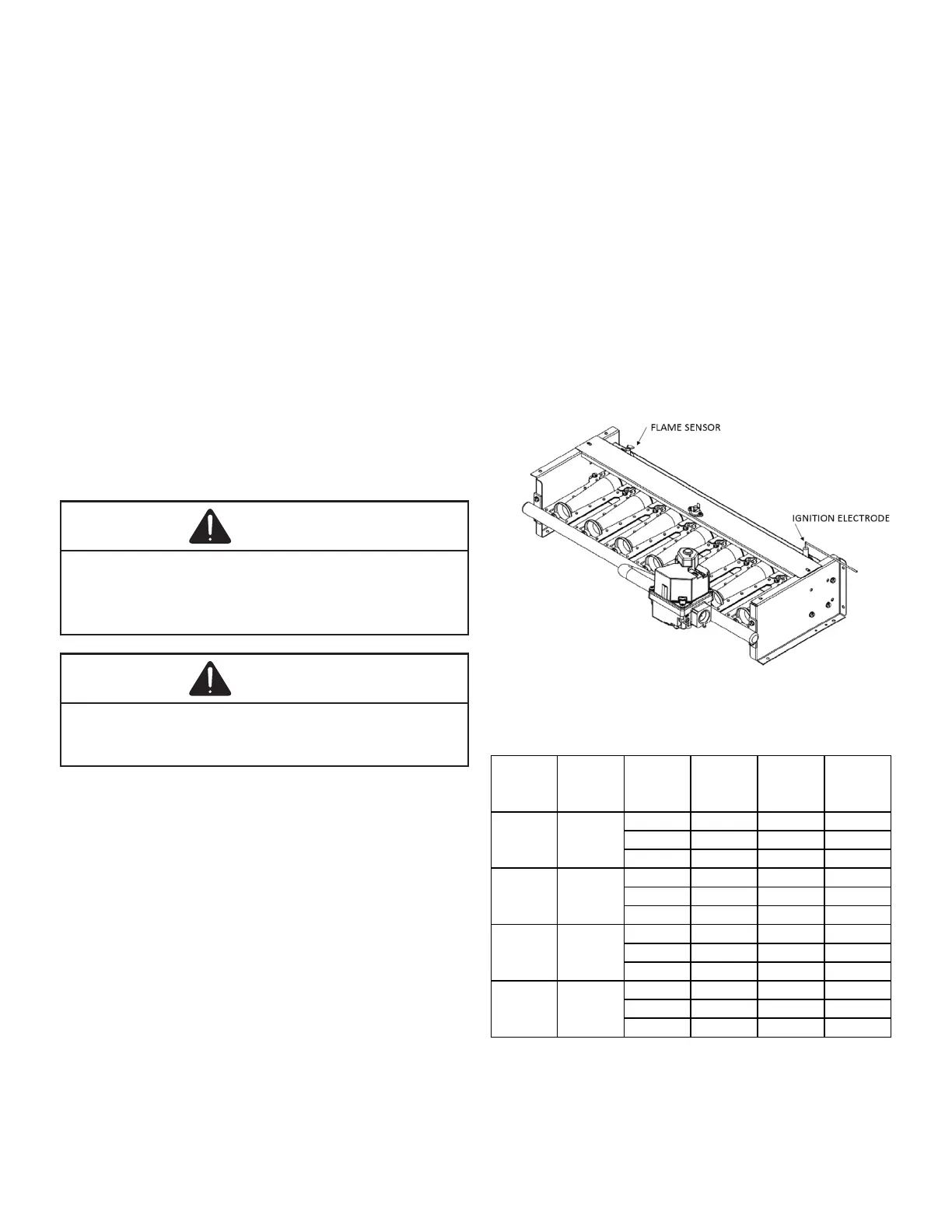

Ton Model

High Fire

Rate

Btu/Hr

No. of

Burners

N.G.

Orfice

Drill #

L.P. Orfice

Drill #

130,000 5 41 54

180,000 6 37 53

225,000 7 36 52

130,000 5 41 54

180,000 6 37 53

225,000 7 36 52

130,000 5 41 54

180,000 6 37 53

240,000 7 36 52

130,000 5 41 54

180,000 6 37 53

240,000 7 36 52

7.5

8.5

10

12.5

DFG102

DFG090

DFG120

DFG150

Loading...

Loading...