Instruction APP pump instruction APP (W) 5.1-10.2

7

180R9072 / 521B0747 / DKCFN.PI.010.D5.02 / 11.2014

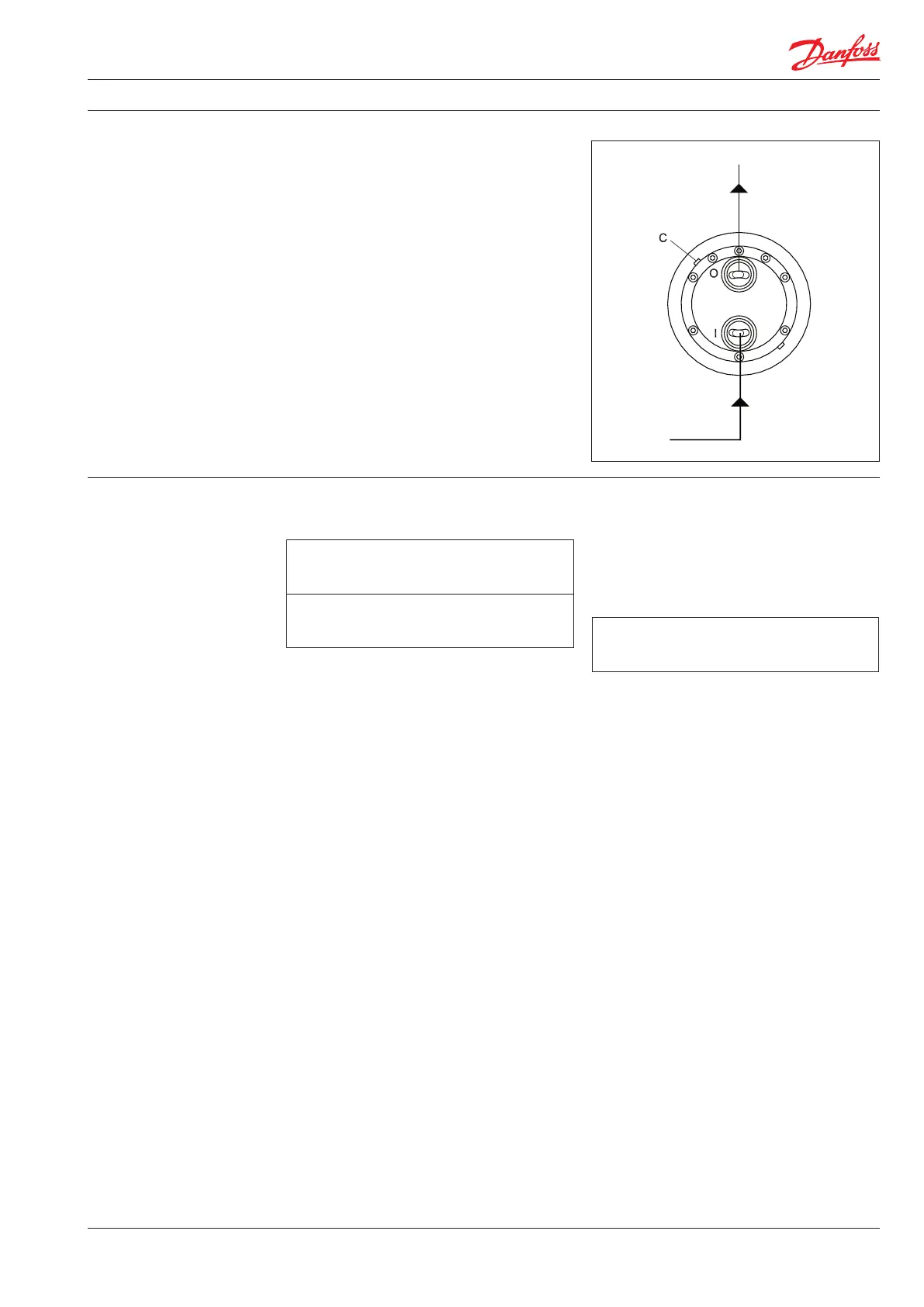

Before start-up, loosen the top bleeding plug “C”.

When water appears from the bleeding plug,

retighten the plug. With its inlet line connected

to the water supply or the tank, the pump is now

started with open outlet port.

At the initial start of the system, the pump

should be run without pressure for about

5 minutes, thus removing possible impurities

from pipes, hoses, etc. However, the system

should be ushed before start-up – without the

connected pump.

WARNING

Make sure that the direction of rotation of the

electric motor corresponds to the direction of

rotation of the pump. Otherwise the pump will

be damaged if a check valve is placed between

pump and tank.

4. Initial start-up

521B0747 DKCFN.PI.010.D3.ML

Before start-up, loosen the top bleeding plug “C”. When water appears

from the bleeding plug, retighten the plug. With its inlet line connected

to the water supply or the tank, the pump is now started with open

At the initial start of the system, the pump should be run without

pressure for about 5 minutes, thus removing possible impurities from

However, the system should be fl ushed before start-up

However, the system should be fl ushed before start-up

– without the connected pump

– without the connected pump

Make sure that the direction of rotation of the electric motor

corresponds to the direction of rotation of the pump. Otherwise the

pump will be damaged if a check valve is placed between pump and

The pumps are preserved with antifreeze Dowcal N.

