72

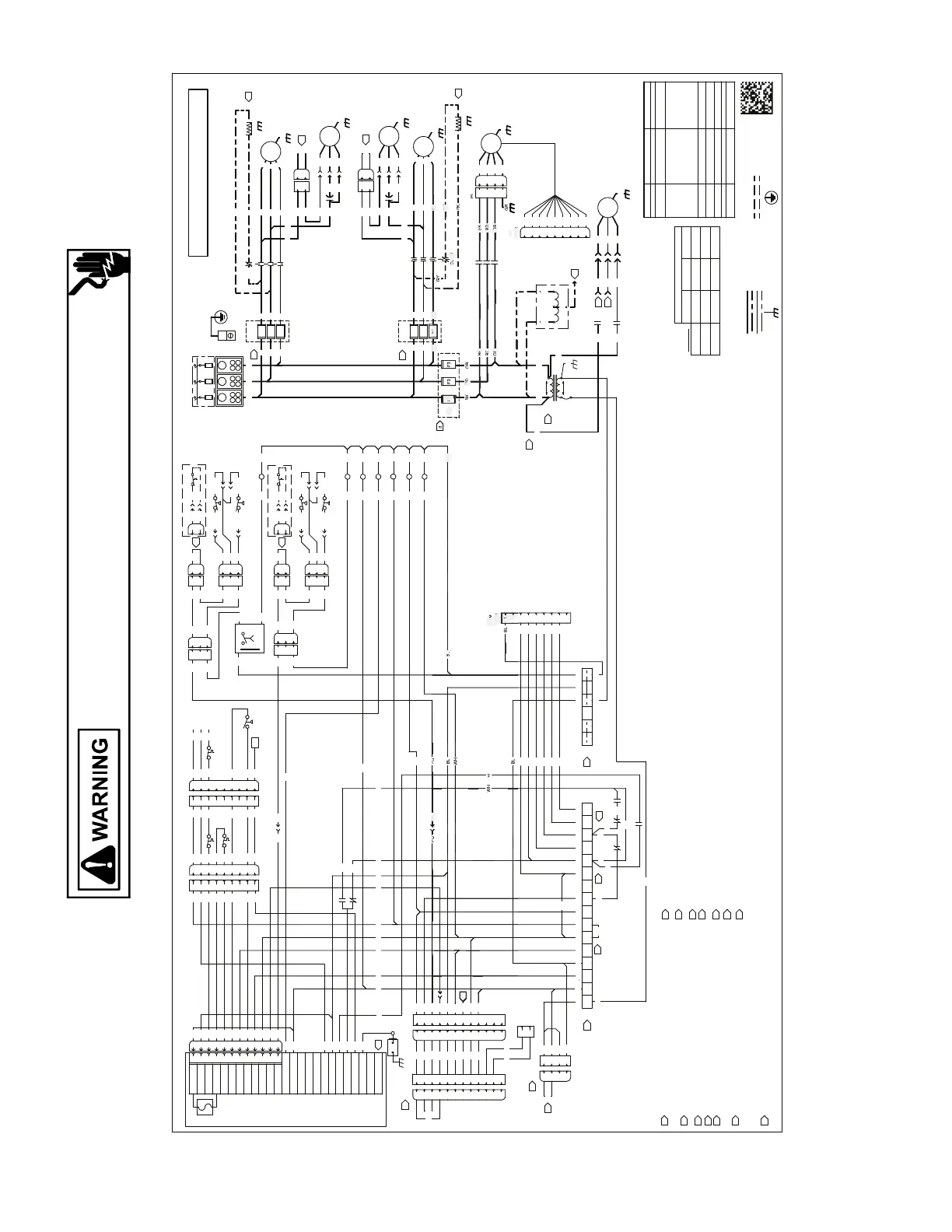

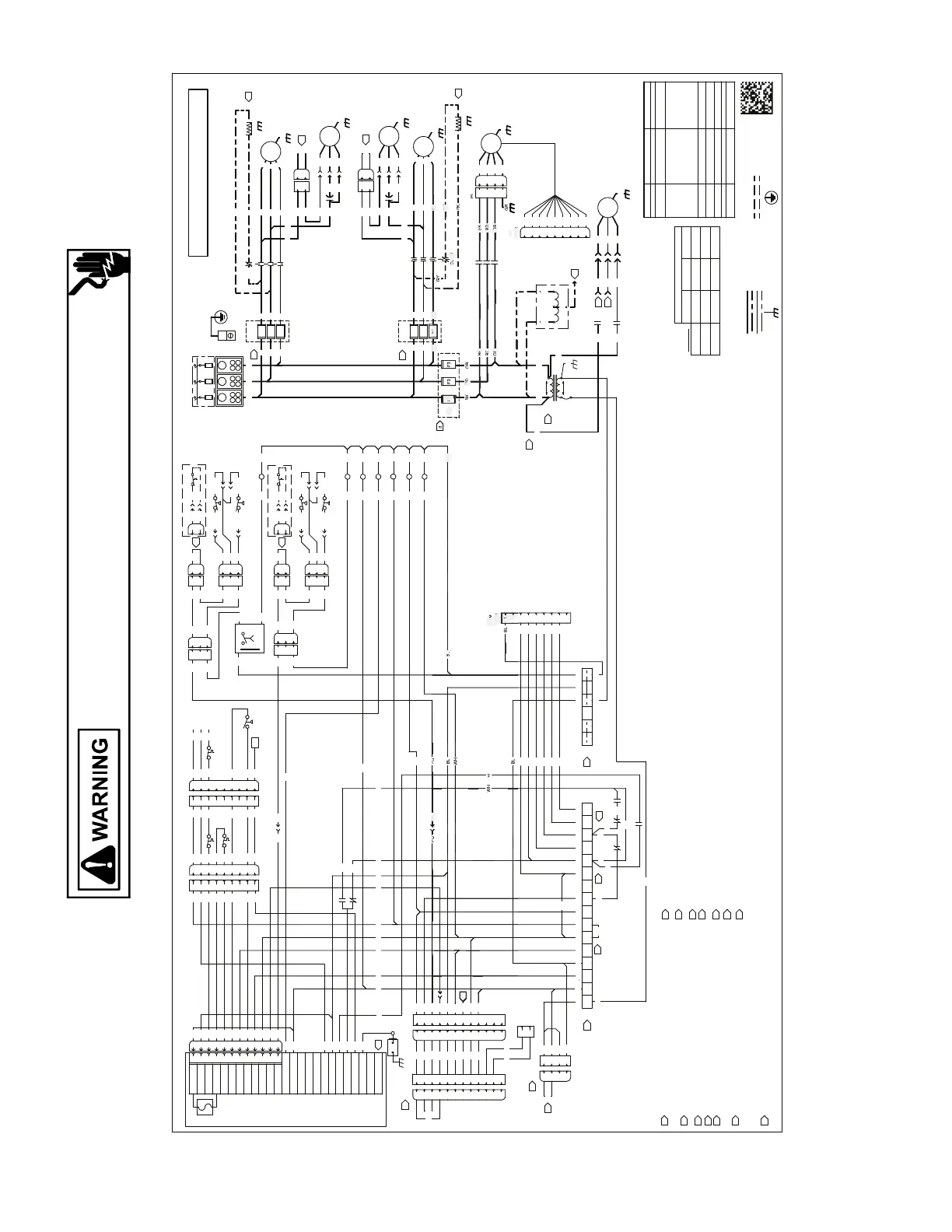

Wiring is subject to change. Always refer to the wiring diagram on the unit for the most up-to-date wiring.

0140L07382-B1

HIGH VOLTAGE

OPTIONAL HIGH VOLTAGE

LOW VOLTAGE

OPTIONAL LOW VOLTAGE

CHASSIS GROUND

REPLACEMENT WIRE MUST BE SAME SIZE AND TYPE OF INSULATION AS ORIGINAL (AT

LEAST 105° C). USE COPPER CONDUCTORS ONLY.

