7 | Piping installation

Installer reference guide

35

RXTJ-A_RXTA-C_RXTM-A_RXTP-A

R32 split series

4P728168-1 – 2023.03

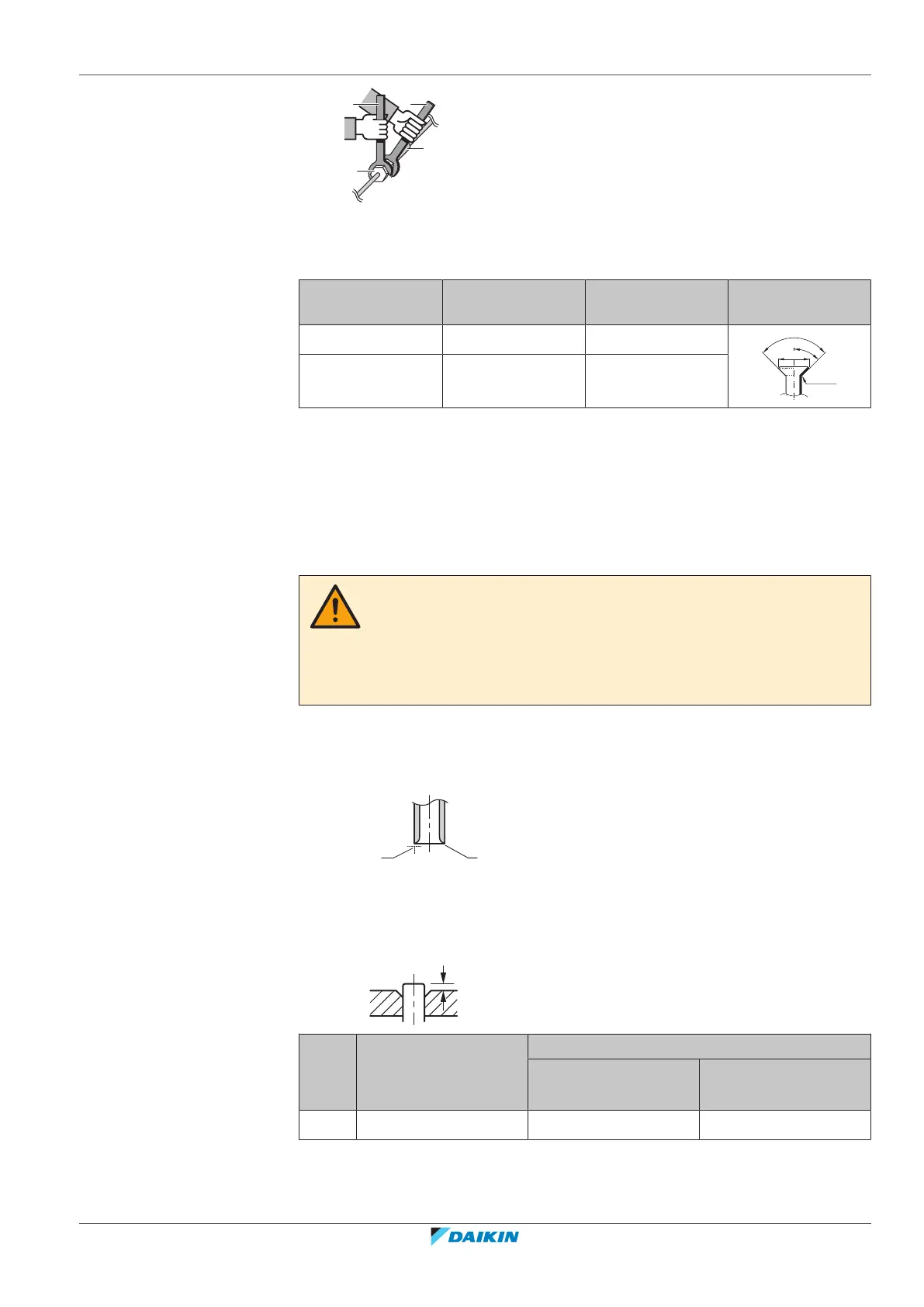

a Torque wrench

b Spanner

c Piping union

d Flare nut

Piping size (mm) Tightening torque

(N•m)

Flare dimensions

(A) (mm)

Flare shape (mm)

Ø6.4 15~17 8.7~9.1

Ø9.5 33~39 12.8~13.2

7.2.4 Pipe bending guidelines

Use a pipe bender for bending. All pipe bends should be as gentle as possible

(bending radius should be 30~40 mm or larger).

7.2.5 To flare the pipe end

CAUTION

▪ Incomplete flaring may cause refrigerant gas leakage.

