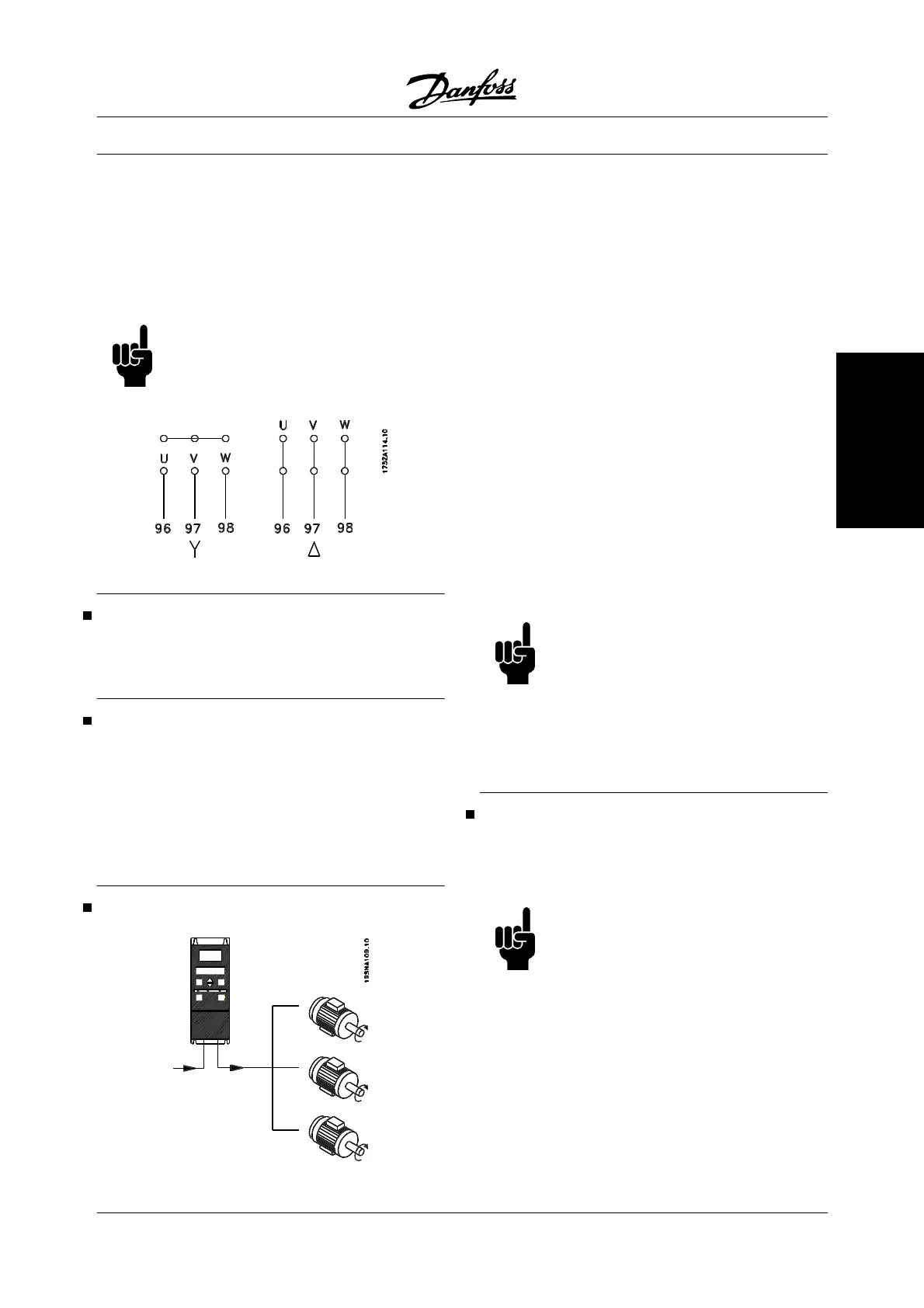

All types of three-phase asynchronous standard mo-

tors can be connected to an adjustable frequency

drive. Normally, small motors are star-connected

(230/400 V, / Y), while large motors are delta-con-

nected (400/690 V, / Y). The correct connection

mode and voltage can be read from the motor name-

plate.

NOTE

In motors without phase insulation paper,

an LC filter should be fitted on the output

of the adjustable frequency drive.

Direction of motor rotation

To change the direction of motor rotation, switch any

two phases at the drive output or at motor terminals.

Motor thermal protection

The electronic thermal relay in UL approved variable

frequency drives has received the UL approval for sin-

gle motor protection, when parameter 128 Motor ther-

mal protection has been set for ETR Trip and

parameter 105 Motor current, I

M, N

has been program-

med to the rated motor current (see motor nameplate).

