17

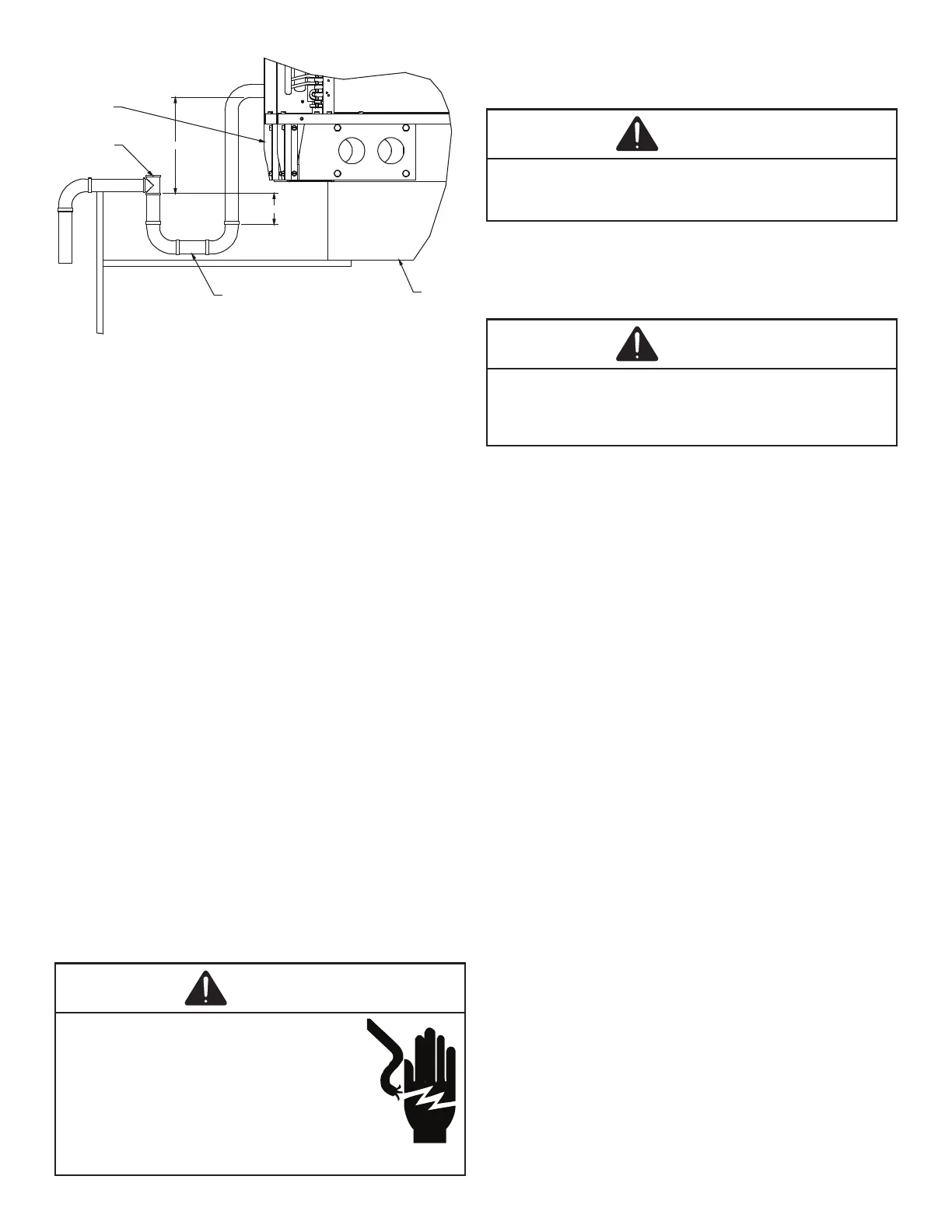

NOTE: Trap should be deep enough to offset maximum

unit static difference. A minimum 4” trap is recommended.

Drain Plug

Roof Curb

See NOTE

Base Rail

Open Vent

2” Min

Install condensate drain trap as shown. Use 3/4" drain line

and ttings or larger. Do not operate without trap.

Drainage of condensate directly onto the roof may be

acceptable; refer to local code. It is recommended that a

small drip pad of either stone, mortar, wood or metal be

provided to prevent any possible damage to the roof.

To use the bottom drain connection, remove the drain plug

from the bottom connection and install it in the horizontal

connection.

Due to the fact that the drain pans in any air conditioning

unit will have some moisture in them, algae and fungus

will grow due to airborne bacteria and spores. Periodic

cleaning is necessary to prevent the build-up from plugging

the drain.

To remove the drain pan for cleaning, remove the drain pan

cover rst (located in horizontal drain pans) then the drain

pan could be slid out.

CAUTION

Prior to the beginning of Startup, Adjustments, and Checks

procedures, the following steps should be completed in the

building.

This unit is equipped with an electronic ignition device to

automatically light the main burners. It also has a power

vent blower to exhaust combustion products.

On new installations, or if a major component has been

replaced, the operation of the unit must be checked.

Check unit operation as outlined in the following

instructions. If any sparking, odors, or unusual sounds

are encountered, shut o electrical power and recheck for

wiring errors, or obstructions in or near the blower motors.

The Startup, Adjustments, and Checks procedure provides

a step-by-step sequence which, if followed, will assure the

proper startup of the equipment in the minimum amount of

time. Air balancing of duct system is not considered part

of this procedure. However, it is an important phase of any

air conditioning system startup and should be performed

upon completion of the Startup, Adjustments, and Checks

procedure. The Startup, Adjustments, and Checks

procedure at outside ambients below 55°F should be

limited to a readiness check of the refrigeration system with

the required nal check and calibration left to be completed

when the outside ambient rises above 55°F.

If the unit is to be used for temporary heating or cooling,

a “Startup, Adjustments, and Checks" must rst be

performed in accordance with this manual. Damage or

repairs due to failure to comply with these requirements

are not covered under the warranty. the machines

are used for temporary heating or cooling, inspect the coils,

fans, and motors for unacceptable levels of construction

dust and dirt and install new lters.

Loading...

Loading...