www.DaikinApplied.com 115 IOM 1207-6 • TRAILBLAZER

®

MODEL AGZ CHILLERS

Pump Start Control (MicroTech

®

III)

The standard arrangement is for the MicroTech

®

III unit

controller pump output signal to automatically start and stop

the pump(s). The methods and settings are discussed in See

Evaporator Pump Control on page 88.

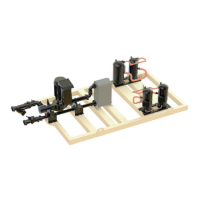

Details on pump package installation and application

considerations begin on page 41.

Pump VFD Operation

The VFD constantly monitors the chilled water system’s state.

When the building cooling load drops, air side controls will

start to close in order to control the space temperature. At that

instant in time, the pump power draw will start to drop. The

drive will notice this and slow down the pump (Hz output will

decrease) which then triggers a decrease in ow and head

since the pump impeller rpm is dropping.

The reverse is true when the load increases (valves open). The

power draw will increase and the drive will speed up (Hz goes

up) and the ow and head increases.

Both ow and head will uctuate and since they are being read

instantaneously, as opposed to an averaged value, even the

slightest change is registered on the screen.

A building’s cooling load tends to change slowly and it may be

dicult to discern load changes by merely observing the VFD

display. However, the pump rpm, Hz and kW can be noted over

time and used for reference. A given building load will have a

discrete reading.

Operating the VFD Controller

The VFD incorporates an integrated graphic local display and

keypad to select mode, change parameters and view status

and alarms.

The unit is shipped in the sensorless mode. If this mode is to

be used, no programming is required.

Control Functions

1. Graphical display with Status lines.

2. Menu keys and indicator lights (LED’s) - selecting mode,

changing parameters, and switching between display

functions.

3. Navigation keys and indicator lights (LEDs).

4. Operation keys and indicator lights (LEDs).

Figure 86: Graphical Local Control Panel (GLCP)

The LCD-display is back-lit with a total of 6 alpha-numeric

lines. All data is displayed on the LCP which can show up to

ve operating variables while in [Status] mode.

Status line (a): The status line is programmable with the

normal setup displaying hertz on the left, Pump kw in the

middle, and rpm on the right. Showing the status when in

status mode or up to two variables when not in status mode

and in the case of Alarm/ Warning. The number of the Active

Set-up (Sensorless mode being setup 1) is shown.

Data Lines (b): Operator data lines displaying data and

variables dened or chosen by the user. By pressing the

[Status] key, up to one extra line can be added. It shows up

to 5 variables with related unit regardless of status. In case of

alarm/warning, the warning is shown instead of the variables.

Normal setup is to show feet of head and gpm.

Status line (c): Status shows the state of the inverter such as

Run OK, Running on Auto Remote Running

Operating variables on the data lines (b) will vary depending on

the operating mode.

• Sensorless: displays gpm and head

• External Sensor: displays gpm and head

• BAS: congured by the BAS

• Hand: displays Hz

Status Display I

This read-out state is standard after start-up or initialization.

Status Display II

Use [INFO] to obtain information about the value/measurement

linked to the displayed operating variables (1.1, 1.2, 1.3, 2, and

3) shown in the display in Figure 87.

(a) Status Line

(b) Data Lines

(c) Status Line

Loading...

Loading...