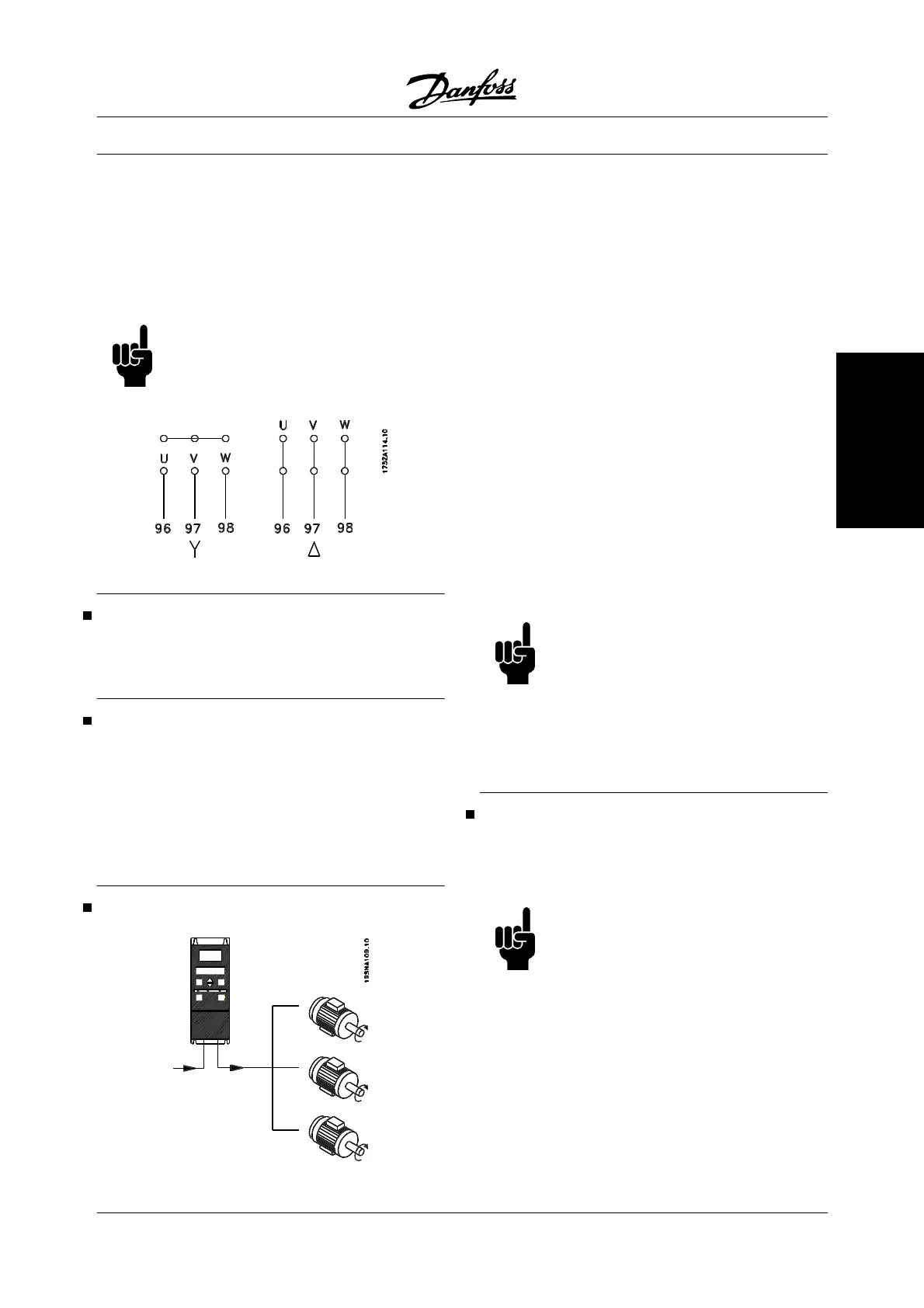

Parallel connection of motors

The adjustable frequency drive is able to control sev-

eral motors connected in parallel. If the motors are to

have different rpm values, use motors with different

rated rpm values. Motor rpm is changed simultane-

ously, which means that the ratio between the rated

rpm values is maintained across the range. The total

current consumption of the motors is not to exceed the

maximum rated output current I

INV

for the adjustable

frequency drive.

Problems may arise at the start and at low rpm values

if the motor sizes are widely different. This is because

the small motors' relatively high ohmic resistance in

the stator calls for a higher voltage at the start and at

low rpm values.

In systems with motors connected in parallel, the elec-

tronic thermal relay (ETR) of the adjustable frequency

drive cannot be used as motor protection for the indi-

vidual motor. For this reason, further motor protection

must be used, such as thermistors in each motor or an

individual thermal relay, for example (circuit breakers

are not a suitable means of protection).

NOTE

Parameter 107 Automatic motor adapta-

tion, AMT cannot be used when motors

are connected in parallel. Parameter 101

Torque characteristic must be set to Spe-

cial motor characteristics [8] when motors

are connected in parallel.

Motor cables

See Technical data for correct dimensioning of motor

cable cross-section and length. Always comply with

national and local regulations on cable cross-section.

NOTE

If an unshielded/unarmored cable is used,

some EMC requirements are not com-

plied with, see EMC test results in the De-

sign Guide.

If the EMC specifications regarding emissions are to

be complied with, the motor cable must be shielded/

armored unless otherwise stated for the RFI filter in

question. It is important to keep the motor cable as

short as possible so as to reduce the noise level and

leakage currents to a minimum. The motor cable shield

must be connected to the metal cabinets of the adjust-

VLT

®

2800 Series

MG.27.A2.22 - VLT

®

is a registered Danfoss trademark 19

Installation

Loading...

Loading...