Operating instructions

44

Daikin RoCon

Daikin Control unit

008.1543999_00 – 03/2017 – EN

6 x Parameter settings

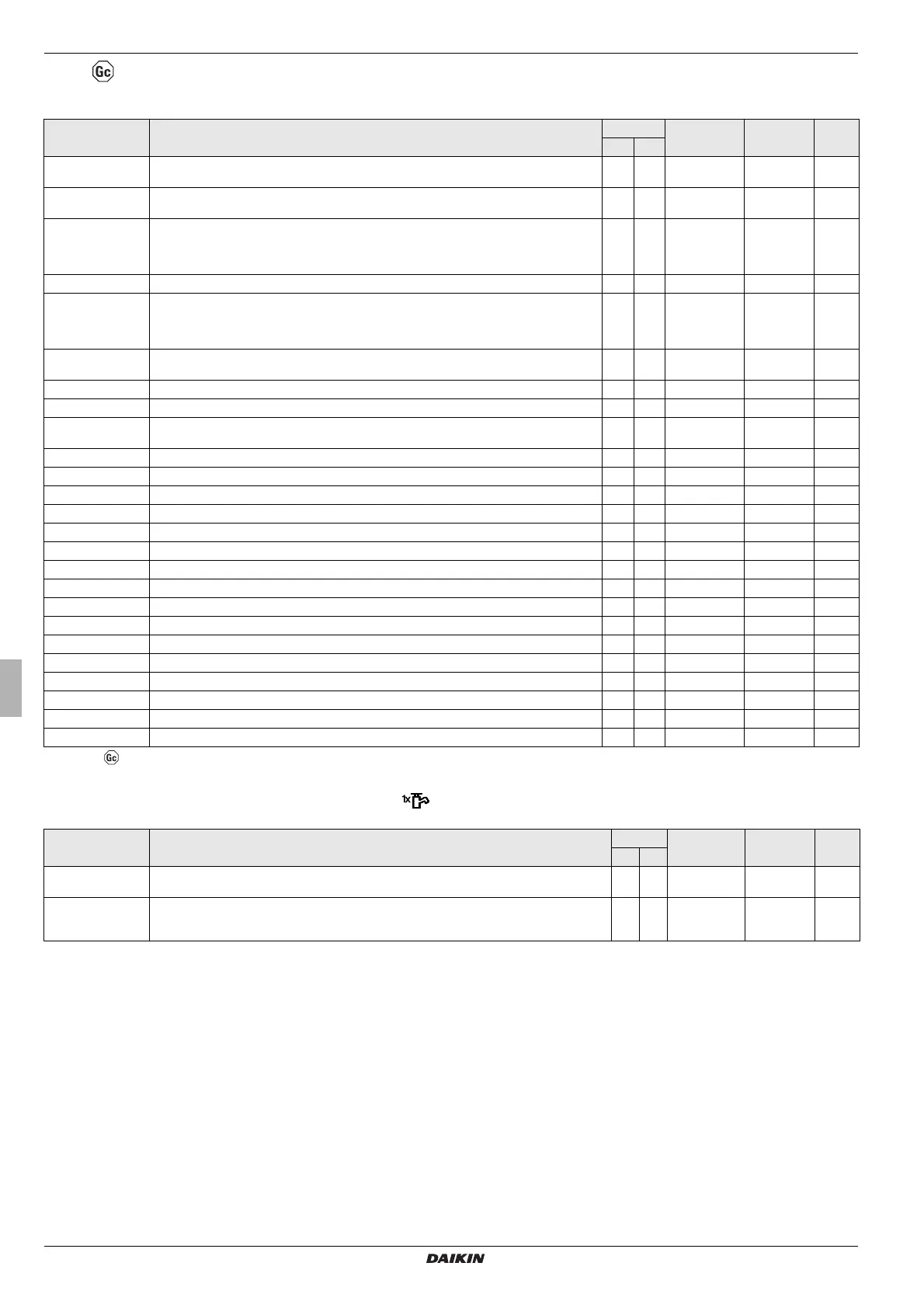

6.2.6 "Lambda-Gx" level (only for the heat generator GCU compact)

This parameter level is not displayed if the "Standby" operating mode is active.