▪ Do NOT re-use flares. Use new flares to prevent refrigerant gas leakage.

▪ Use flare nuts that are included with the unit. Using different flare nuts may

cause refrigerant gas leakage.

1 Cut the pipe end with a pipe cutter.

2 Remove burrs with the cut surface facing down so that the chips do NOT enter

the pipe.

a Cut exactly at right angles.

b Remove burrs.

3 Remove the flare nut from the stop valve and put the flare nut on the pipe.

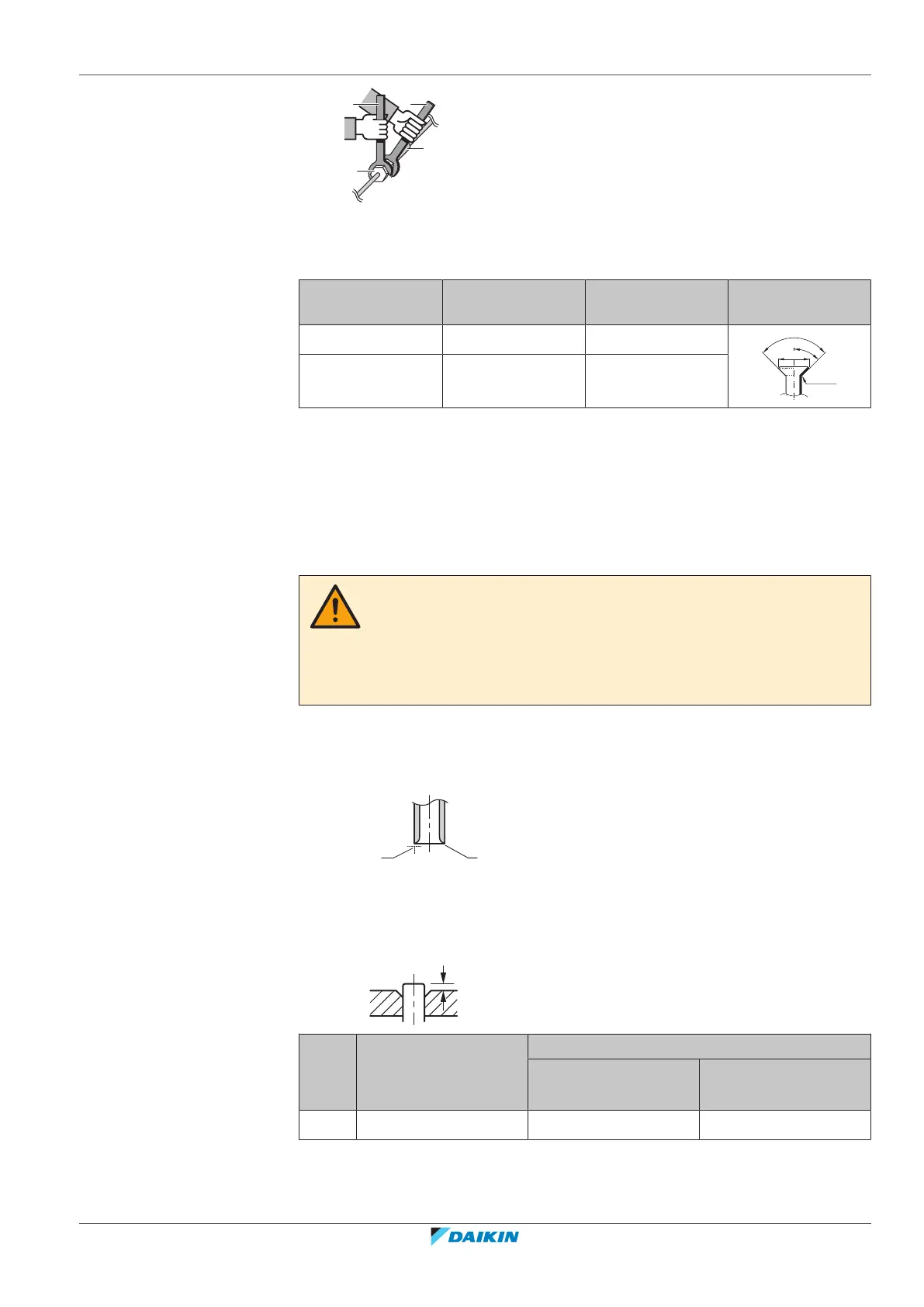

4 Flare the pipe. Set exactly at the position as shown in the following figure.

Flare tool for R32

(clutch type)

Conventional flare tool

Clutch type

(Ridgid-type)

Wing nut type

(Imperial-type)

A 0~0.5mm 1.0~1.5mm 1.5~2.0mm

5 Check that the flaring is properly made.

Loading...

Loading...