IOM 1322 • WATER-COOLED SCROLL COMPRESSOR 12 www.DaikinApplied.com

Condenser Water Piping

Arrange the condenser water so the water enters the bottom

connection of the condenser. The condenser water will

discharge from the top connection. Failing to arrange the

condenser water as stated above will negatively aect the

capacity and eciency.

Water ow through the condenser should only be during

compressor operation. Pumps may be enabled by the chiller or

BAS.

Field installed water piping to the condenser must include:

• Install a cleanable strainer with perforations no larger

than 0.125” (3.2 mm) diameter in the inlet piping .

• Install pressure gauges in the inlet and outlet water lines

to the condenser. Pressure drop through the condenser

should be measured to determine ow on the pressure

drop/ow curves beginning on page 19.

It is recommended that the eld installed water piping to the

chiller include:

• Vibration eliminators are recommended in both the supply

and return water lines to reduce vibration and noise

transmissions to the building.

• A preliminary leak check of the water piping should be

made before lling the system.

• Shuto valves to isolate the unit from the piping system

during unit servicing.

• Regular water analysis and chemical water treatment

on the condenser is recommended immediately upon

equipment start-up.

Condensers are drained of water in the factory and are shipped

with the condenser drain plugs in the heads removed and

stored in a bag in the control panel. Be sure to replace plugs

prior to lling the vessel with uid.

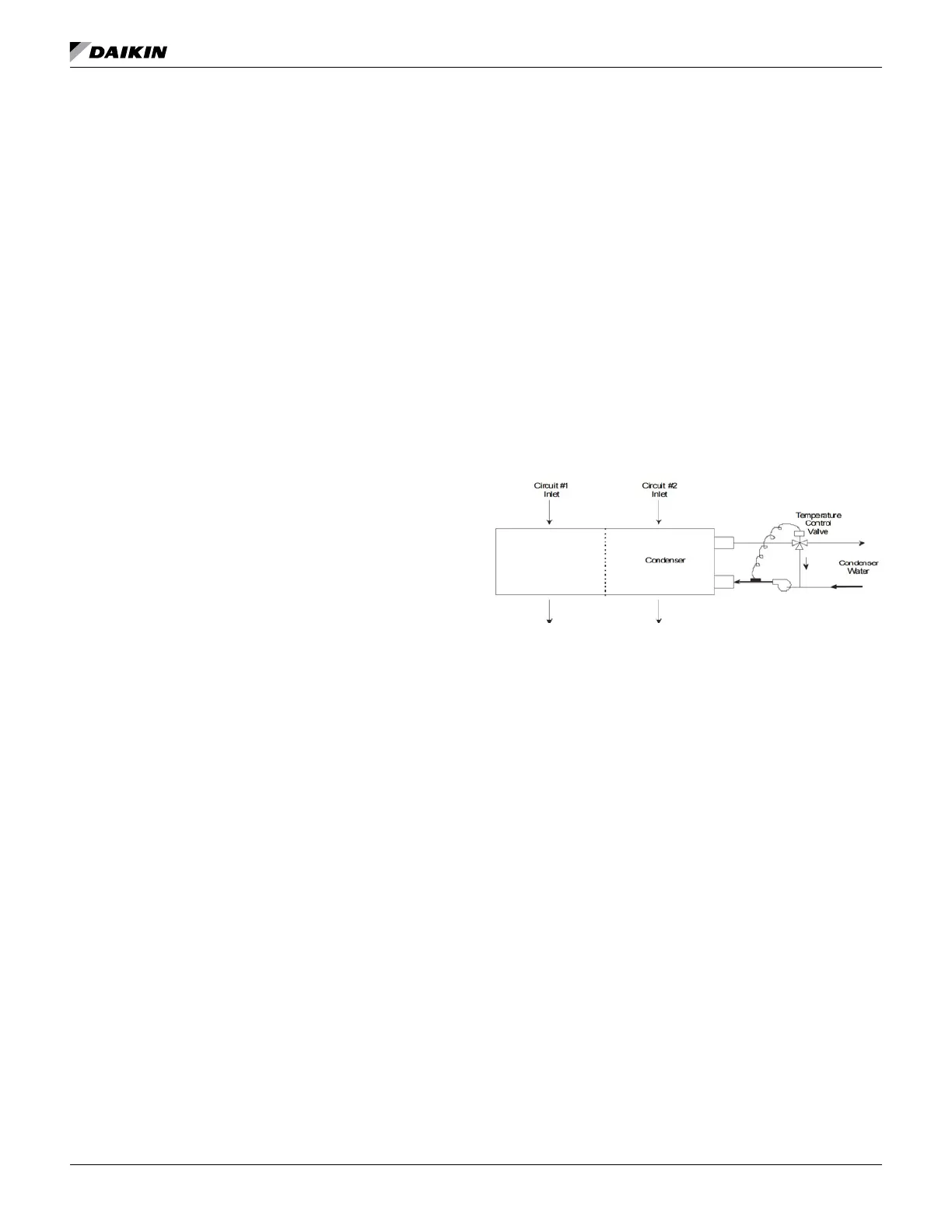

Water-cooled condensers can be piped for use with cooling

towers, well water, or heat recovery applications. Cooling

tower applications must be made with consideration of freeze

protection and scaling problems. Contact the cooling tower

manufacturer for equipment characteristics and limitations

for the specic application. Head pressure control must

be provided if the entering condenser water can fall below

60°F. The WGZ condenser has two refrigerant circuits with a

common condenser water circuit. This arrangement makes

head pressure control with discharge pressure actuated control

valves dicult.

If the tower water temperature cannot be maintained at a

60°F minimum, or when pond, lake, or well water that can fall

below 60°F (15°C) is used as the condensing medium, special

discharge pressure control must be used. A water recirculating

system with recirculating pump as shown in Figure 5:

Recirculating Discharge Water System is recommended. This

system also has the advantage of maintaining tube velocity to

help prevent tube fouling. The pump must cycle with the chiller.

Figure 5: Recirculating Discharge Water System

Loading...

Loading...