8 | Charging refrigerant

Installer reference guide

44

RXTJ-A_RXTA-C_RXTM-A_RXTP-A

R32 split series

4P728168-1 – 2023.03

If pump down is needed in case of dismantling or relocating the system, see

"15.2To pump down"[460] for more details.

8.7 To check refrigerant piping joints for leaks after charging refrigerant

1 Perform the leak tests see "7.3Checking the refrigerant piping"[438].

2 Charge refrigerant.

3 Check for refrigerant leaks after charging (see below)

Tightness test of field-made refrigerant joints indoors

1 Use a leakage test method with a minimum sensitivity of 5 g of refrigerant/

year. Test leaks using a pressure of at least 0.25 times the maximum working

pressure (see "PS High" on the unit nameplate).

If a leak is detected

1 Recover the refrigerant, repair the joint, and repeat the test.

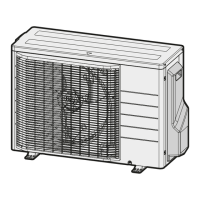

8.8 To fix the fluorinated greenhouse gases label

1 Fill in the label as follows:

Contains fluorinated greenhouse gases

2

1

1

1

2

2

kg

tCO

2

eq

GWP × kg

1000

=

=

+

kg

=

kg

=

GWP: XXX

RXXX

a If a multilingual fluorinated greenhouse gases label is delivered with the unit (see

accessories), peel off the applicable language and stick it on top of a.

b Factory refrigerant charge: see unit name plate

c Additional refrigerant amount charged

d Total refrigerant charge

e Quantity of fluorinated greenhouse gases of the total refrigerant charge

expressed as tonnes CO

2

equivalent.

f GWP = Global Warming Potential

NOTICE

Applicable legislation on fluorinated greenhouse gases requires that the refrigerant

charge of the unit is indicated both in weight and CO

2

equivalent.

Formula to calculate the quantity in CO

2

equivalent tonnes: GWP value of the

refrigerant × total refrigerant charge [in kg] / 1000

Use the GWP value mentioned on the refrigerant charge label.

2 Fix the label on the inside of the outdoor unit near the gas and liquid stop

valves.

Loading...

Loading...