www.DaikinApplied.com 43 IOM 1207-6 • TRAILBLAZER

®

MODEL AGZ CHILLERS

Pump Operating Control

Constant Flow

The pumps will run at constant speed and will start and stop

automatically with the chiller unit. When the chiller is enabled to

run by having its MicroTech

®

III unit controller in the Auto state

or by a signal from a BAS (not necessarily with compressors

running based on availability of a cooling load), the pump

panel will receive a signal to start from the chiller controller

when either the chilled water leaving or entering temperature

reaches the chiller freeze point setting to help prevent freeze

up. When there is sucient ow to close the ow switch within

a timed period (recirc timer), a proof-of-ow signal is sent to

the chiller and the pump is in the Run state. If there is a call for

cooling based on the chilled water temperature, the chiller will

commence its compressor startup procedure. If there is no call

for cooling, the chiller will be on stand-by waiting for load.

If the ow switch does not see ow, the pump remains in the

Start state until ow is established, at which time the pump will

be in the Run state. Flow is recognized when the ow switch

indicates ow for longer than the recirc timer setpoint.

The Run state is a control condition established by satisfying

certain conditions. The Start state means that a digital signal

has been sent to the pump for it to start running.

When starting the chiller, it is prudent to be sure there is ow

so the chiller compressors will be able to start based on a call

for cooling due to high chilled water temperature. Observing

water pressure gauges can conrm ow.

Flow interruption will open the ow switch, sending a signal to

the chiller to shut down and also de-energize the pump. If the

chiller is turned o, the pump will shut o after a timed period

to allow water circulation during refrigerant pumpdown.

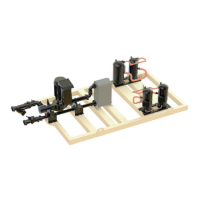

Variable Flow with Pump VFD

The operating cost savings resulting from using variable

chilled water ow via a pump VFD is well known. In the past,

however, its usage has been somewhat limited by the cost

and uncertainty of eld installing the required system pressure

dierential sensors. Daikin Applied oers a variable chilled

water ow system, completely self-contained within the pump

package, by simply ordering the optional pump VFD and no

external sensors are required when operating in Sensorless

Pressure Control.

There are four pump operating modes available with the

optional factory-installed variable ow VFD is selected on the

pump package is equipped with the variable frequency drive

(VFD) option:

1. Sensorless Pressure Control (default setting)

2. BAS Control

3. Remote Sensor Control

4. Locally Selected Constant Speed Control

Sensorless Pressure Control

Onboard measurements allow control of the pump speed

to optimize chilled water ow with respect to water system

pressure. External pressure sensors are not required,

eliminating design and installation eort. The unit is factory-

congured for this mode.

NOTE: Sensorless operation is only allowed for single chiller

systems. Systems with parallel chiller operation must use one

of the other control methods.

The default control mode for Sensorless pumps is ‘Quadratic

Pressure Control’ where the controller is set to control the

speed according to a ‘control curve’ between max and min

ow (see ). The control curve is designed to replicate sensor

positions at varying distances from the pump based on power,

frequency, pressure, and ow across the ow range of the

pump. Speed and pressure are adjusted to match the system

load without the need for a sensor located at the most remote

load point.

The quadratic measurements enable the pump to continuously

identify the head and ow at any point in time which gives

accurate pressure control without the need for external

feedback signals such as a remote sensor. Incorporating the

pump’s hydraulic data into the controller and removing sensors

results in true integration of all components and removes the

risk of remote sensor failure.

Figure 46: Pump Control Curve

Previously, a dierential pressure sensor was placed at the

most remote load, across the supply piping and return piping

encompassing the valve and coil set, as common practice for

system energy eciency. Sensorless control can replicate this

control without the need for that remote sensor. As the ow

required by the system is reduced, the pump automatically

reduces the head developed according to the pre-set control

curve.

In systems with a remote sensor, it is often found that using

a dierential pressure sensor to sense the pressure across

a remote load could theoretically result in loads close to the

pump being under-pumped. The situation would be where the

load at a loop extremity is satised and the control valve closes

while a load close to the pump needs full ow. The probability

of this occurring is remote but it is possible. One answer to this

is to move the sensor closer to the pump (two-thirds of the way

Loading...

Loading...