USE N.E.C. CLASS 2 WIRE FOR ALL LOW VOLTAGE FIELD CONNECTIONS.

IF OPTIONAL ECONOMIZER IS INSTALLED REMOVE ECON PLM JUMPER AND PLUG IN

NEW HARNESS FROM ECONOMIZER KIT

FUSE BLOCK ARE OPTIONAL

REFER TO TABLE FOR VENT MOTOR WIRING INSTRUCTIONS

TR1 PRIMARY (HIGH VOLTAGE) CONNECTIONS: ORANGE WIRE CONNECTED TO

240/460/575V TAP AT THE FACTORY AND BLACK WIRE TO COM TERMINAL.

FOR 208V SUPPLY POWER, MOVE ORANGE WIRE FROM 240V TAP TO THE 208V TAP.

IF OPTIONAL OEM SAFETY EQUIPMENT SUCH AS A PHASE MONITOR, FLOAT SWITCH

OR SMOKE DET ECTOR IS INSTALLED, UNPLUG JUMPER PLUG AND PLUG IN SAFETY

DEVICE.

IF MULTIPLE SAFETIES ARE INSTALLED, PLUG IN THE ADDITIONAL DEVICES IN SERIES.

PLUG IN JUMPER PLUG AT THE LAST SAFETY DEVICE INSTALLED.

IF A THIRD PARTY SAFETY DEVICE IS FIELD INSTALLED, CUT WIRE ON THE JUMPER

PLUG AND W IRE IT IN SERIES WITH THE SAFETY CIRCUIT.

L1PB L2 L3

GND

BLRD

BK OR

BK BK

BK

COMPONENT LEGEND

WIRE CODE

FACTORY WIRING

HIGH VOLTAGE

LOW VOLTAGE

EARTH GROUND

NOTES

1

1

2

3

4

5

6

7

8

9

10

11

12

24V

COM

GV

LMT OUT

LMT IN

PS IN

G

PS OUT

R

W

COMP IN

COMP OUT

D1

L1

L1

L2

L2

L2

L2

COOL FAN

HEAT FAN

FS

IGN

SPEED - UP

UNUSED

3A

PCB

IIC

1

2

3

4

5

6

7

8

9

10

11

12

PLM2 PLF2

ECON

12

1

2

4

5

3

6

7

8

9

10

11

12

1

2

7

4

3

6

5

8

11

10

9

R2 R1

t = 180s

Y2 Y1

TON2

CC1

A1 A2

YL BL

CC2

A1 A2

PU BL

BC

A1 A2

PK BL

VMC

A1 A2

WH BL

BR2

10

YL BL

BR3

10

WH BL

ALS AUXILIARY LIMIT SWITCH

BC BLOWER CONTACTOR

BM BLOWER MOTOR

BR BLOWER RELAY

CB CIRCUIT BREAKER

CC COMPRESSOR CONTACTOR

CCH CRANKCASE HEATER

CCX COMPRESSOR CONTACTOR AUXILIARY

CM CONDENSER MOTOR

COMP COMPRESSOR

ECON ECONOMIZER

ES EMERGENCY SHUTDOWN

FB FUSE BLOCK

FC FAN CAPACITOR

FPS FREEZE PROTECTION SWITCH

FS FLAME SENSOR

GND EQUIPMENT GROUND

GV GAS VALVE

HPS HIGH PRESSURE SWITCH

IIC INTEGRATED IGNITION CONTROL

LPS LOW PRESSURE SWITCH

LS LIMIT SWITCH

MAT MIXED AIR TEMPERATURE SENSOR

PB POWER DISTRIBUTION BLOCK

PLF FEMALE PLUG/CONNECTOR

PLM MALE PLUG/CONNECTOR

PS PRESSURE SWITCH

RS ROLLOUT SW ITCH

TB TERMINAL BLOCK

TON TIME DELAY RELAY (ON)

