IM 915-13 • VISION - EXTENDED SIZES 42 www.DaikinApplied.com

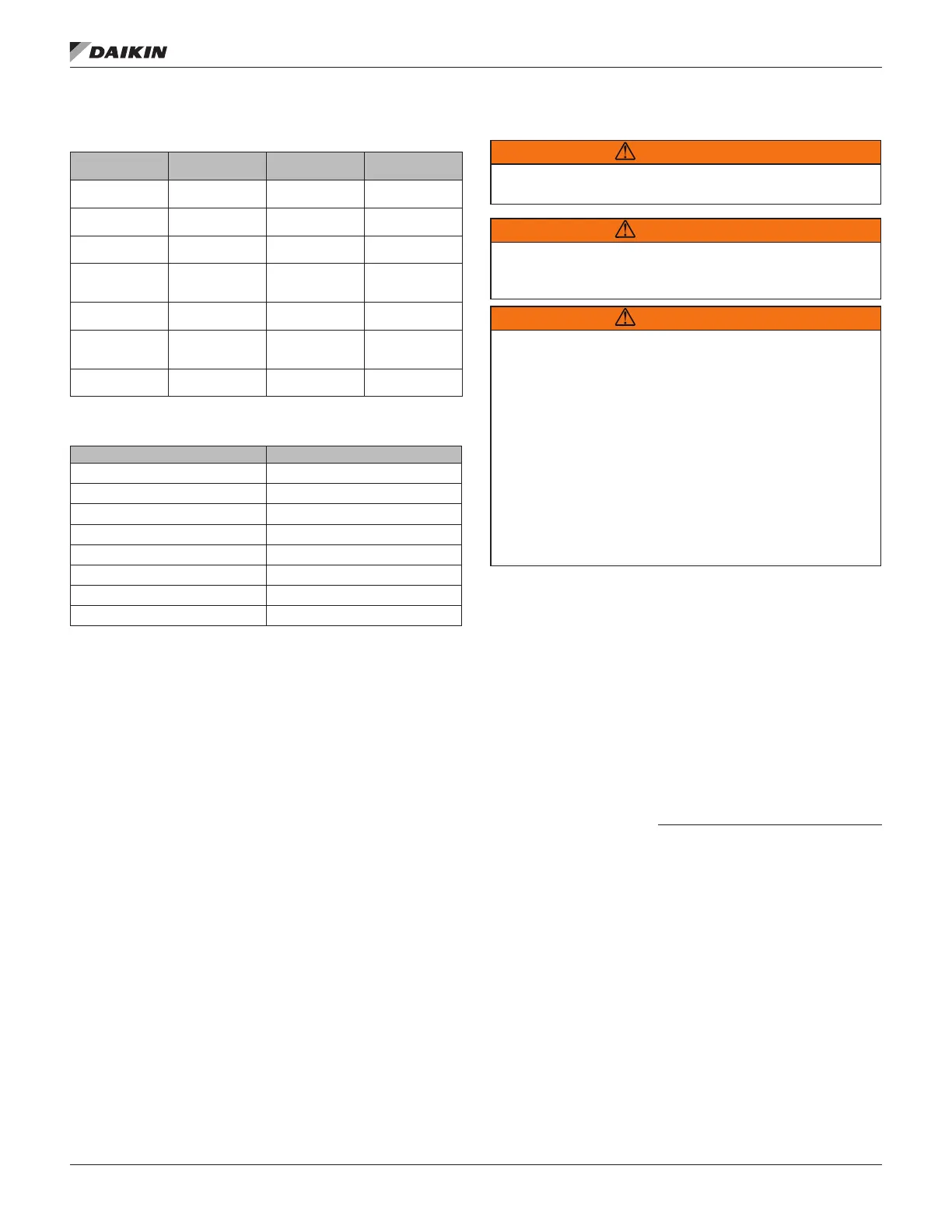

Table 24: Re-lubrication Intervals

Speed

Bearing

Temperature

Relub. intervals

100 rpm

Up to 120°F

(50°C)

Clean 6 to 12 months

500 rpm

Up to 150°F

(65°C)

Clean 2 to 6 months

1000 rpm

Up to 210°F

(100°C)

Clean

2 weeks to 2

months

1500 rpm

Over 210°F

(100°C) to 250°F

(120°C)

Clean Weekly

Above 1500 rpm

Up to 150°F

(65°C)

Dirty/wet 1 week to 1 month

Max catalog rating

Over 150°F

(65°C) to 250°F

(120°C)

Dirty/wet Daily to 2 weeks

Above 250°F

(120°C)

Contact Browning

Table 25: Recommended Fan Re-lubrication Grease Charge

Shaft Size – in. (mm) Oz. (g)

1/2 to 3/4 (20) 0.03 (0.85)

7/8 to 1-3/16 (25-30) 0.10 (2.84)

1-1/4 to 1-1/2 (35-40) 0.15 (4.25)

1-11/16 to 1-15/16 (45-50) 0.20 (5.67)

2 to 2-7/16 (55-60) 0.30 (8.51)

2-1/2 to 2-15/16 (65-70) 0.50 (15.59)

3 to 3-7/16 (75-80) 0.85 (24.10)

3-1/2 to 4 (85-105) 1.50 (42.53)

Fan Drive Adjustments

Before servicing fan lock out and tag out all power to the unit.

Fans or belts can cause severe personal injury or death.

Do not open the hinged access door and screw-fastened

access panels while the unit is operating. Moving parts and

strong suction forces can severe personal injury or death.

Moving belt and fan can cause severe personal injury or death.

During installation and lter maintenance:

• Verify that the belt and fan guards on plenum fan units are

always in place.

• Lock and tag out fans to prevent accidental start up.

• Do not enter the lter compartment until the fan is completely

stopped.

• Use approved equipment for reaching lters located

above normal reach. Do not step on lter frames or unit

components.

• Floor surfaces must be dry and free of oil or grease.

Upon completion of the air balance, replace the variable

pitched motor sheave with a properly sized, xed sheave. A

matching xed sheave provides longer belt and bearing life

and minimizes vibration. Initially, it is best to have a variable

pitched motor sheave for the purpose of air balancing. Once

the balance is achieved, xed sheaves maintain balancing and

alignment more eectively. Replace the adjustable sheaves

with xed sheaves.

With the electrical power disconnected, locked and tagged

out, measure the diameter of the V-belt outer surface where

it passes around the sheave (pitch diameter). Calculate fan

speed from the motor nameplate rpm.

Measured diameter at motor sheave

Fan rpm = motor rpm ×

Measured diameter at fan sheave

Loading...

Loading...