Vor der Inbetriebnahme, lösen Sie die obere Entlüftungsschraube “C”.

Wenn Wasser aus der Entlüftungsschraube austritt, diese erneut

anziehen. Die Pumpe – die Einlaßleitung zur Wasserversorgung oder

zum Tank angeschlossen – wird jetzt mit off enem Auslaßanschluß

Bei der ersten Inbetriebnahme sollte die Pumpe für etwa 5 Minuten

drucklos laufen, um Schmutzpartikel aus Rohren, Schläuchen usw.

Jedoch sollte das System vor der ersten Inbetriebnahme

Jedoch sollte das System vor der ersten Inbetriebnahme

– ohne die angeschlossene Pumpe - durchgespült werden.

– ohne die angeschlossene Pumpe - durchgespült werden.

Beachten Sie, daß die Drehrichtung vom Elektromotor mit der Dreh-

richtung der Pumpe übereinstimmt, da anderenfalls die Pumpe zerstört

Die Pumpen werden mit Frostschutzmittel Dowcal N

4. Mise en route initiale

Avant la mise en route, desserrer le bouchon de purge supérieur “C”.

Lorsque l’eau apparaît, resserrer le bouchon.

Avec la conduite d’aspiration raccordée à l’arrivée d’eau ou au réservoir

rempli d’eau, la pompe sera démarrée avec la conduite de refoulement

(haute pression) ouverte.

Lors du démarrage initial, la pompe fonctionnera environ 5 minutes sans

pression afi n d’évacuer de possible impuretés des tubes, fl exibles, etc.

Le système sera toujours rincé avant la mise en route sans que la pompe

Le système sera toujours rincé avant la mise en route sans que la pompe

Vérifi ez que le sens de rotation du moteur électrique corresponde à celui

de la pompe. Dans le cas contraire, la pompe sera endommagée si un

clapet anti-retour est installé entre la pompe et le réservoir.

Les pompes sont protégées par de l’antigel Dowcal N.

Antes de arrancar, afl oje el tapón de sangrado C. Cuando aparezca agua,

enrosque el tapón. Con esta línea de entrada conectada al suministro

de agua o al tanque de agua, ahora se puede poner en funcionamiento

la bomba de agua con un puerto de salida abierto.

La primera vez que ponga en funcionamiento el sistema, la bomba debe

funcionar sin presión durante unos 5 minutos para así eliminar las impu-

rezas que pueda haber en las tuberías, mangueras, etc.

sistema deberá de ser enjuagado (fl ushed) antes del arranque inicial sin

sistema deberá de ser enjuagado (fl ushed) antes del arranque inicial sin

Asegúrese de que la dirección de la rotación del motor eléctrico corres-

ponda a la dirección de la rotación de la bomba. Si no, la bomba puede

dañarse si se coloca una válvula antiretorno entre la bomba y el tanque.

Las bombas se almacenan con el anticongelante Doweal N.

5. Operation 5.1 Temperature

Fluid temperature:

Min. +2° C to max. +50° C

(Min. +35.6° F to max. +122° F)

Ambient temperature:

Min. +2° C to max. +50° C

(Min. +35.6° F to max. +122° F)

In case of lower operating temperatures, please

contact the Danfoss High Pressure Pumps.

5.2 Pressure

The inlet pressure must be min. 0.5 barg

(7.25 psig) and max. 5 barg(72.5 psig). At lower

pressures the pump will cavitate, resulting in

damage of the pump.

Max. pressure on the pump’s outlet line should

be limited at 80 barg (1160 psig) continuously.

Short-term pressure peaks (e.g. in connection

with closing of a valve) of up to 100 barg

(1450 psig) are acceptable.

Note: The pump unit should include a pressure

gauge on the high-pressure side.

5.3 Dry running

When running, the pump must always be

connected to the water supply in order to avoid

damage if it should run dry.

In systems with water tank it is recommended to

build in a level gauge in the tank to avoid the risk

of running dry.

5.4 Disconnection

If the inlet line is disconnected from the water

supply, the pump will be emptied of water

through the disconnected inlet line.

When starting up again, follow the bleeding

procedure described under section 4: Initial start

up.

5.5 Storage

When preparing the pump for long-term storage

or for temperatures below the freezing point,

ush the pump with an anti-freeze medium type

monopropylene glycol to prevent internal

corrosion or frost in the pump.

For further information on anti-freeze media,

please contact the Danfoss High Pressure Pumps.

Recommended procedure:

5.5.1 Open-ended systems with water supply

from tank

1. Empty the tank of water and empty the

pump housing through the lower bleeding

plug. When the pump is empty, retighten

the plug.

2. Through the upper bleeding plug, ll the

pump housing with anti-freeze medium.

Pour anti-freeze medium into the tank.

Connect a hose to the outlet of the pump

and lead the other end of the hose back to

tank.

3. Quickly start and stop the pump. Make

sure that the pump does not run dry. The

pump is now protected against internal

corrosion and frost.

Storage temperature:

Min. -40° C to max. +70° C

(Min. -40° F to max. +158° F)

Loading...

Loading...