14 Piping installation

Installation and operation manual

24

RXYSQ4~6T8V/YB(*)

VRV IV-S system air conditioner

4P482275-1B – 2020.10

14.3.6 To insulate the refrigerant piping

After finishing the leak test and vacuum drying, the piping must be

insulated. Take into account the following points:

▪ Make sure to insulate the connection piping and refrigerant branch

kits entirely.

▪ Be sure to insulate the liquid and gas piping (for all units).

▪ Use heat resistant polyethylene foam which can withstand a

temperature of 70°C for liquid piping and polyethylene foam which

can withstand a temperature of 120°C for gas piping.

▪ Reinforce the insulation on the refrigerant piping according to the

installation environment.

▪ If there is a possibility that condensation on the stop valve might

drip down into the indoor unit through gaps in the insulation and

piping because the outdoor unit is located higher than the indoor

unit, this must be prevented by sealing up the connections. See

below figure.

a Insulation material

b Caulking etc.

14.4 Charging refrigerant

14.4.1 Precautions when charging refrigerant

WARNING

▪ ONLY use R410A as refrigerant. Other substances

may cause explosions and accidents.

▪ R410A contains fluorinated greenhouse gases. Its

global warming potential (GWP) value is 2087.5. Do

NOT vent these gases into the atmosphere.

▪ When charging refrigerant, ALWAYS use protective

gloves and safety glasses.

NOTICE

If the power of some units is turned off, the charging

procedure cannot be finished properly.

NOTICE

Be sure to turn ON the power 6 hours before operation in

order to have power running to the crankcase heater and

to protect the compressor.

NOTICE

If operation is performed within 12 minutes after the indoor

and outdoor units are powered on, the compressor will not

operate before the communication is established in a

correct way between outdoor unit(s) and indoor units.

NOTICE

Before starting charging procedures, check if the 7‑LEDs

display is as normal (see "To access mode 1 or 2"[429]),

and there is no malfunction code on the user interface of

the indoor unit. If a malfunction code is present, see

"19.1Solving problems based on error codes"[434].

NOTICE

Make sure all connected indoor units are recognised

(setting [1‑5]).

NOTICE

Close the front panel before any refrigerant charge

operation is executed. Without the front panel attached the

unit cannot judge correctly whether it is operating properly

or not.

NOTICE

In case of maintenance and the system (outdoor unit+field

piping+indoor units) does not contain any refrigerant any

more (e.g., after refrigerant reclaim operation), the unit has

to be charged with its original amount of refrigerant (refer

to the nameplate on the unit) and the determined additional

refrigerant amount.

14.4.2 To determine the additional refrigerant

amount

INFORMATION

For final charge adjustment in a test laboratory, contact

your dealer.

INFORMATION

Note down the amount of additional refrigerant that is

calculated here, for later use on the additional refrigerant

charge label. See "To fix the fluorinated greenhouse gases

label"[425].

Formula:

R=[(X

1

×Ø9.5)×0.059+(X

2

×Ø6.4)×0.022]

R Additional refrigerant to be charged [in kg and rounded off

to 1 decimal place]

X

1...2

Total length [m] of liquid piping size at Øa

Metric piping. When using metric piping, replace the weight factors

in the formula by the ones from the following table:

Inch piping Metric piping

Piping Weight factor Piping Weight factor

Ø6.4mm 0.022 Ø6mm 0.018

Ø9.5mm 0.059 Ø10mm 0.065

14.4.3 To charge refrigerant

To speed up the refrigerant charging process, it is in case of larger

systems recommended to first pre-charge a portion of refrigerant

through the liquid line before proceeding with the manual charging. It

can be skipped, but charging will take longer then.

Pre-charging refrigerant

Pre-charging can be done without compressor operation, by

connecting the refrigerant bottle to the service port of the liquid stop

valve.

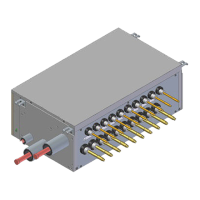

1 Connect as shown. Make sure that all outdoor unit stop valves,

as well as valve A are closed.

a Pressure reducing valve

b Nitrogen

c Weighing scales

Loading...

Loading...