TR TRANSFORMER

VM VENT MOTOR

VMC VENT MOTOR CONTACTOR

FIELD WIRING

PK

BL

PU

RD

RD

YL

GR

YL

RD

WH

YL

YL

WH

PK

BL

BL

YL

TN

RD

OR

POWER AND CONTROLS WIRING DIAGRAM

DFG 090 - 150 DIRECT DRIVE

LINE VOLTAGE:

208-230/460/575V/3PH/60HZ

PU

WH

YL

GR WH YL

PU

BL

BK BLACK

BL BLUE

BL/PK BLUE WITH PINK STRIPE

BR BROWN

GR GREEN

GY GRAY

OR ORANGE

PK PINK

PU PURPLE

RD RED

TN TAN

WH WHITE

YL YELLOW

YL/PK YELLOW WITH PINK STRIPE

PU

PU 2

1

2

1

PLF PLM

FPS 2

LPS 2

HPS 2

/YL PK /YL PK

/BL PK /BL PK

PU

PU

YL

YL

BL3

1

2

3

1

2

PLF2 PLM2

PS 2

BL

YL

YL 2

1

2

1

PLF PLM

FPS 1

LPS 1

HPS 1

/YL PK /YL PK

/BL PK /BL PK

YL

YL

YL

YL

BL3

1

2

3

1

2

PLF2 PLM2

PS 1

BL

GR

BM

~

M

3

GR

2PLF 2PLM

1

PLM

BM

BM

BL

RD

GY

GR

YL

PU

WH

BR

BK

4

1

2

3

4

1

2

3

9

1

2

7

4

3

6

5

8

BK

RD

OR

GR

L2 T2

BC

RD

RD RD

L2 T2

OR OR

L3 T3

2

3

4

5

6A

7

8

6B

FS

PS

BR

BL

RD

FB3

F3

F3 F3

3

3

3

9

6A

AB C DTB2S1 S2 R C G W1 W2 Y1 Y2 O DH T1 T2 T3 T4 T5TB1

PLF1

BM

BL

GY

GR

YL

PU

WH

BR

BLBLBRWHPUYLGYYLWHGRRDRD

RD

BL

9

1

2

4

5

3

6

7

8

ES

PLFPLM

4

1

2

3

4

1

2

3

RD

PK

RD

RD

PU

PU

8

GR BL

BL

BL

WH

7

9

1

2

7

4

3

6

5

8

GAS

PLM1

BLPU

BR

PK

PK

RD

BL

BL

BK ORRD

OR

BR

GR

WH

BR1

10

BR BL

TROUBLESHOOTING THI S APPLIANCE. STATUS LIGHT CODES ARE AS FOLLOWS:

THE STATUS LIGHT ON THE FURNACE CONTROL MAY BE USED AS A GUIDE TO

FALSE FLAME SENSED

OPEN LIMIT SWITCH

PRESSURE SW ITCH CLOSED

WITHOUT INDUCER ON

PRESSURE SW ITCH

NORMAL OPERATION

CHECK INPUT POW ER

CHECK FUSE CONTROL

3 BLINKS

6 BLINKS

4 BLINKS

5 BLINKS

COMPRESSOR OUTPUT DE LAY

OFF

ON

1 BLINK

2 BLINKS

STATUS LIGHT

OPEN AUX. LIMIT

IGNITION FAILURE

OPEN ROLLOUT

SWITCH

OPEN

SWITCH

NO POWER OR INTERNAL

CONTROL

EQUIP. ST ATUS

CHECK

ANTI-CYCLE TIMER

MAIN LIMIT O PEN

STICKING GAS VALVE

BAD SWITCH

3 MIN. COMP.

PRESSURE SW ITCH

GAS PRESSURE

FLAME ROLLOUT

AUX. LIMIT OPEN

FLAME SENSOR

BAD SWITCH

GAS VALVE

REPLACE CONTROL

GAS FLOW

PRESSURE SW ITCH

CHECK

-

CHECK

208V 230V 460/575V

VM-BK

VM-RD

VM-RD

N/A

N/A

VMC-L1 (BK)