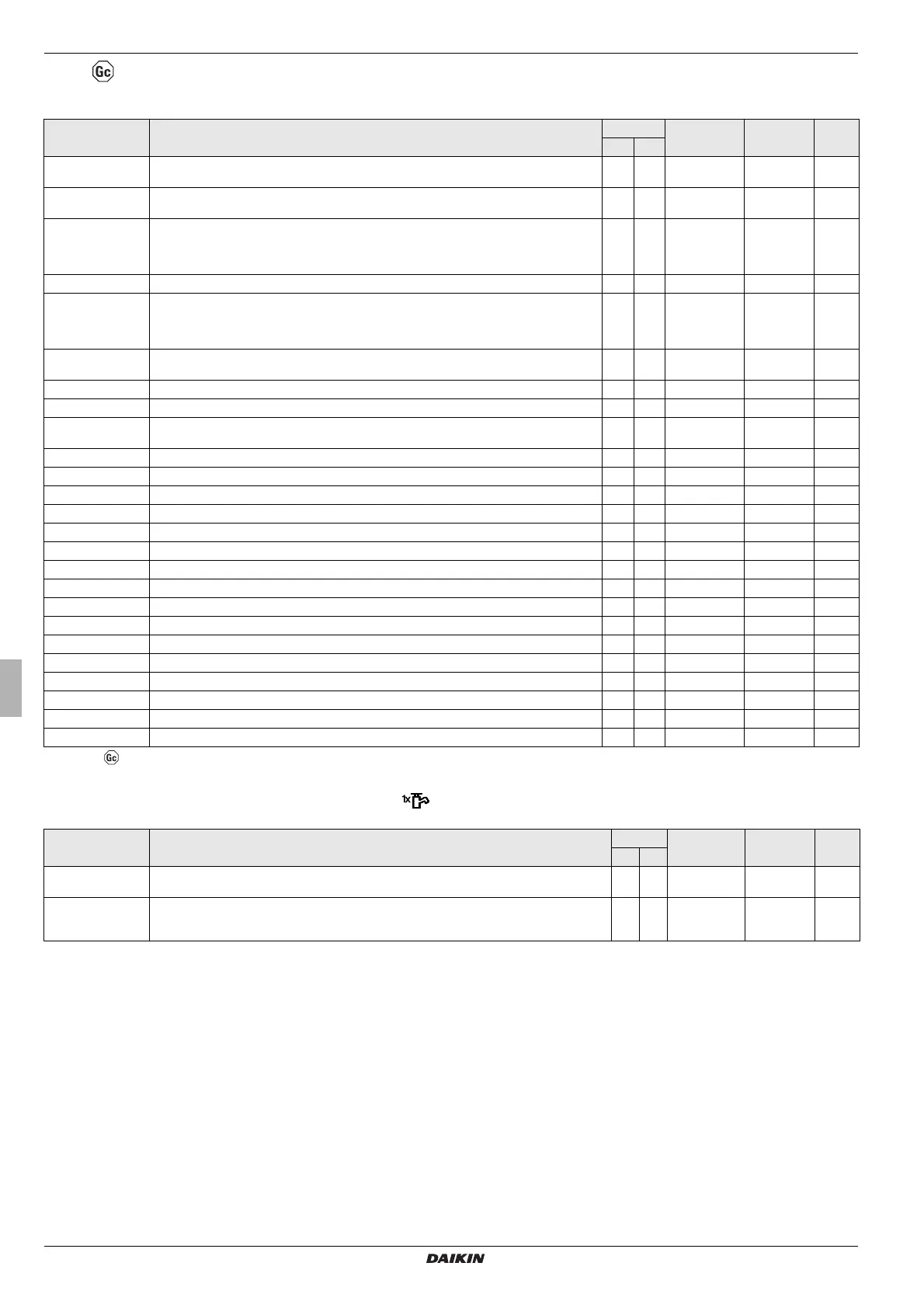

6.3 Rotary switch setting: DHW Reheating

Parameter Name Access Setting range

Min / Max

Factory

setting

Incre-

ment

BE HF

Gas type Changeover natural gas/liquid gas. For this, please observe the mechanical switchover of the

gas valve (see installation and maintenance instructions of the GCU compact).

N E Natural gas

Liquid gas

Natural gas -

Corr qGas start Correction value of the amount of gas for the ignition process. This value can be adjusted in

the case of starting problems.

N E -10 - 20 % 0 1 %

100% Calibration Off: No function

On: Manual start of the calibration. It is always necessary for a burner change or if the ionisa-

tion electrode is cleaned or replaced. The firing unit determines the new ionisation base value

by this. It takes approx. 30 - 60

s. Afterwards, the parameter value is automatically set to "Off".

N E Off

On

Off -

Corr power start Adjustment of the start power. This enables noise and start problems to be counteracted. N E -16 - 14 % 0 2 %

CL - Offset CES Adjustment of the presetting of the GAS control valve. Value only works once until the next ad-

aptation, it is then independently changed/adjusted by the controller. Adjustment can be nec-

essary if the gas fitting is being replaced and too little gas would flow into the combustion

chamber from the control valve.

N E 20 - 40 % xx.x 0.2 %

BCCRe-Update Status message, informative N E Off

On

Off -

Error Code Active error of the firing unit (see tab. 7-2). N S 0 0 -

Q-SetpointRoCon Informative - Variable process value. N S - xxx -

Q-ActualValueRo-

Con

Informative - Variable process value. N S - xxx -

T-HS Current T-HS. N S - xxx -

T-Return Current T-Return. N S - xxx -

IO-SP Informative - Variable process value. N S - xxx -

IO-AV Informative - Variable process value. N S - xxx -

ConV Informative - Variable process value. N S - xxx -

ConF Informative - Variable process value. N S - xxx -

IO-BV Informative - Variable process value. N S - xxx -

IO-CalMax Informative - Variable process value. N S - xxx -

IO-Comp Informative - Variable process value. N S - xxx -

IO-S Informative - Variable process value. N S - xxx -

FI-T Informative - Variable process value. N S - xxx -

IgtoCal Number of necessary ignitions until calibration is automatically carried out. N S - xxx -

Lerr Last error of the firing unit (see tab. 7-2). N S - xxx -

PLErr Count of how often the last error has occurred. N S - xxx -

Burner Starts Sum of all starts that are stored in the firing unit of the heat generator. N S - - 1

Burner Oper Time Overall runtime of the burner in hours, which is stored in the firing unit of the heat generator. N S - - 1 h

Tab. 6-6 Parameters in the "Configuration" rotary switch setting, "Lambda-Gx" level

Parameter Description Access Setting range

Min / Max

Factory

setting

Incre-

ment

BE HF

1x Hot Water Start of a one-time hot water generation to the set target value [T-DHW Setpoint 1] without time

limit, independent of the heating programs.

E E Off

On

Off -

DHW Reloadtime Setting limits the period of time for hot water generation to the set target value [T-DHW Setpoint

1]. After the period of time has elapsed, the control unit switches back to the previously active

operating mode. Hot water generation is carried out to the then current target value.

E E 0 - 240 min 0 min 1 min

Tab. 6-7 Parameters in the "DHW Reheating" rotary switch setting

Loading...

Loading...