7 | Piping installation

Installer reference guide

39

RXTJ-A_RXTA-C_RXTM-A_RXTP-A

R32 split series

4P728168-1 – 2023.03

NOTICE

▪ Connect the vacuum pump to the service port of the gas stop valve.

▪ Make sure that the gas stop valve and liquid stop valve are firmly closed before

performing the leak test or vacuum drying.

7.3.3 To check for leaks

NOTICE

Do NOT exceed the unit's maximum working pressure (see "PS High" on the unit

name plate).

NOTICE

ALWAYS use a recommended bubble test solution from your wholesaler.

NEVER use soap water:

▪ Soap water may cause cracking of components, such as flare nuts or stop valve

caps.

▪ Soap water may contain salt, which absorbs moisture that will freeze when the

piping gets cold.

▪ Soap water contains ammonia which may lead to corrosion of flared joints

(between the brass flare nut and the copper flare).

1 Charge the system with nitrogen gas up to a gauge pressure of at least

200kPa (2bar). It is recommended to pressurize to 3000kPa (30bar) in order

to detect small leaks.

2 Check for leaks by applying the bubble test solution to all connections.

3 Discharge all nitrogen gas.

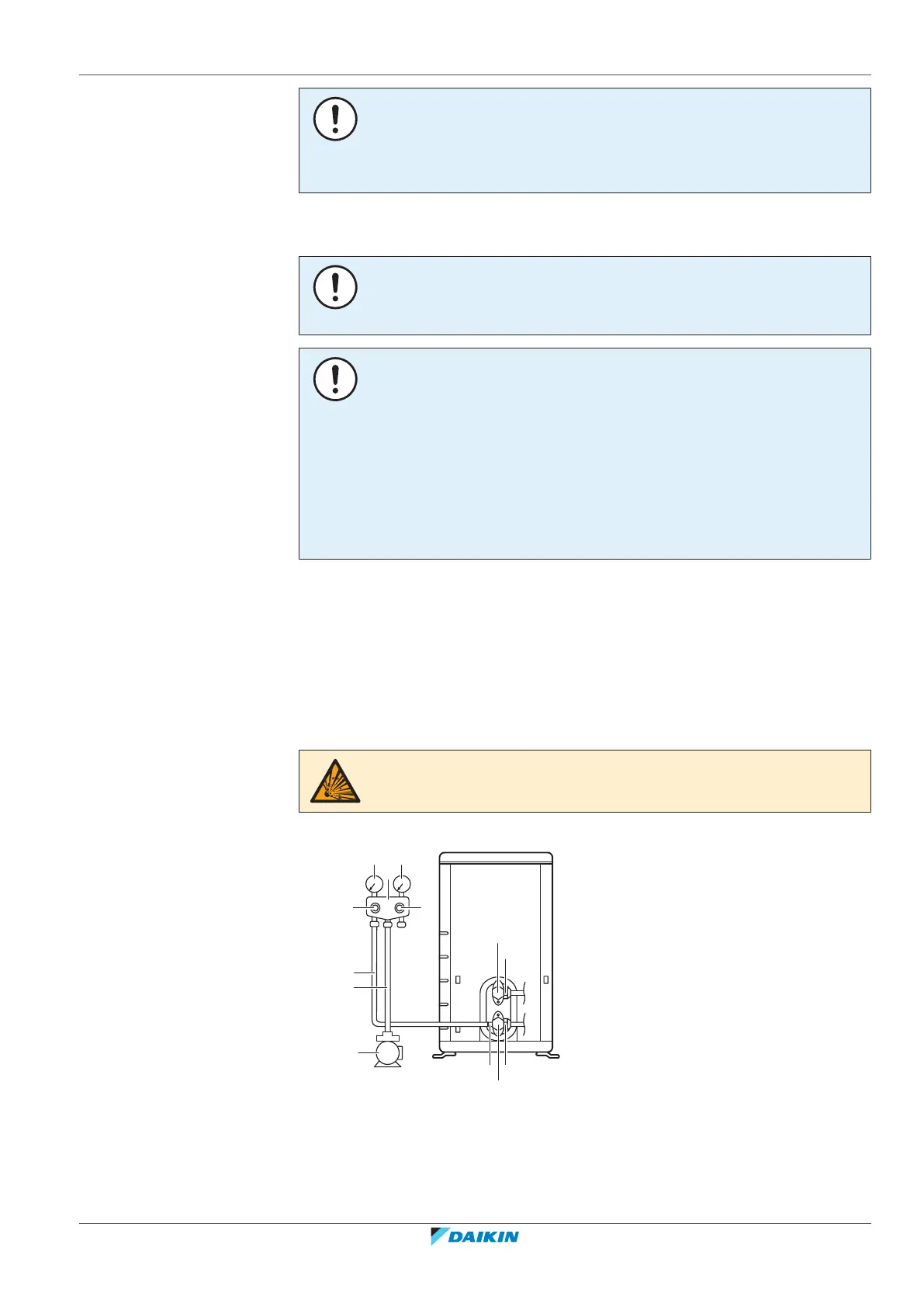

7.3.4 To perform vacuum drying

DANGER: RISK OF EXPLOSION

Do NOT open the stop valves before the vacuum drying is finished.

Connect the vacuum pump and manifold as follows:

a Low pressure gauge

b Gauge manifold

c High pressure gauge

d Low-pressure valve (Lo)

e High-pressure valve (Hi)

f Charging hoses

Loading...

Loading...