VMC-T1

IIC-UNUSED

TR3-RD

LINE VOLTAGE

43

42

BR3

BR

PK

WH

YL

GY

78

BR3

24

BR1

87

BR2

42

BR2

WH

BL

PU

BR

WH

PU

YL

GR

GY

BL

YL

WH

YL

RD

RS

XX

BL

YL

XX

RD

RD

PU

1

2

3

4

5

6

7

8

9

RD

YL

BR

RD

RDRDRDRD

PU

BR

BL

YL

YL

RD

9

1

2

7

4

3

6

5

8

GAS

PLM2

XX

BL

YL

XX

PU

1

2

3

4

5

6

7

8

9

RD

YL

BR BR

BL

YL

YL

RD

HIGH

COM

LOW

BL

YL

RD

YL

YL

PLF1

PLF2

PLF

PLF

MAT

1

2

BK

BK

GY

PK

YL

PU

PU

YL

BL

GR

OR

2

PLM1 PLF1

ECON

12

1

2

4

5

3

6

7

8

9

10

11

12

1

2

7

4

3

6

5

8

11

10

9

GY

PK

YL

PU

PU

YL

BL

GR

WH

9

LS

ALS

WH

6B

GR WH

BL

NOTE 4:

4

VM-BK VM-BK

VM-RD

BK

RD

PU

BK

RD

OR

BK

RD

OR

GY

PK

GY

CC2

L1 T1

L2 T2

L3 T3

CCX2

GR

CCH2

GR

COMP2

L1

L2

L3

~

M

3

BK

RD

YL

BK

RD

OR

BK

RD

OR

RD

BK

CC1

L1 T1

L2 T2

L3 T3

CCX1

GR

COMP1

L1

L2

L3

~

M

3

GR

CCH1

BK

FB1

F1

F1

F1

FB2

F2

F2

F2

BK OR

GR

VM

M

~

1

4

4

WH

BK

RD

WH

L1 T1

VMC

L2 T2

4

OR

RD

TR2

150VA

BK

TR1

COM

CB

GR

OR

5

BK

BK

RD

OR

BK

4

WH

BL

FPS2

PLM

2

1

PU

PU BK

BK

PU

FPS1

PLM

2

1

YL

YL BK

BK

YL

10

10

10

11

22

33

PS1

YLYL YL

YL YL

11

22

33

PLF1

PLM1

PS2

PUPU

PUPU

PUPU

PU

11

11

11

GR

~

M

1

CM 2

FC 2

BK

BR

PU

GY

BR

PU

PK

GR

~

M

1

CM 1

FC 1

BK

BR

PU

BK

BR

PU

RD

PLF

PLM

CM

BK

BK

PLF

PLM

CM

GY

GY

GY PK

BK

RD

2

1

2

1

BK

2

1

2

1

GY

12

12

12

FOR HIGHER TORQUE, "YL" AND/OR "WH" WIRE(S) CAN BE MOVED TO T2 ON TB1.

SEE IO MANUAL FOR ADDITIONAL INFORMATION.

FOR HIGHER TORQUE, "PU" AND/OR "BR" WIRE(S) CAN BE MOVED TO T4 - T5 ON

TB1. SEE IO MANUAL FOR ADDITIONAL INFORMAT ION.

24VAC ALARM OUTPUT FROM OPTIONAL ECONOMIZER CONTROL MODULE

IF OPTIONAL FREEZESTAT IS INSTALLED, REMOVE FPS PLM JUMPER AND PLUG

IN FREEZESTAT HARNESS.

CRANKCASE HEATER IS OPTIONAL.

IF LOW AMBIENT KIT IS INSTALLED REMOVE CM PLM JUMPER AND PLUG IN NEW

HARNESS FROM LOW AMBIENT KIT.

FOR TWO STAGE HEAT OPERATION, REMOVE JUMPER BETWEEN W1 AND W2.

13

13

GV

PLF1

PLM1

1

1

BM

B

Loading...

Loading...